Lithium-sulfur batteries have the potential to be a highly efficient and long-lasting power source for a wide range of applications. They offer a number of advantages over traditional lithium-ion batteries, including higher energy density, lower cost, and the ability to be safely disposed of at the end of their life.

However, there are also some challenges that need to be overcome in order to make them a practical and reliable power source, such as improving their stability and cycle life. Overall, it is likely that lithium-sulfur batteries will play a significant role in the future of energy storage, and researchers are actively working to address the remaining challenges and bring them closer to widespread use.

A research team developed and tested a new interlayer to prevent sulfur cathode dissolution in lithium-sulfur batteries. This new interlayer boosts Li-S cell capacity and keeps it stable over hundreds of cycles. Lithium-sulfur batteries could reach their full potential with a new design.

From cell phones and smart watches to the growing number of electric vehicles, batteries are ubiquitous in daily life. The majority of these devices are powered by well-known batteries”>lithium-ion battery technology. While lithium-ion batteries have come a long way since their introduction, they still have some well-known drawbacks, such as short lifetimes, overheating, and supply chain issues for certain raw materials.

These findings show that a redox-active interlayer could have a significant impact on Li-S battery development. We’re getting closer to seeing this technology in our daily lives.

Wenqian Xu

Scientists at the U.S. Department of Energy’s (DOE) Argonne National Laboratory are testing new materials in battery construction to find solutions to these problems. Sulfur is one such material. Sulfur is abundant and inexpensive, and it can store more energy than traditional ion-based batteries.

Researchers advanced sulfur-based battery research in a new study by creating a layer within the battery that adds energy storage capacity while nearly eliminating a traditional sulfur battery problem that caused corrosion.

“These results demonstrate that a redox-active interlayer could have a huge impact on Li-S battery development. We’re one step closer to seeing this technology in our everyday lives.” – Wenqian Xu, a beamline scientist at APS

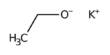

A promising battery design pairs a sulfur-containing positive electrode (cathode) with a lithium metal negative electrode (anode). In between those components is the electrolyte, or the substance that allows ions to pass between the two ends of the battery.

Early lithium-sulfur (Li-S) batteries did not perform well because sulfur species (polysulfides) dissolved into the electrolyte, causing its corrosion. This polysulfide shuttling effect negatively impacts battery life and lowers the number of times the battery can be recharged.

To prevent this polysulfide shuttling, previous researchers tried placing a redox-inactive interlayer between the cathode and anode. The term “redox-inactive” means the material does not undergo reactions like those in an electrode. But this protective interlayer is heavy and dense, reducing energy storage capacity per unit weight for the battery. It also does not adequately reduce shuttling. This has proved a major barrier to the commercialization of Li-S batteries.

To address this, researchers developed and tested a porous sulfur-containing interlayer. Tests in the laboratory showed initial capacity about three times higher in Li-S cells with this active, as opposed to inactive, interlayer. More impressively, the cells with the active interlayer maintained high capacity over 700 charge-discharge cycles.

“Previous experiments with cells having the redox-inactive layer only suppressed the shuttling, but in doing so, they sacrificed the energy for a given cell weight because the layer added extra weight,” said Guiliang Xu, an Argonne chemist and co-author of the paper. “By contrast, our redox-active layer adds to energy storage capacity and suppresses the shuttle effect.”

The team conducted experiments at the 17-BM beamline of Argonne’s Advanced Photon Source (APS), a DOE Office of Science user facility, to further investigate the redox-active layer. The data gathered from exposing cells with this layer to X-ray beams allowed the team to determine the benefits of the interlayer.

The data showed that a redox-active interlayer can reduce shuttling, reduce harmful reactions within the battery, and increase the battery’s capacity to hold more charge and last for more cycles. “These findings show that a redox-active interlayer could have a significant impact on Li-S battery development,” said Wenqian Xu, an APS beamline scientist. “We’re getting closer to seeing this technology in our daily lives.”