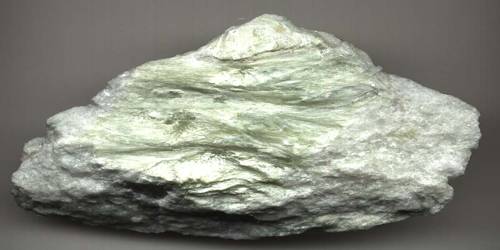

Zirconium alloys are highly desirable for nuclear applications due to their high corrosion resistance in combination with transparency to thermal energy neutrons. They are solid solutions of zirconium or other metals, a common subgroup having the trade mark Zircaloy. They are used in nuclear applications due to good corrosion resistance, resistance to irradiation damage, adequate mechanical properties, and transparency to thermal neutrons.

“Zirconium Alloys are used as fuel claddings because of their corrosion resistance to acids and bases and their low neutron-absorption rates.”

Zirconium has a very low absorption cross-section of thermal neutrons, high hardness, ductility, and corrosion resistance. The processing of Zr alloy industrial components is rather complex due to the reactivity of the metal with oxygen. One of the main uses of zirconium alloys is in nuclear technology, as a cladding of fuel rods in nuclear reactors, especially water reactors. They have a thermal conductivity of more than 30% higher than stainless.

Zirconium alloys have found the greatest use in water and vapor cooled reactors. The water cooling of reactor zirconium alloys elevates the requirement for their resistance to oxidation-related nodular corrosion. Furthermore, the oxidative reaction of zirconium with water releases hydrogen gas, which partly diffuses into the alloy and forms zirconium hydrides. Niobium, tin, iron, chromium, nickel, copper, and molybdenum are used as alloying elements; these metals are introduced in amounts ranging from fractions of a percent to 2–3 percent (total).

Applications

Zirconium alloys are corrosion resistant and biocompatible, and therefore can be used for body implants. Chemical process industry application arises from excellent resistance to a broad range of corrosives. In one particular application, a Zr-2.5Nb alloy is formed into a knee or hip implant and then oxidized to produce a hard ceramic surface for use in bearing against a polyethylene component. They are used as fuel claddings because of their corrosion resistance to acids and bases and their low neutron-absorption rates.

Zirconium alloy is used in a new ceramic knee implant. It is combined with an all-plastic tibial component, replacing the metal tray and plastic insert used in other knee replacements.

The oxidation of zirconium alloys is one of the most studied processes in all of the nuclear industry. The oxidative reaction of zirconium with water releases hydrogen gas, which partly diffuses into the alloy and forms zirconium hydrides. Reduction of zirconium demand in Russia due to nuclear demilitarization after the end of the cold war resulted in the exotic production of household zirconium items such as the vodka shot glass shown in the picture. The production of zirconium metal requires special techniques due to the particular chemical properties of zirconium.