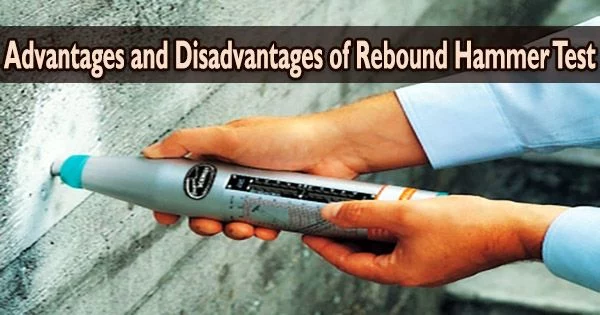

Concrete can be tested non-destructively using the Rebound Hammer Test, which gives a quick, accurate measure of the material’s compressive strength. The rebound hammer, which is also known as a Schmidt hammer, is made out of a mass controlled by a spring that travels along a plunger inside of a tubular housing.

A spring-controlled mass with consistent energy is made to hit the surface of the concrete when the plunger of the rebound hammer is pressed against it. On a graded scale, the amount of rebound, which measures surface hardness, is measured. This measured value is designated as Rebound Number (rebound index).

Low strength and stiffness concrete will absorb more energy, resulting in a lower rebound value. The premise behind the rebound hammer test method is that an elastic mass’ ability to rebound is dependent on how hard the concrete surface it strikes is.

Points to Remember in Rebound Hammer Test:

- The concrete surface should be smooth, clean and dry.

- Ant loose particles should be rubbed off from the concrete surface with a grinding wheel or stone, before hammer testing.

- Rebound hammer test should not be conducted on rough surfaces as a result of incomplete compaction, loss of grout, spalled or tooled concrete surface.

- The point of impact of rebound hammer on concrete surface should be at least 20mm away from edge or shape discontinuity.

- At each point of testing, six measurements of the rebound number are taken, and the average of those readings is used to calculate the rebound index for the corresponding place of observation on the concrete surface.

Advantages and Disadvantages of Rebound Hammer Test –

The advantages of Rebound hammer tests are:

- Apparatus is easy to use

- Determines uniformity properties of the surface

- The equipment used is inexpensive

- Used for the rehabilitation of old monuments

The disadvantages of Rebound Hammer Test are:

- The results obtained is based on a local point

- The test results are not directly related to the strength and the deformation property of the surface

- The probe and spring arrangement will require regular cleaning and maintenance

- Flaws cannot be detected with accuracy

Factors Influencing Rebound Hammer Test

Below mentioned are the important factors that influence rebound hammer test:

- Type of Aggregate

- Type of Cement

- Surface and moisture condition of the concrete

- Curing and Age of concrete

- Carbonation of concrete surface

Type of Aggregate

With the usage of various aggregates, the relationship between the compressive strength of concrete and the rebound number will change. By using typical aggregates, such as gravel and crushed aggregate, regular correlations in the data are achieved. It will take special calibration to put lightweight aggregates through the test.

Type of Cement

The concrete made of high alumina cement ought to have higher compressive strength compared to Ordinary portland cement. The use of supersulphated cement in concrete decrease the compressive strength by 50% compared to that of OPC.

Type of Surface and Moisture Condition

Compared to open texture concrete, close texture concrete performs better in the rebound hammer test. Concrete with large honeycombs and concrete without particles is not appropriate for rebound hammer testing. When comparing floating or trowelled surfaces to moulded surfaces, the test overestimates the strength. If tested, a wet concrete surface will yield a lower strength value. This underestimation of strength can go lower to 20% that of dry concrete.

Type of curing and age of concrete

The relationship between concrete’s strength and hardness will evolve throughout time. This interaction is also impacted by how concrete cures and is exposed to moisture. For concrete with an age between 3days to 90 days is exempted from the effect of age. For greater aged concrete special calibrated curves is necessary.

Carbonation on Concrete Surface

A higher strength is estimated by the rebound hammer on a concrete that is subjected to carbonation. It is estimated to be 50% higher. As a result, the carbonated layer must be removed from the concrete before the rebound hammer test can be performed.