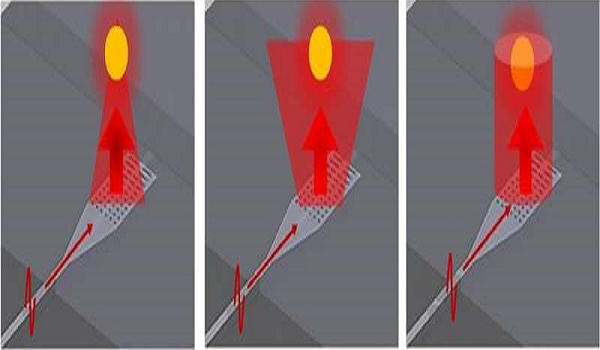

MIT researchers have created a powerful nanoscale flashlight on a chip, which could transform cell phones into sensors capable of detecting viruses and other minute objects. Their approach to designing the tiny light beam on a chip could also be used to create a variety of other nano flashlights with varying beam characteristics for various applications. Consider a wide spotlight versus a light beam focused on a single point.

Light has long been used by scientists to identify materials by observing how the light interacts with the material. They accomplish this by essentially shining a light beam on the material and then analyzing the light after it passes through the material. Because all materials interact differently with light, analyzing the light that passes through the material provides a kind of “fingerprint” for that material. Consider doing this for a variety of colors, i.e. different wavelengths of light, and capturing the interaction of light with the material for each color. This would result in a more detailed fingerprint.

MIT researchers have built a powerful nanoscale flashlight on a chip. It could set aside cell phones into sensors capable of detecting viruses and other minuscule objects.

The majority of these instruments, known as spectrometers, are quite large. There would be several advantages to making them much smaller. They could, for example, be portable and have additional applications (imagine a futuristic cell phone loaded with a self-contained sensor for specific gas). While researchers have made significant progress in miniaturizing the sensor for detecting and analyzing the light that has passed through a given material, creating a miniaturized and appropriately shaped light beam—or flashlight—remains a challenge. Today, that light beam is typically provided by macroscale equipment, such as a laser system, which is not built into the chip itself, as sensors are.

Complete Sensor

Enter the MIT project. The team describes not only their approach for designing on-chip flashlights with a variety of beam characteristics in two recent papers published in Nature Scientific Reports, but they also report building and successfully testing a prototype. They created the device using existing fabrication technologies familiar to the microelectronics industry, so they are confident that the approach could be deployed at a mass scale at a lower cost.

Overall, this could allow the industry to develop a complete sensor on a chip that includes both a light source and a detector. As a result, the work represents a significant advancement in the use of silicon photonics for lightwave manipulation on microchips for sensor applications.

“This work is significant because it represents a new paradigm of photonic device design, enabling improvements in optical beam manipulation,” says Dawn Tan, an associate professor at Singapore University of Technology and Design who was not involved in the research.

“Silicon photonics has enormous potential for improving and miniaturizing current bench-scale biosensing schemes. To realize its full potential, we simply need smarter design strategies. This work exemplifies one such approach “Robin Singh, the lead author of both papers, explains. Singh received his MS (2018) and Ph.D. (2020) in mechanical engineering from MIT.

Anuradha Murthy Agarwal, a principal research scientist in MIT’s Materials Research Laboratory, and Brian W. Anthony, a principal research scientist in MIT’s Department of Mechanical Engineering, are senior coauthors on the first paper. Agarwal, Anthony, Yuqi Nie, now at Princeton University, and Mingye Gao, a graduate student in MIT’s Department of Electrical Engineering and Computer Science, are Singh’s coauthors on the second paper.

How They Did It

Singh and his colleagues used a variety of computer modeling tools to create their overall design. These included traditional approaches based on the physics of light propagation and manipulation, as well as more cutting-edge machine-learning techniques that teach the computer to predict potential solutions using massive amounts of data. “If we show the computer a lot of examples of nano flashlights, it will learn how to make better flashlights,” Anthony explains. Finally, “we can tell the computer the pattern of light that we want, and it will tell us what the flashlight design needs to be.”

All of these modeling tools have advantages and disadvantages; together they resulted in a final, optimal design that can be adapted to create flashlights with different kinds of light beams.

The researchers then used that design to create a flashlight with a collimated beam, or light rays that are perfectly parallel to each other. Collimated beams are essential for certain types of sensors. The overall flashlight created by the researchers included 500 rectangular nanoscale structures of varying dimensions that the team’s modeling predicted would allow for a collimated beam. Different dimensional nanostructures would result in different types of beams, which would then be important in other applications.

The tiny flashlight with a collimated beam worked. Not only that, it provided a beam that was five times more powerful than is possible with conventional structures. That’s partly because “being able to control the light better means that less is scattered and lost,” says Agarwal.

Singh describes the thrill he felt when he created his first flashlight. “It was amazing to see what I had designed on a computer through a microscope. Then we put it to the test, and it worked!” The MIT Skoltech Initiative helped fund some of this research. Agarwal credits her colleagues at the Microphotonics Center and the Initiative for Knowledge and Innovation in Manufacturing (IKIM) for providing a fertile intellectual environment for this work.

The Department of Materials Science and Engineering, the Materials Research Laboratory, the Institute for Medical Engineering & Science, and MIT.nano were also instrumental in making this work possible.