The Washoe process, a variation of pan amalgamation, was developed in the 1860s by Almarin B. Paul and others, to work the ore from the Comstock Lode in Nevada, United States. It is a process of treating silver ores by grinding in pans or tubs with the addition of mercury and sometimes of chemicals (as blue vitriol and salt). The Washoe process of amalgamation was developed in the 1860s. They used iron tanks with mechanical agitators. In the Washoe Process, the improvement to the process of heating the ore during extraction in an iron pan increased the recovery and decreased the processing time. The iron from the pan acted as the reducing agent for the silver: 2AgCl + Fe = 2Ag + FeCl2

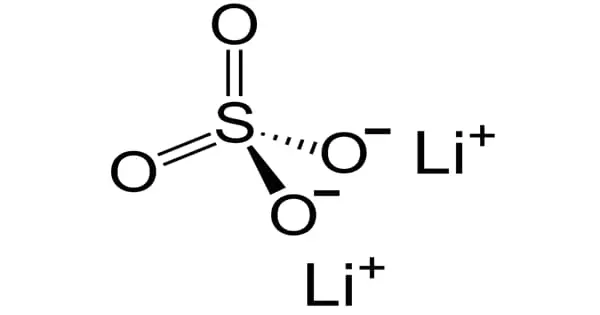

The Washoe process was more efficient, and Raymond estimated that Washoe. The Washoe process, a variation of pan amalgamation, was developed in the 1860s by Almarin B. Paul and others, to work the ore from the Comstock Lode. In the Washoe process, the copper pans were replaced by iron tanks with mechanical agitators. Ore processing technologies extract economically valuable minerals and metals. Other amalgamation processes were later developed, importantly the pan amalgamation process, and its variant, the Washoe process. It is the process of treating silver ores by grinding in pans or tubs with the addition of mercury, and sometimes of chemicals such as blue vitriol and salt. Each tank (“pan”) was circular and commonly held 1,200 to 1,500 pounds of ore that had been crushed to sand size. The drive for this reaction is nearly 0.6 volts greater than the drive for the reaction for reducing silver using copper, so this reaction is highly favored. Water was added to make a pulp, and 60 to 70 pounds of mercury, along with one-half to three pounds each of salt (sodium chloride) and bluestone (copper(II) sulfate) were also added.

A circular iron plate called a muller was mounted on a vertical shaft and lowered into the pan and was rotated to provide both agitation and additional grinding. In addition, heating the reaction mixture helped the formation of the amalgam of silver with mercury. The heat was delivered to the pans by steam pipes. In this reaction, the mercury was not changed into mercurous chloride (calomel), so mercury was not used up in the process. The iron filings worn from the muller and pan proved to be an essential ingredient in the process. The iron pans and iron mixers (mullers) would be consumed in the process, but these could be replaced readily.