Three-dimensional (3D) microfabrication refers to manufacturing techniques that use material layering to create a three-dimensional structure at a microscopic scale. It is the process of using microfabrication techniques to create three-dimensional structures or devices on a small scale. These structures, which are typically on the micrometer scale, are widely used in microelectronics and microelectromechanical systems. It entails the precise and controlled manipulation of materials at the micro- and nanoscales in order to build complex three-dimensional objects.

Traditional microfabrication techniques, such as photolithography and etching, are primarily used on flat substrates for two-dimensional (2D) patterning. Advances in additive manufacturing, lithography, and other fabrication techniques, on the other hand, have enabled the development of 3D microfabrication methods.

There are several approaches to 3D microfabrication:

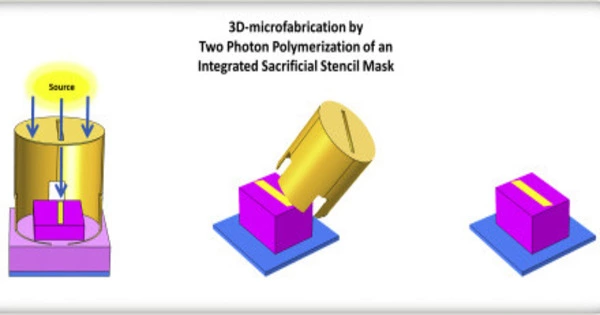

- Additive Manufacturing: Building 3D structures layer by layer with materials such as polymers, metals, ceramics, or composites is the goal of this technique. To create complex structures with high resolution, additive manufacturing techniques such as two-photon polymerization, direct laser writing, and stereolithography are used.

- Multi-layer Stacking: Multiple 2D layers are fabricated separately and then stacked or bonded together to form a 3D structure in this approach. Traditional microfabrication techniques such as photolithography and etching, as well as other methods such as printing or laser machining, can be used to create each layer.

- Microscale Assembly: In microscale assembly, individual micro- or nanoscale components are fabricated separately and then assembled to form the final 3D structure. This can involve techniques like pick-and-place assembly, self-assembly, or template-guided assembly.

- Microscale Sculpting: Microscale sculpting involves selectively removing material from a bulk substrate to create the desired 3D structure. Techniques like focused ion beam (FIB) milling or laser ablation can be used to remove material with high precision.

Application

Microelectromechanical systems (MEMS), microfluidics, biomedical devices, optical components, sensors, and other areas benefit from 3D microfabrication. These techniques enable the creation of intricate and functional structures at the microscale, paving the way for advancements in a variety of fields that rely on miniaturization and precise control of three-dimensional features.