Aluminium nitride (AlN) is a solid aluminium nitride. It is produced through the carbothermal reduction of alumina or direct nitridation of aluminum. It is an electrical insulator and has a high thermal conductivity of up to 321 W/(m•K). Its wurtzite phase (w-AlN) has a bandgap of ~6 eV at room temperature and could be used in optoelectronics operating at deep ultraviolet frequencies. It is an excellent material to use when high thermal conductivity and electrical insulation are required, making it ideal for use in thermal management and electrical applications.

Properties

It has a density of 3.26 g.cm-3 and, while it does not melt, it dissociates at temperatures above 2500 °C under atmospheric pressure. The material is covalently bonded and sintering resistant without the use of liquid-forming additives.

- Molar Mass/Molecular Weight: 40.989 g/mol

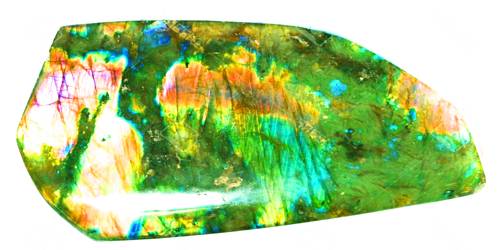

- Color and Appearance: White to pale yellow powder or sheet

- Melting Point: 2200 °C, 3990 °F

- Boiling Point: 2517 °C, 4563 °F

- Density: 2.9-3.3 g cm-3

- Solubility: Slightly soluble in mineral acids, decompose in water solutions containing acids and bases

- Hardness: 1100 Kg/mm2

Stability

Aluminium nitride is stable at high temperatures in inert atmospheres and melts at around 2200 degrees Celsius. At ~1800 °C, AlN decomposes in a vacuum. Surface oxidation occurs in the air above 700 °C, and surface oxide layers of 5-10 nm thickness have been detected at room temperature. This oxide layer protects the material from temperatures as high as 1370 °C. Above this temperature, bulk oxidation takes place. Up to 980 °C, aluminium nitride is stable in hydrogen and carbon dioxide atmospheres.

The material dissolves slowly in mineral acids due to grain-boundary attack, and it dissolves quickly in strong alkalies due to attack on the aluminum-nitride grains. In water, the material hydrolyzes slowly. Most molten salts, including chlorides and cryolite, do not attack aluminium nitride.

A Cl2-based reactive ion etches can be used to pattern aluminum nitride.

Preparation

Its synthesis involves carbothermal reduction of aluminum oxide (Al2O3) using gaseous nitrogen at a temperature of 1400-1700°C:

Al2O3 + C → Al2O2 + CO

Al2O2 + 2C + N2 → 2AlN + 2CO

Sintering aids like CaO or Y2O3 are used, and then the mix is hot pressed to produce the dense technical-grade material.

Applications

Aluminum Nitride has a coefficient of thermal expansion and electrical insulation properties that are similar to those of silicon wafer material, making it a useful material for electronics applications where high temperatures and heat dissipation are frequent issues.

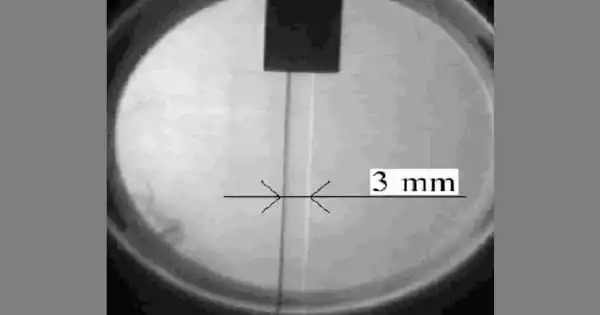

AlN is also used in the fabrication of piezoelectric micromachined ultrasound transducers that emit and receive an ultrasound and can be used for in-air rangefinding over distances of up to a meter.

There are metallization methods available to enable AlN to be used in electronics applications similar to alumina and beryllium oxide. AlN nanotubes, which are isoelectronic with carbon nanotubes and are inorganic quasi-one-dimensional nanotubes, have been proposed as chemical sensors for toxic gases.

There is currently a lot of research going on to develop light-emitting diodes that operate in the ultraviolet using gallium nitride-based semiconductors, and wavelengths as short as 250 nm have been achieved using the alloy aluminium gallium nitride.

Among the applications of AlN are –

- opto-electronics,

- dielectric layers in optical storage media,

- electronic substrates, chip carriers where high thermal conductivity is essential,

- military applications,

- as a crucible to grow crystals of gallium arsenide,

- steel and semiconductor manufacturing.