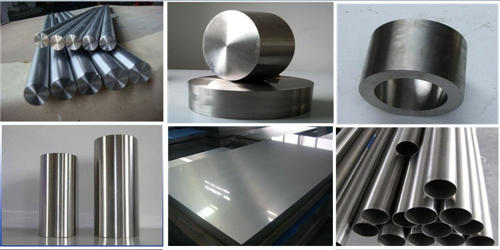

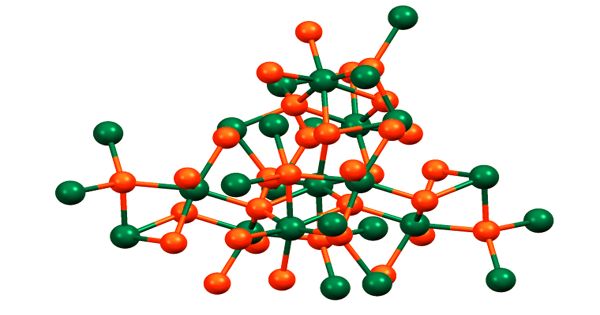

Titanium is considered to be one of the strongest metals. Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. It retains the same strength and corrosion resistance but takes on the greater flexibility and malleability of the metal it is combined with. Such alloys have very high tensile strength and toughness (even at extreme temperatures). These may be susceptible to solid-metal embrittlement when in contact with cadmium. They are light in weight, have extraordinary corrosion resistance, and the ability to withstand extreme temperatures. Titanium alloys typically contain traces of aluminum, molybdenum, vanadium, niobium, tantalum, zirconium, manganese, iron, chromium, cobalt, nickel, and copper.

Titanium alloys, therefore, have more applications than pure titanium. Although “commercially pure” titanium has acceptable mechanical properties and has been used for orthopedic and dental implants, for most applications titanium is alloyed with small amounts of aluminum and vanadium, typically 6% and 4% respectively, by weight. They are applied as biomedical materials mainly in hard tissue replacement, which requires a modulus similar to human bone and high fatigue strength. This mixture has a solid solubility which varies dramatically with temperature, allowing it to undergo precipitation strengthening. The novel aspects of application potential for titanium alloys are as a result of their unique properties such as high corrosion resistance, low elastic modulus, and high hardness. This heat treatment process is carried out after the alloy has been worked into its final shape but before it is put to use, allowing much easier fabrication of a high-strength product.

The attributes of titanium alloys of prime importance to the design engineer are:

- Outstanding corrosion resistance

- Excellent erosion resistance

- High heat transfer capability

- Superior strength-to-weight ratios

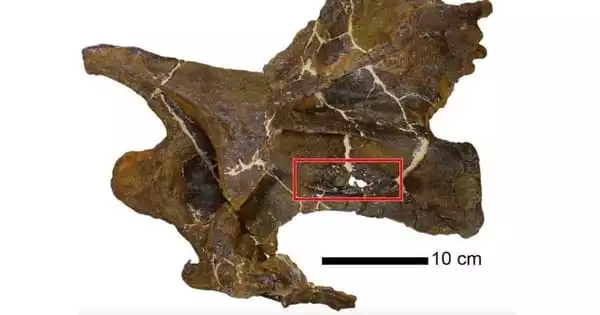

Titanium alloys were developed in the mid-1940s for the aviation industry and were first used in orthopedics around the same time. They are advanced structural materials for numerous key engineering applications in medicine (implants), aerospace, marine structures, and many other areas.

Uses

Titanium alloys are widely used for the manufacture of orthopedic implants in total hip arthroplasty both for cemented and cementless prostheses. Its strength, heat, water, and salt resistance, and its lightweight make it the ideal metal for a variety of applications. They have various applications in biomedicine, aerospace, marine, energy, and chemical industries. These applications range from jewelry and dental implants to airplanes and ships. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars, and some premium sports equipment and consumer electronics.