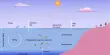

An innovative acid-based electrochemical technique for the conversion of CO2 taken from emission sources or straight from air has been created by an international team of researchers at the Universities of Sydney and Toronto.

With the Australian Academy of Science last week publishing a study emphasising the necessity of linking carbon capture with a reduction in emissions to contain global warming at 1.5 °C, carbon capture and conversion is gathering momentum on a global scale.

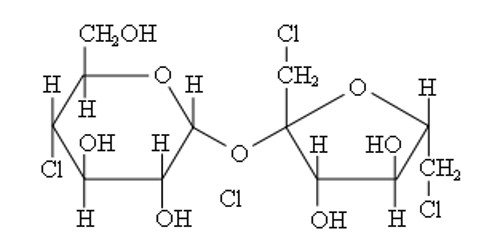

When converting CO2 to multicarbon products like ethylene and ethanol, the new method, which was published in Nature Synthesis, improves energy efficiency by a factor of two when compared to the team’s earlier benchmark work because it uses an acidic chemical rather than an alkaline or neutral reactive one.

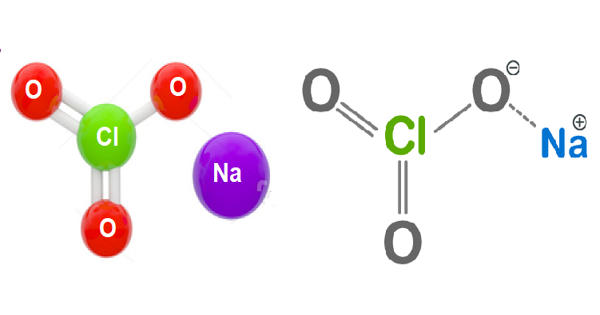

Multicarbon compounds are widely utilized chemicals and raw materials in industry, and they are most frequently obtained from oil extraction. The raw material for polyethylene, a plastic used in everything from packaging to medications, is ethylene.

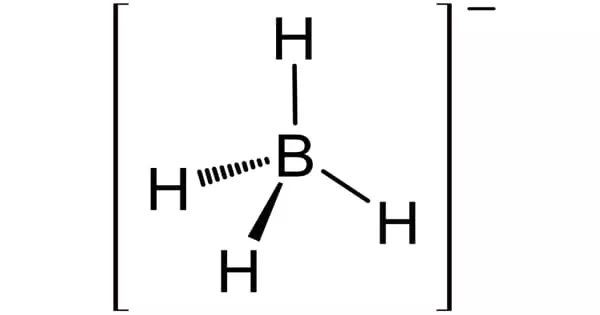

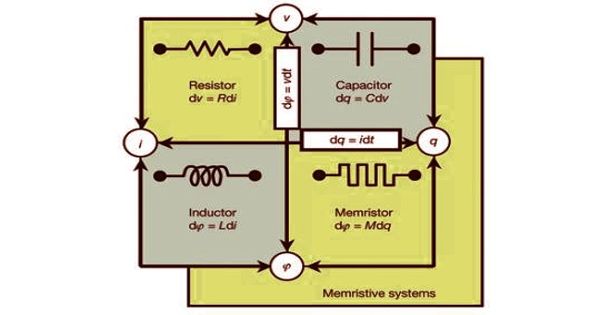

The catalyst functions by introducing an acidic electrolyte, which uses more carbon for conversion than alkaline-based solutions. The catalyst converts CO2 into multicarbon compounds when subjected to electrical treatment.

Governments and industry are becoming increasingly aware of the necessity of carbon capture, but conversion is not just a ‘nice to have’. By converting CO2, rather than simply capturing and burying it, we can create fully circular carbon economies, potentially reducing the reliance of oil extraction to create ethylene.

Dr. Yong Zhao

“Our catalyst system allows for more multicarbon products to be converted from CO2, essentially giving carbon capture more ‘bang for buck’ by creating a secondary market of materials,” said Dr. Fengwang Li, a corresponding author from the School of Chemical and Biomolecular Engineering.

“However, until now, converting CO2 into multicarbon products in acidic media has been challenging. Using an adlayer system, the catalyst acquires a reactive environment that is favorable for multicarbon formation at an energy-efficient operating condition,” Dr. Li said.

The study’s lead author, research scientist at the CSIRO Energy Centre, Dr. Yong Zhao said, “Governments and industry are becoming increasingly aware of the necessity of carbon capture, but conversion is not just a ‘nice to have’. By converting CO2, rather than simply capturing and burying it, we can create fully circular carbon economies, potentially reducing the reliance of oil extraction to create ethylene.”

“This process is an important step towards creating large-scale carbon capture and conversion systems that turn carbon capture into a value-add industry, thereby increasing its financial viability and creating a more solid commercial basis for carbon removals,” said Dr. Zhao, who conducted the research while at the University of Sydney.

“While the overall goal worldwide should be to slash emissions by transitioning to renewables and moving away from the burning of fossil fuels, the transition for heavy industry will take time, making the capturing of CO2 at the emissions site an important interim step,” he said.

The researchers will next look to again double the process’s energy efficiency. “If we want our process to be deployed at scale and used by industry, we need to double efficiency again and improve stability. That will be our key focus moving forward,” Dr. Li said.