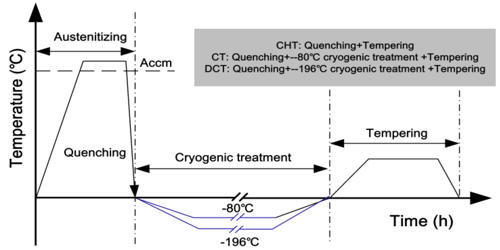

Cryogenic treatment is the process of cooling materials to cryogenic temperatures temporarily to improve their material properties at room temperature. It is the process of treating workpieces to cryogenic temperatures (i.e. below −190 °C (−310 °F)) in order to remove residual stresses and improve wear resistance on steels and even composites. Cryogenic hardening is a process that uses cryogenic temperatures – temperatures below −238 F. (−150 C.) to strengthen and enhance the grain structure of a metal. In addition to seeking enhanced stress relief and stabilization, or wear resistance, cryogenic treatment is also sought for its ability to improve corrosion resistance by precipitating micro-fine eta carbides, which can be measured before and after in a part using a quantimet. This treatment is performed by slowly cooling the parts in a controlled bath of liquid nitrogen or other refrigerants, and holding the parts until the temperature has reached the target temperature, then returning the part to room temperature. This is distinct from cooling materials down to cryogenic temperatures to take advantage of phenomena such as superconductivity that only occur at cryogenic temperatures.

The process has a wide range of applications from industrial tooling to the improvement of musical signal transmission. It is a very active area of research that has produced many reproducible and industrially useful results. It is when tools and other heat-treated metals are cooled to very cold temperatures, -120°F or below, unstable phases are transformed, making the part very stable at normal use temperatures. It has shown significant changes in the microstructure and mechanical properties of materials. Cryogenic treatments were first commercialized in the mid-to-late 1960s.

Some of the benefits of cryogenic treatment include longer part life, less failure due to cracking, improved thermal properties, better electrical properties including less electrical resistance, reduced coefficient of friction, less creep and walk, improved flatness, and easier machining.

Cryogenic treatment of certain metals is known to provide three beneficial effects:

- Greater durability: Cryogenic treatment helps to promote the transformation of retained austenite present in heat-treated steels into harder martensite steel. It changes the entire structure of a metal, not just the surface. So the benefits are not lost as a result of further processing, such as grinding.

- Improved wear resistance: Cryogenic hardening increases the precipitation of eta-carbides. It is also used to treat cast iron, copper alloys, aluminum, and magnesium. These are fine carbides that act as binders to support the martensite matrix, helping to resist wear and corrosion resistance.

- Stress relief: All metals have residual stress that is created when it solidifies from its liquid phase into a solid phase. Cryogenic treatment can reduce these weaknesses by creating a more uniform grain structure.

Other benefits –

- Increases resistance to abrasive wear,

- Improves the microstructure of the metal, not just the surface,

- Parts may be subsequently reground or machined without affecting the results of the cryogenic process,

- Decreases residual stresses, while increasing toughness and dimensional stability,

- Improves resistance to impact.