A coal-fired thermal power station is a power plant in which the prime mover is steam-driven. A coal burner (or pulverized coal burner) is a mechanical device that burns pulverized coal (also known as powdered coal or coal dust since it is as fine as face powder in cosmetic makeup) into a flame in a controlled manner. It is a device that burns charcoal, like a stove or brazier.

A coal burner is mainly composed of a pulverized coal machine, a host of combustion machines (including a combustion chamber, automatic back and forth motion system, automatic rotation system, the combustion air supply system) control system, an ignition system, the crater, and others.

Mechanism

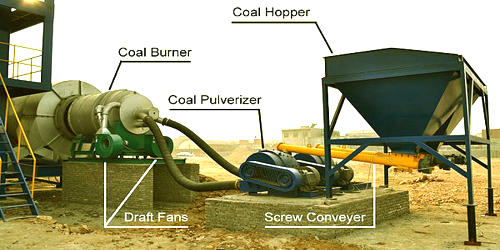

In the worksite, a coal burner works with the coal pulverizer and coal hopper usually. The coal in the hopper is conveyed to the coal pulverizer by a screw conveyor. The coal pulverizer will crush the coal into pulverized coal. Water is heated, turns into steam, and spins a steam turbine, which drives an electrical generator. In the coal burner, the pulverized coal mixes with air (High-speed airflow is generated by the draft fan on the coal burner), and is ignited by the oil-burning igniter. After it passes through the turbine (one to three-stage), the steam is condensed in a condenser and recycled to where it was heated; this is known as a Rankine cycle.

Fig: Pulverized Coal Burner

Ignition

There are mainly two ways to ignite the coal burner. The manual way and automatic way, no matter which way it adopts, the coal burner often needs fuel (oil, gas, etc.) as the combustion medium. It is predominantly adopted in large coal-fired utility boilers. The finer the grinding of coal, the more efficient its combustion. The difference is that the high-energy ignition devices which generate sparks replace people’s hands. The heart of a pulverized coal-fired boiler is the pulverizer, also known as the mill.

Use

Pulverized coal can be used as a reducing agent by injecting it through the tuyeres. Pulverized coal burners have a wide range of uses in industrial production and daily life, such as providing heat for boilers, hot mix asphalt plant, cement kiln, metal furnace, annealing, quenching furnace, precision casting shell burning furnace, melting furnace, forging furnace and other heating furnace or kiln. Depending on speed pulverizers are classified as low-speed, medium-speed, and high-speed mills. Pulverized coal burners may be located on the front or opposed walls or in the corners of the furnace.