Thanks to recent improvements in battery design, electric vertical takeoff and landing (eVTOL) vehicles, the flying automobiles and mobility devices that were once the stuff of science fiction, could become a reality in the near future. The twenty-first century promised jet packs, robot servants, and flying automobiles. A team of Penn State University academics investigating the ability of batteries to power such electronic flying vehicles believes that futuristic technology is already feasible.

“I think flying cars have the potential to eliminate a lot of time and increase productivity and open the sky corridors to transportation,” said Chao-Yang Wang, holder of the William E. Diefender Chair of Mechanical Engineering and director of the Electrochemical Engine Center, Penn State. “But electric vertical takeoff and landing vehicles are very challenging technology for the batteries.”

Electric flying cars have the potential to transform personal transportation by lowering pollution and saving time in congested locations. Opening the skies to practical passenger transportation would provide society and the economy with heretofore unimagined potential. Today (June 7, 2021) in Joule, the researchers specify the technological requirements for flying car batteries and present a prototype battery.

“Batteries for flying cars need very high energy density so that you can stay in the air,” said Wang. “And they also need very high-power during take-off and landing. It requires a lot of power to go vertically up and down.”

According to Wang, the batteries must be recharged fast in order to generate a lot of money during rush hours. He observes these vehicles take off and land frequently, as well as recharge their batteries.

“Commercially, we expect these vehicles to make 15 trips twice a day during rush hours to justify the cost of the vehicle,” Wang said. I will. “The first use will probably carry 3-4 people from the city to the airport in about 50 miles.”

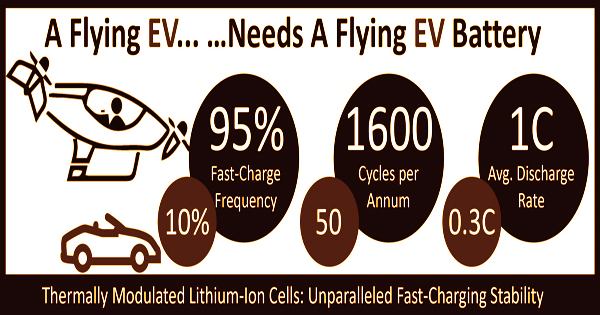

The weight of these batteries is also a consideration because the vehicle will have to lift and land them. According to Wang, once the eVTOL takes off, short journeys will average 100 miles per hour and extended excursions would average 200 miles per hour. The researchers tested two energy-dense lithium-ion batteries that can be recharged in five to ten minutes and provide enough energy for a 50-mile eVTOL ride. Almost the course of their lives, these batteries could withstand over 2,000 fast charges.

However, batteries in eVTOL vehicles face unique and significant obstacles. They require a high energy density in order for the vehicles to remain in the air long enough to be functional. They’d also have to be able to produce a lot of power during take-off and landing. Overcoming gravity is still one of the most difficult engineering problems to tackle. Batteries for eVTOL vehicles must be able to recharge quickly in addition to having a high energy density and power output capacity. These vehicles are most likely to be utilized in high-volume markets like huge cities, where they will need to take off, land, and recharge frequently.

Because they all act against each other, most battery designs include trade-offs between these three properties to some degree. High-energy-density charging slows down the process, but quick charging allows for fewer recharging cycles. Batteries for flying vehicles must also be built with minimum weight penalties, in addition to addressing these considerable obstacles. To make the most out of their batteries’ energy source, eVTOL vehicles will need to be as light as feasible.

Wang and his colleagues employed battery technology that they had been developing for electric vehicles. The idea is to heat the battery so that it can charge quickly without forming lithium spikes, which can harm the battery and be dangerous. Heating the battery, it turns out, also enables for rapid discharge of the energy stored in the battery, allowing for takeoffs and landings. The batteries are heated by integrating a nickel foil that quickly raises the temperature to 140 degrees Fahrenheit.

“Under normal circumstances, the three attributes necessary for an eVTOL battery work against each other,” said Wang. “High energy density reduces fast charging and fast charging usually reduces the number of possible recharge cycles. But we are able to do all three in a single battery.”

The researchers were successful in constructing a battery that passed their stringent requirements for batteries for eVTOL vehicles. Their high-capacity lithium-ion batteries can power a 50-mile eVTOL ride, recharge in under 10 minutes, and hold over 2,000 rapid charges before decaying. One of the most distinctive features of flying automobiles is that the batteries must always be charged. Unlike cellphone batteries, which perform best when fully depleted and recharged, a flying car battery can never be totally discharged in the air since electricity is required to stay aloft and land. There always needs to be a margin of safety in a flying car battery.

Internal resistance to charging is low when a battery is empty; however, the higher the remaining charge, the more difficult it is to transfer more energy into the battery. Recharging usually slows down when the battery fills up. Recharging time can be reduced to five to ten minutes by heating the battery.

“I hope that the work we have done in this paper will give people a solid idea that we don’t need another 20 years to finally get these vehicles,” said Wang. “I believe we have demonstrated that the eVTOL is commercially viable.”

Heating also helped to keep the battery charging time as low as possible. When a battery’s charge rises, it takes longer to charge since there is less “space” for the energy to be squeezed into. Heating the battery also allowed it to discharge its energy quickly, providing for the high power required for take-off and landing. A nickel foil was used to quickly raise the temperature to 60 ℃.

Xiao-Guang Yang and Shanhai Ge, both assistant research professors of mechanical engineering at Penn State, and Teng Liu, a doctorate student in mechanical engineering at Penn State, were also involved in this effort, as was Eric Roundtree of EC Power in State College, Pennsylvania. The research was financed by the United States Department of Energy’s Office of Energy Efficiency and Renewable Energy, the United States Air Force Small Business Technology Transfer Program, and the William E. Diefenderfer Endowment.

Information Sources: