Working Experience at Tri-star Toothbrush Company

Tri-star Toothbrush & Co. had established in 1992 with an initial investment of 50 to 60 Lacs tk. with a vision to be the market leader in the industry. It is a partnership business with 3 owners who are maintaining the overall operations of the business.

All the members are in some ways relative to each other which make it sort of a family business too. Owners are MR. Kamal Uddin, MR. Farid Uddin Ahmed & MR. Kayum.

The business was started with an entrepreneurial point of view generated from these 3 owners who were already in their own small businesses. But they were not pretty much happy about the turnover and situation of their business. Among the owners Mr. Kayum & Mr. kamal Uddin had their own cosmetic business. But Mr. Farid had just returned from UAE, Dubai with a lot of cash in hand. So, all of them had a good amount of cash to start a manufacturing plant based business in a small arena. And their dream was to get into such a business which would generate a lot of hard cash through manufacturing plant, also do some good to the society through creating opportunities for both the partners and other stake holders. One day just through a gossip turned their eyes to the toothbrush manufacturing industry and suddenly with their business experience and acumen, they realized that there is a huge demand for toothbrush in the market. The price of average toothbrush was quite high on that period around 50-60tk. per toothbrush. Only 2 companies ABC Toothbrush and Matador Co. were dominating the then toothbrush market. Actually Lord was the market leader then, they had the most advanced and sound technologies and machineries on that time. The Director of ABC toothbrush was uncle of Mr. Kamal.

So, the owners of Tri-star toothbrush & Co get pretty fascinated with the performance of ABC toothbrush and with the help of them Tri-star’s owners had gotten some very good insight about the whole manufacturing, sales & marketing process of toothbrush manufacturing. The ultimate findings came to their mind while investing such amount of money in the toothbrush business was that it only takes Plastics, rubbers and Filaments as raw materials to produce toothbrush and labor is pretty much cheap in Bangladesh, so as the land. So, their finding was how should a brush costs 50-60 tk in the market where it seems that the production cost is very low per unit.

Comprehensive Analysis of Tri-Star Toothbrush & Co.’s Supply Chain Page 8 All of these 3 owners were good risk takers by nature. Although they were earning so good in their previous business and jobs, they wanted to take this huge risk of investing 50 to 60 Lacs tk on their own. Fortunately, just within 2 to 3 year they received a turnover more than 1 crore taka which was pretty unexpected to them.

They didn’t expect that within 2 to 3 years they will receive a profit more than 200%. While with such a boost it terms of profitability, Tri-star’s owners continued to make the growth of the business with the working capital which they were receiving from huge profits. They had done some good investments within 1992-1996. They had purchased some good German and Belgium machines especially tufting machine and injection molding machines. Just to facilitate these investments they had bought machineries which costs around 1.3 to 1.5 crore taka. Through this investment in machineries Tri-star had become the market leader within 1996 in manufacturing toothbrush while Matador Co. was at second position on that time and ABC

Toothbrush was at position three. On that particular time there were only 15 distributors in the whole market and they used to sale huge amount of products of Tristar & Matador Co. Within just 4 years Tri-star captured the major market share and used to make the biggest turnovers in the market with using only those 15 distributors.

Current situation:

At present Tri-star’s owners are not anymore into their past businesses. They gradually discarded their previous businesses because they were getting very fascinated with the growth and profitability of the new toothbrush business. They get the hold of this toothbrush business very well. Up to year 2000 the business was good and they thought without investing more on the present channels, distributors, Sales Representatives and manufacturing facility will sustain the growth and make the product and fund flow like before.

They got in to trouble in the year of 2004 for the first time. They felt the pressure because on that time China Toothbrushes were introduced in the market by some importers at a very lower cost than local market rate. So, this shift of market share put a big pressure on every local toothbrush manufacturer. On that time the most frustrating thing was for local manufacturer that Chinese toothbrushes were costing on an average 10-12 taka per toothbrush where in local manufacturers were selling at 50-60 taka per toothbrush. Although these Chinese toothbrushes were lower in quality, the local price sensitive consumers were switching to these Chinese products.

As we know in Bangladesh most of the people are lower income or middle income people and these types of consumers are always price sensitive and has very less loyalty to daily commodities.

On that time, while the local toothbrush market was dwindling to sale and outrun by Chinese products, Matador Co. had came up with new strategy. Matador thought that if foreign companies can produce within such a low price why we cannot do such thing? So, Matador had invested a very big amount to purchase new machineries, expanded its production and warehousing capacity, increased its distributors and Sales Representatives in a big number to achieve economies of scale and push these products in the Retail stores. The main catch was locally produced products are easy to push within a very short amount of time while the imported items are comparatively slow to get into the market. Initially Matador incurred a huge loss because they were competing with Chinese low cost products and already they had invested a huge amount of money.

But after the change of government in 2007 Matador Co, Tri-star and other toothbrush manufacturers convinced the government through lobbing to impose some tariff on finished imported toothbrushes. Finally the government imposed 150% tariff on finished toothbrush and the wind started to blow toward the local manufacturers again. But within this time 2009 and afterward Matador had captured the toothbrush market and become the market leader through that strategy. For example after imposing the tariff Chinese importers had to sale around 25-30 taka in the market and for local companies especially for Matador Co. to produce lower than this rate was piece of cake and by this Tri-star has become second in the market and started losing market shares to Matador.

Afterward in this meantime new company arrived in the market in the year of 2002 named Alpha. This company is actually built by the General Manager from Matador. This company made huge money by importing Chinese brushes initially and afterwards in 2005 to 2006 they built their own manufacturing plant. This company started to focus on completely low price and low quality products. They attempted to capture the main portion of the market where lower income people live and anyhow ask for low price products. They started to grab the market share of lower income people. So, Tri-star again get degraded in terms of market share. At present Tri-star is at position three in this toothbrush industry.

Company’s Vision

To become a market leader without compromising high quality products and services and expand business outside local boundaries.

Company’s Mission

Regaining market share and capturing the new markets through expanding business operation to the furthest corner of the country.

Products and Services Offering

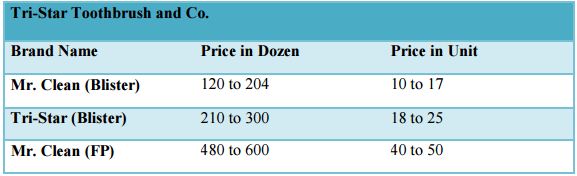

Tri-Star is a toothbrush manufacturing company. It has two brands currently available in the market. One is Mr. Clean (Blister) which is mainly for lowered income people and another one is Tri-Star which is their premium brand. All those brands are very popular to the customers.

Among these brands Tri-star Co usually go by the name “MR.CLEAN”. Among 48 types of toothbrushes, around 36 are by the name MR CLEAN. Mr. CLEAN is their main brand which moves and is popular in the market and most of the premium toothbrushes are named after either Tri-star.

The most recent and successful toothbrush in recent times is the Mr.Clean “DOREMON” kid’s toothbrush. DOREMON toothbrush was launched in the year of 2010. The mould design cost of this brush had been amortized just within 3-4 months after launching.

Competitor analysis:

In Bangladesh five companies produce Tooth brush. Along with Tri-Star tooth Brush & CO, Alpha tooth brush, Anwar Brush Company, Matador group and J.K Enterprise also produces tooth brush. Anwar Brush Company is the oldest brush company in Bangladesh and Matador Group is the largest tooth brush company in Bangladesh and the current market leader. These four brush companies are the direct competitors of Tri-Star tooth Brush and Co. and there are some indirect competitors from China, Malaysia and Thailand.

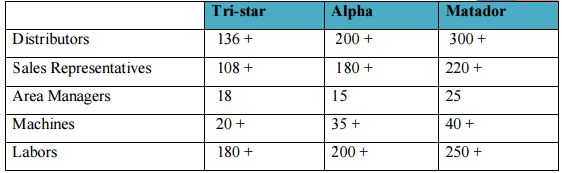

Though all of them are producing toothbrush in Bangladesh, the competition in the market is very different. Matador is the market leader and capturing more than 50% of the market share.

Though Anwar Brush Company is the oldest, it is actually very weak and almost out of the business. Tri-Star toothbrush is the third largest company in terms of market share. It is the market challenger. So, Alpha toothbrush is now at second position through doing business with making a huge compromise with quality unlike Tri-star & Matador. This niche concept of cost cutting in production and procurement by using low quality Plastics, filaments, machines and reducing production steps through unfinished tufting and final trimming of filaments. All this things ensure them a very lower cost of production and like Chinese toothbrushes

Alpha is capturing the market share using low-cost, low – quality theory. This is the reason why Tri-star has lagged behind and dropped down at third position in the market because they are not compromising with the quality.

Each and every company is actually charging almost the same price from the customer. They know that the market is very competitive and they are trying to put a reasonable price to keep up the pace with other competitors. Bottom line is at present scenario if Tri-star has to become a market leader again, it must has to fight with improving its supply chain strategy, planning and operation activities.

Competitors current machineries, labor, portfolio, turnover and market share are given below for better understanding of the insight of these market leading companies.

Nature / Description of the job:

Getting an internship opportunity in an organization like Tri-Star Toothbrush and Co. was a great advantage for me. I had the opportunity in the production department and marketing department under the supervision of Mr. Fayez Uddin Ahmed. Tri-Star is a medium sized organization which produces toothbrush in its factory. The main task of the production department is to monitoring and maintaining supply chain activities.

And the main task of marketing is to distribute those products all over the country, keep communication with area managers and sales representative, find out new market for the existing product, convey informal research through distributors on the demand of the costumers’ and let the manufacturing unit know about the production target. Though there was a separate finance and accounts department in the organization, the marketing department is the main responsible unit to keep sales and financial data and to support Accounts manager to prepare budget forecast.

As an intern I was not given so many tasks with huge responsibility. Each and every day sales data was coming to the head office in Dhaka. I have to collect those data and to document it by area and date. I have to report back to the Marketing Manger as well as the finance manger about the sales figure and amount. I also have to check the finished goods when they were about to be delivered from the depot to regional office. I have to collect the letters from the regional offices mentioning the demand of finished goods from the main depot.

Sometimes I had to visit some of the regional offices inside and outside Dhaka city. I went to those offices as a representative of our marketing manager to collect necessary documents and collect data about the local market. I was involved in several activities in that organization which was very much exciting and very good learning experiences.

SWOT analysis

Strength

- Customized product for B2B

- Strong distribution channel

- Brand awareness

- Achived experience curve and economies of scale

Weakness

- Struggling to build brand equity and brand loyalty

- Limited promotional activities due to budget constraints

- Limited CSR activities

Opportunity

- Industry expansion possibilities

- Building a loyal customer base

- Try to achieve horizontal diversificationa and vertical integration

Threats

- Slump in the economy restricting customers spending

- Political instability e.g. Strikes

- Established MNCs realizing the demand of untapped tooth brush market

Porter’s Five Forces

The 5 forces that affect a business are bargaining power of customers, bargaining power of suppliers, threat of substitutes, threats of new entrants and rivalry as shown in the figure below.

The different forces influence the activities of the business in different ways and they are:

Bargaining power of customers: The bargaining power of the customers is medium because customers would always have an opinion about the price of the product. Then again this business would provide them quality product so, customers would not have too much of an upper hand for bargaining.

Bargaining power of suppliers: Tristar would be highly dependent on the supplies of the raw materials. The suppliers would have high bargaining power because they would be well aware of the fact that the business is heavily dependent on them for both economies of scale and quality.

Threat of substitutes: The threat of substitutes is high for this business because this business is offering toothbrush and definitely customers can find substitutes of it from any other competitors. Moreover, this business is mainly emphasizing on quality so it is not compromising with the price. So it is possible that some customers are ready to shift to the cheap and compromised quality toothbrush.

Threat of new entrants: This is an untapped and profitable business and this would definitely lure other businesspeople and MNCs to attempt for this business. This means that there are high chances for new entrants to enter into the business.

Rivalry: There are two major competitors in the toothbrush industry already so, the threat from competitors is also high. The competitors include Matador and Alpha etc. They would surely give tough competition to this business

The analysis above shows that the bargaining power of the suppliers, threat of substitutes, rivalry and threat of new entrants is high. If the business wants to survive and make profit in the long-run, then, Tristar would surely have to maintain a competitive edge and a very strong image among its current and potential customers.

All in all Tristar has to get loyal customers through excellent quality toothbrush with attractive packaging and design also a certain level of personal touch to it so that customers can feel that they are being valued properly by Tristar Toothbrush & Co.

Specific Responsibilities of the Job

- Monitoring Supply Chain of production unit.

- Collect the sales report from area manager and sales representative.

- Document the data regarding sales and storage

- Notify the manager about any misleading information the documents

- Observe the transportation of finished goods from storage to regional office

- Visit regional offices to perform market research

Learning experience

As a BBA student I had to perform an internship in a business organization. I did my internship in Tri-Star Toothbrush and Co. That was my first experience of working in professional business environment. I was very much nervous before joining in that organization. But surprisingly I found out that none of the task is that much hard.

Everything was in proper order. The most important thing is to adjust with the professional work environment.

