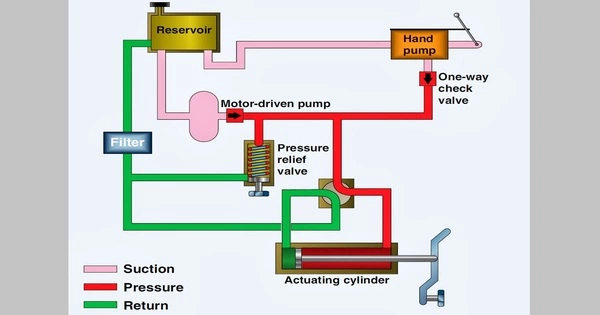

A hydraulic circuit is a system made up of a series of interconnected discrete components that move liquid. It is a system that transmits power and does mechanical work by using a pressurized fluid, often oil. It is an essential component in a wide range of industrial and mobile machinery applications.

Hydraulic circuits are widely found in construction equipment, manufacturing machinery, airplanes, and a variety of other applications requiring accurate and powerful motion control. This system’s function could be to regulate where fluid flows (as in a network of cooling tubes in a thermodynamic system) or to control fluid pressure (as in hydraulic amplifiers). Hydraulic machinery, for example, uses hydraulic circuits to move large loads (in which hydraulic fluid is forced under pressure through hydraulic pumps, pipelines, tubes, hoses, hydraulic motors, hydraulic cylinders, and so on).

Here are the key components and concepts in a typical hydraulic circuit:

- Hydraulic Fluid: Hydraulic circuits use a specialized hydraulic fluid, usually oil, which is pressurized to transmit force. This fluid is chosen for its lubricating properties, high density, and ability to handle high pressures and temperatures.

- Pump: The hydraulic pump is responsible for creating the fluid pressure. It draws in hydraulic fluid from a reservoir and pressurizes it. There are various types of hydraulic pumps, including gear pumps, vane pumps, and piston pumps.

- Reservoir: The reservoir stores the hydraulic fluid, provides a place for excess fluid to return to, and helps cool the fluid. It also typically contains a filter to remove contaminants from the fluid.

- Actuators: Actuators are devices that convert hydraulic pressure into mechanical force or motion. Common hydraulic actuators include hydraulic cylinders and hydraulic motors.

- Hydraulic Lines: These are the pipes or hoses that carry hydraulic fluid between the various components of the circuit.

- Accumulator: An accumulator stores hydraulic energy in the form of pressurized fluid. It can be used to provide extra power during peak demand or to absorb shock loads.

The success of electrical circuit theory inspired the concept of defining a fluid system in terms of discrete components. Hydraulic circuit theory, like electric circuit theory, works best when the elements (passive components like pipes or transmission lines or active components like power packs or pumps) are discrete and linear. This typically indicates that hydraulic circuit analysis is best suited to long, thin tubes with discrete pumps, such as those seen in chemical process flow systems or microscale devices.

A hydraulic circuit’s operation entails managing the flow of hydraulic fluid to and from actuators in order to do the desired mechanical work. In a hydraulic excavator, for example, the operator can use the hydraulic controls to control the boom, arm, and bucket movements.

Hydraulic circuits are well-known for their high power density, accurate control, and long-distance power transmission. They are commonly employed in applications where strong force, precision control, or resistance to extreme weather conditions make electric or mechanical systems ineffective.