In a recently released collaborative study, Southwest Research Institute and Sandia National Laboratories investigate the variations in oxide film formation on wrought stainless steel and additively manufactured (AM) metals in a supercritical carbon dioxide (sCO2) environment.

Carbon dioxide that has been kept at a temperature and pressure that causes it to combine the characteristics of a gas and a liquid is known as sCO2. Water is frequently used as a thermal medium in power cycles in modern power plants.

Up to 10% more efficiency can be achieved by replacing water with sCO2, which also enables significantly smaller turbomachinery and a lesser environmental impact. Since of its supercritical state, sCO2 is an extremely effective fluid for power generation because even minor changes in temperature or pressure result in large changes in density.

Leading the way in sCO2 power cycles is SwRI. In addition to the 10 MWe Supercritical Transformational Electric Power (STEP) Pilot Plant being built at SwRI, the Institute has received multiple Department of Energy and industry-funded projects to deploy pilot-scale sCO2 power cycle components and system-level equipment.

As part of an ongoing sCO2 collaboration project with Sandia National Laboratories, senior research engineer Dr. Florent Bocher started looking into how oxidation impacts AM materials.

“The smaller, more complex machinery necessary for the small turbines that sCO2 power cycles utilize makes additive manufacturing an attractive resource,” Bocher said.

Additive manufacturing is a cutting-edge technique that builds an item by layering plastic, metal, and other elements for a unique, computer-generated design using 3D printing or rapid prototyping.

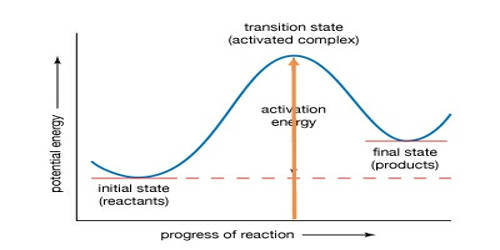

The high temperatures and pressures of the sCO2 environment make oxidation a concern for metal components. As these two industries move forward, it’s important to understand how oxidation affects them.

Dr. Florent Bocher

AM appeals to a wide range of users, including the aerospace, medical, and manufacturing industries because it produces robust components with intricate design features.

“The high temperatures and pressures of the sCO2 environment make oxidation a concern for metal components,” Bocher explained. “As these two industries move forward, it’s important to understand how oxidation affects them.”

Bocher and his colleagues subjected samples of both to a simulated sCO2 power cycle environment, which included a temperature of 450 degrees Celsius and pressure of 76 bar, for two weeks in order to compare the durability of AM metals with conventional wrought stainless steel in the sCO2 environment. Sandia National Laboratory developed and examined the AM materials.

“Both types of metals showed oxide growth,” Bocher said. “But the oxide covered about 72% of the wrought stainless steel and 54% of the AM material, with the grain size and thickness of the oxide layer being statistically larger and thicker for the wrought material. Ultimately, though, this doesn’t prove that one is more reliable than the other. More data is needed, but this certainly suggests that AM processes should be optimized going forward for these types of conditions.”

Southwest Research Institute and Sandia National Laboratories collaborated to support the project.