While working in that organization the most important thing I found that interpersonal communication is the most important to work in office environment. We need to communicate with different types of people from different social and cultural background. It is not easy to blend in a corporate environment so quickly. Positive attitude towards the job and responsibilities is also important. In our academic life I don’t need to take any responsibility accept my study. The only gainer or loser of my performance was me. But in an office environment where each and every activity is connected with each other, one’s performance affects the whole organization. In our personal we don’t need to care about others but in an office environment we consider everyone’s situation before taking a decision.

Hard working is the key to any success. I had to work hard in my academic career. But working in professional environment is even harder. Suddenly starting an 8-hour day job is not easy. I needed to develop a strong mental attitude for the successful performance in my internship.

Endurance is also important. Working in corporate environment can be exhaustive. We have to work with our superiors and subordinates. Not all times our performance is appreciated and sometime it is control the subordinates. But everybody must take patient approach to handle those kinds of situation.

Working three months as an intern in an organization was a very important experience for me. I believe it would help me to prepare to take the challenge of the real world.

Critical observation and Recommendation

As an internee of the company, I worked with them for three months and I look over various activity and operation of the company. As a manufacturing organization it operates its activities in a planned way. I found various things of the company like,

Tri-star Toothbrush and Co. starts its office early in the morning but it takes time to start the manufacturing unit. After opening the office at 10am everyday it opens it factory and the factory starts around 11am. Within this one hour they can produce around 3000 units of products. So I think the factory should be started its operation early so they can catch up with the office hour of the organization.

Marketing and finance department doesn’t have a direct communication with the factory workers. They only communicate with the factory manager. Sometimes information might get manipulated. May be the marketing manager wants a particular product for a particular area but the production unit is manufacturing something else. I think a direct communication between factory unit and other departments will be very productive for the company.

Most of the labors and workers in the factory are not educated. They have firsthand knowledge about the work they are performing. But sometimes it is really hard to make them understand about some management issues. If the management of Tri-Star hires labors and workers having a basic level of education, then it would be lot easier to maintain a professional culture inside the organization.

Recommendation

- They can increase promotional activities such as Billboard, newspaper, magazine and use some other media like radio. So they can get attraction and could be able to increase the number of customers. They can also go for opening a web site so that customer can get information about their product and buyers can also contract with them easily. They can also go for online advertisement like face book. We think by these ways they could able to increase their sales volume and revenue.

- They can increase their distribution channel in other areas so that they can capture more market share and fulfill their vision of becoming market leader. Tri-Star has covered almost all the areas of the country. But they are unable to supply the enough amount of product to fulfill the market demand. So it can set up factories in some other areas of the country. This will eventually help them to cut down supply chain cost.

- They have no specific R&D department for their factory. They do not perform any market research before launching any new product. If product is not accepted by target customer they might face a huge loss.

- If they don’t go for gas based power supply system, they should use one more generator for back up of the existing generator. As they have only one generator, sometimes due to technical problem in the generator they need to stop their operation.

- As they go for manual production, it takes a huge the time complete the production cycle so the quality of the product can’t be maintained always. It would be better if they convert their production process in automated manner.

- They should be more conscious about their safety. Because they have not any safety measures for workers, employees and even for factory. They only have insurance for the warehouse. So we think they can go for insurance facility for their factory and employees as well. Moreover they must have at least a few number of extinguisher facility if fire takes place in factory.

- They have no particular training program for their employees and worker. So that sometimes the unskilled worker make mistake in production process and increase wastage of raw material. Moreover the wage structure is not very popular in the factory. For that reason when worker get skilled they quit their job. For this high turnover Tri-star needs to recruit quite a few times in the year which needs time and resources as well.

Conclusion

Tri-star toothbrush & Co is one of the emerging companies in the toothbrush industry in Bangladesh. Though they are now market challenger in this industry, they have huge opportunity to become market leader within next few years. For example they have recently introduced “Doremon” branded tooth brush for children, and it is expected to grab a huge market share. Now they produce three thousands units of brushes with 20 plus modern machine in every hour and in future they are thinking that they will expand their operation by introducing more modern technology like their competitor. Throughout out their 136 distributors, they reached their product to end users around all over the Bangladesh. They have good relation with their competitors which may help them to retain their current market share. As they target mostly on rural area so they have probability to get competitive advantage over competitors. In future they want to introduce more differentiated product line by focusing on customer group by introducing popular and innovative brands. They also want to introduce more quality brush like foreign established brands (Oral-B, Colgate) in near future. They are more committed to ensure and maintain quality which helps to create trusts among consumers. Therefore if the production facile it is maintained properly they will be able to reduce cost and to reach high profit and ultimately become market leader by introducing innovative product.