A machine-tool dynamometer is a device for measuring cutting forces and torque during machining processes. It is a multi-component dynamometer that is used to measure forces when operating the machine tool. It is a critical instrument in the manufacturing and machining industries, giving useful data for optimizing machining processes, assessing tool performance, and guaranteeing quality control. These machine tool dynamometers allow experimental cross-checking and verification of empirical estimations for these forces.

Here’s how it typically works:

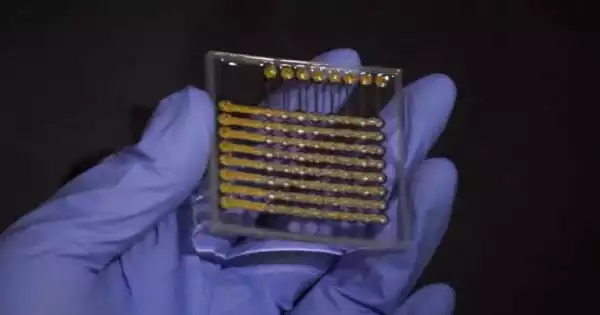

- Installation: The dynamometer is installed in the tool holder or the spindle of the machine tool, usually between the tool and the workpiece.

- Measurement: As the cutting tool engages with the workpiece, the dynamometer measures the cutting forces (tangential, radial, and axial forces) and torque applied to the tool.

- Data Collection: The dynamometer generates real-time data, which can include force and torque values as well as other parameters such as tool vibration and temperature.

- Analysis: The collected data is then analyzed to assess the efficiency of the machining process, detect any anomalies or tool wear, and make adjustments to optimize the process parameters.

Machine-tool dynamometers are increasingly being utilized to precisely monitor forces and optimize the machining process as technology develops. Depending on the coordinate system used, these multi-component forces are quantified as separate component forces in each co-ordinate. Machining forces are determined by the depth of cut, feed rate, cutting speed, tool material and shape, work piece material, and other parameters like as lubrication/cooling.

Machine-tool dynamometers are essential for a variety of machining operations, including milling, turning, drilling and grinding. They assist firms in increasing productivity, decreasing production costs, extending tool life, and improving machined component quality. Furthermore, they play an important part in research and development activities aimed at improving machining methods and materials.