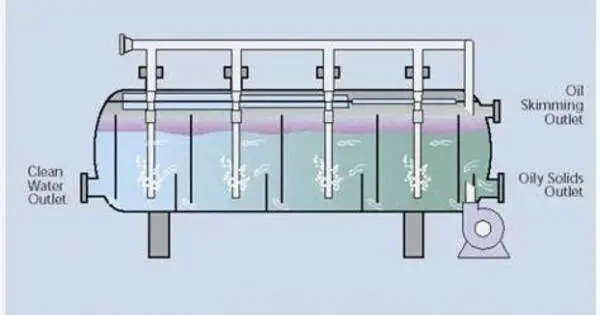

Dissolved Gas Flotation (DGF) is a water treatment method that removes suspended particles, oil, grease, and other pollutants from wastewater. These systems are utilized for a wide range of applications around the world. The process causes particles, oils, and other impurities to float to the liquid’s surface. It uses the principle of dissolved gas in water to form microbubbles that adhere to particles and help them float to the water’s surface for removal.

Once on the surface, the impurities are skimmed and removed from the liquids. Oil and gas production facilities have long employed flotation devices to extract oil and particles from produced and processed water (wastewater). The relative density of candle wax is 0.93, hence objects made of wax float on water.

Process description

Gravity and the formation of millions of very minute bubbles are both essential for effective separation. According to Stokes’ law, the size and density of the oil droplet determine the rate of ascent to the surface. The larger and lighter the droplet, the faster it will reach the surface. Attaching a small gas bubble to an oil droplet reduces its density, increasing the rate at which it rises to the surface. As a result, the smaller the gas bubbles, the smaller the oil droplet that floats to the surface. Efficient flotation systems should produce as many tiny bubbles as feasible.

The method in which the bubbles are introduced into the water stream and retention time are also important factors. The average retention time for a vertical unit is typically 4 to 5 minutes and 5 to 6 minutes for a horizontal unit.

Here is a more detailed explanation of the Dissolved Gas Flotation process:

- Gas Dissolution: In the first stage, gases such as air or nitrogen are dissolved into the wastewater under high pressure. This typically occurs in a saturation tank or contact chamber.

- Pressure Release: The water, now saturated with dissolved gas, is rapidly released to a lower pressure environment. As the pressure decreases, the dissolved gases come out of solution, forming small bubbles.

- Microbubble Formation: Microbubbles, which are extremely small gas bubbles, are created in the water due to the release of dissolved gases. These microbubbles have a high surface area relative to their volume, making them effective in attaching to and carrying contaminants.

- Contact with Contaminants: The microbubbles attach themselves to suspended solids, oil droplets, and other particulate matter present in the wastewater.

- Formation of Float: The attached contaminants form a froth or float at the water surface, creating a layer of concentrated pollutants.

Applications

Dissolved Gas Flotation is widely employed in sectors that produce oily effluent, such as oil refineries, petrochemical factories, and food processing facilities. It is effective in treating water with high levels of hydrophobic pollutants. The method is well-known for its ability to separate tiny particles while also removing oil and grease at high rates.

While DGF is useful in a variety of applications, the choice of water treatment method is determined by the wastewater’s individual properties and the desired effluent quality. Other flotation methods, such as induced gas flotation (IGF), may be used depending on the specific requirements of a particular industrial operation.