Calcium oxide (CaO), also known as quicklime or burnt lime, is a solid with a high affinity for water, which means it can react with water in the air, on our skin, or anywhere else it can to form calcium hydroxide. It’s a common chemical compound that comes in the form of hard lumps that are odorless, white, or gray-white. The term “lime” refers to calcium-containing inorganic materials that are primarily composed of carbonates, oxides, and hydroxides of calcium, silicon, magnesium, aluminum, and iron. Since lime reacts so readily with water (to form hydrated lime) and carbon dioxide, it does not occur naturally (to form limestone). Calcination at temperatures of 1,700-2,450°C produces it from calcium carbonate, limestone, or oyster shells.

Free lime is calcium oxide that has not been processed and has not reacted in construction materials such as cement. It belongs to the calcium oxides class, which contains calcium and oxygen in a 1:1 ratio and serves as a fertilizer. Calcium oxide’s reaction with water is exothermic, meaning it releases a lot of heat when reacting. As a result, in addition to being corrosive and causing substantial skin irritation, it can also cause burns. Calcium hydroxide is calcium oxide that has been hydrated. It is corrosive since it is alkali; in solution, it produces limewater. Quicklime is relatively inexpensive. It is a commodity chemical, as is a chemical derivative (calcium hydroxide, of which quicklime is the base anhydride).

Calcium oxide (CaO) is not found pure in nature, but is found in a variety of common minerals (e.g., calcite, aragonite, limestone, and marble), which differ greatly in purity (impurities usually include magnesia, iron, alumina, silica, sulfur). Iron and sulfur are the most problematic of these (i.e., where clarity is important in glass). Calcium oxide is typically produced in a lime kiln by the thermal decomposition of calcium carbonate (CaCO3; mineral calcite)-containing materials such as limestone or seashells.

Calcium oxide has a medium viscosity, a high surface tension, and a quick to medium rate of expansion and contraction. This is done by heating the substance to above 825 °C (1,517 °F), a method known as calcination or lime-burning, which releases a molecule of carbon dioxide (CO2) and leaves quicklime.

CaCO3(s) → CaO(s) + CO2(g)

Calcium oxide has a mild impact on color, unless it is used in large quantities, in which case it can bleach iron oxide. It comes in a variety of colors, including kaki/tomato reds. Quicklime is unstable and, when cooled, can naturally react with CO2 from the air until it is fully converted back to calcium carbonate after a period of time, unless it is slaked with water to set as lime plaster or lime mortar. The degree of crystallization and cohesion of the crystalline mass, as well as the homogeneity of the matrix, differ between lime minerals.

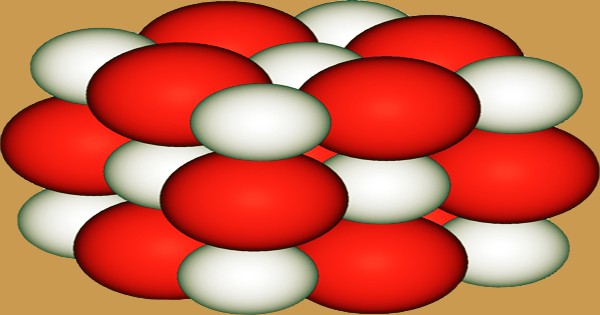

Quicklime production is estimated to be around 283 million tonnes per year worldwide. With a total output of about 170 million tonnes per year, China is by far the world’s largest producer. With about 20 million tonnes per year, the United States is the next largest producer. One calcium cation (with a charge of +2) and one oxygen anion make up a calcium oxide molecule (which holds a charge of -2). It is the primary flux in medium and high-temperature glazes, with activity starting around 1100°C (within the glaze). In high-fire bodies, it must be used with caution because its aggressive fluxing action can result in a body that is too volatile (melting if slightly overfired).

For every 1.0 t of quicklime, around 1.8 t of limestone is needed. Quicklime has a higher affinity for water than silica gel and is thus a more effective desiccant. The reaction of quicklime with water is correlated with a volume increase of at least 2.5 times. In building, including finishing and masons lime; metallurgy, primarily as a flux in steel production; kraft paper pulp production; ammonia recovery in the sodium carbonate solvay process; sewage and trade waste treatment; water purification and softening; miscellaneous applications. As a result, calcium oxide is an ionic compound that contains an ionic bond between calcium and oxygen.

Calcium oxide, or CaO, is a granular powder that comes in white or grayish-white lumps. It has a yellowish or brownish hue due to the presence of iron. Calcium hydroxide is the chemical term for lime water, which has the formula Ca(OH)2. When water is added to lime, the following reaction occurs: calcium hydroxide Ca(OH)2 is formed.

CaO + H2O → Ca(OH)2

Lime is a common term for many calcium compounds as well as an adjective to describe various types of lime. Lime, also known as quicklime or burnt lime, is equated with the compound calcium oxide in this entry. Hydrated lime, also known as slaked lime (Ca(OH)2), is calcium hydroxide that is formed by mixing lime with water. Magnesium and calcium are also present in dolomite limes. Quicklime is primarily used in the basic oxygen steelmaking (BOS) process. Its weight per ton of steel ranges between 30 and 50 kilograms (65–110 lb). The acidic oxides, SiO2, Al2O3, and Fe2O3, are neutralized by quicklime, resulting in a basic molten slag.

Continuous shaft kilns filled with alternate layers of crushed limestone and coal or anthracite are used in modern processes. At temperatures above 1,000°C, efficient calcium oxide production is preferred. Lime was made by heating limestone over an open fire in prehistoric times. Lime was produced over time in lined pits and kilns. Since the 17th century, brick lime kilns have been widely constructed, and the technology for producing lime has remained relatively unchanged. Clay-containing soils can benefit from quicklime and hydrated lime, which can greatly improve their load carrying ability. They do this by combining finely divided silica and alumina to form calcium silicates and aluminates, which have cementing properties.

Calcium oxide is used to make calcium carbide, soda ash, bleaching powder, construction materials, refractoriness, desiccant, soil conditioner, and calcium fertilizer, among other things. It can be used as a fluorescence powder production flux and as an analysis reagent. Other methods that use small amounts of quicklime include the manufacture of glass, calcium aluminate cement, and organic chemicals. Metal, pesticides, pharmaceuticals, non-ferrous metals, fertilizers, leather, and the manufacture of calcium hydroxide, as well as the drying of laboratory ammonia, carbon dioxide absorbent, and alcohol dehydration can all benefit from calcium oxide.

If this chemical comes into contact with the eyes, rinse them thoroughly with plenty of water, periodically raising the lower and upper lids. Get medical help right away. If this chemical comes into contact with your skin, flush it with water right away. If this chemical gets into your clothes, take them off right away and wash your skin with water. Calcium oxide is also used as a refractory substance, a binding agent in bricks, and as a component of plaster, mortar, stucco, and other construction materials. A labora, a dehydrating agent, and a flux in steel production.

Information Sources: