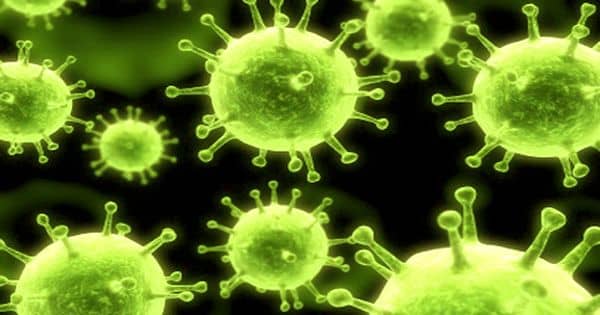

Although several antifogging surfaces have been created successfully, creating a surface with both antifogging and frost-resistant qualities remains a significant issue because condensed water eventually forms an ice layer under freezing temperatures. Engineers have created a more durable alternative to traditional deicers.

Airports are often congested, especially during the winter. Delays get longer while passengers wait to board because planes need to be dowsed with hundreds of gallons of deicing fluids to help them combat the freezing winter. However, as soon as the plane takes off, the majority of the liquid is removed off the aircraft’s surface and ends up damaging freshwater streams and lakes.

Sushant Anand, UIC assistant professor of mechanical engineering, and Rukmava Chatterjee, a UIC Ph.D. student, have created a longer-lasting alternative to conventional deicers in an effort to make a more efficient product immune to ice for such demanding sectors and consumers. According to them, it might also aid other industries.

Our coatings are an all-in-one package that can postpone frost development for extended hours while also causing any ice created on its surface to quickly shed off by a light wind or simple substrate tilting.

Rukmava Chatterjee

“We questioned the cryoprotectants’ lifetime and sought for new ways to boost their effectiveness,” Anand explained. “Glycols disintegrate quickly in water and are washed away before the plane takes off, and it’s a huge problem that costs hundreds of millions of dollars, the majority of which goes down the drain.” We reasoned that why not improve such chemicals and create alternatives that are more biofriendly while lasting longer? And that is what we ended up doing.”

To achieve this goal, the researchers created an extended family of more than 80 anti-freezing coatings, which can be classed as polymeric solutions, emulsions, creams, and gels. The formulas can be easily applied to aluminum, steel, copper, glass, plastic, or any industrial surface without preconditioning or costly surface treatments.

“Our coatings are an all-in-one package that can postpone frost development for extended hours while also causing any ice created on its surface to quickly shed off by a light wind or simple substrate tilting,” Chatterjee added.

Their work is reported in an Advanced Materials article titled “A family of frost-resistant and icephobic coatings.”

The coatings are a class of phase transition material-based formulations and multifunctional coatings capable of tailoring solid foulant adherence to functional surfaces ranging from ice to bacteria, regardless of their intrinsic material structure and chemistry. This was accomplished by controlling how chemicals leach out of the material system and by developing a lubricating surface layer that is both slippery and non-freezing in nature.

The anti-freezing gels are also clear, which is important for applications such as traffic signals, runway lights that help pilots during landings, vehicle windshields, and building windows.

“Imagine covering your smartwatch with our gel, which can limit ice formation in cold negatives while also preventing bacterial contamination,” Chatterjee explained.

“Because our anti-icing sprays are bio-friendly and anti-bacterial, we believe they have the potential to be used in agriculture to protect crops from severe frost damage,” Anand added. “However, that is a pipe dream, and we need to conduct more research to see if there will be any long-term negative effects on the plants.”

UIC’s Office of Technology Management has filed a worldwide patent application titled “Compositions and Methods for Inhibiting Ice Formation on Surfaces.” “These materials have immense potential for numerous applications, and I believe the day when commercial versions of our materials are available has just gotten closer,” Anand added.

Hassan Bararnia and Umesh Chaudhuri of the Anand Research Group assisted Chatterjee with the experiments.