Researchers at QUT have created a novel method for creating protein-based molecular ON-OFF switches that can be employed in a wide range of biotechnological, medicinal, and bioengineering applications.

The study team showed that this innovative method enables them to design and construct quicker and more precise diagnostic tests for identifying diseases, monitoring water quality, and identifying contaminants in the environment.

Professor Kirill Alexandrov, of the QUT School of Biology and Environmental Science, lead scientist on the CSIRO-QUT Synthetic Biology Alliance and a researcher with the ARC Centre of Excellence in Synthetic Biology, said that “the new technique published in the scientific journal Nature Nanotechnology demonstrated that protein switches could be engineered in a predictable way.”

Professor Alexandrov said protein-sensing systems were utilized in the already available ‘point of care’ diagnostic tests that gave quick answers, such as blood glucose, pregnancy, and COVID test kits, to identify the presence of sugar, pregnancy hormones, and COVID proteins.

“These, however, represent only a tiny fraction of what is needed in patient-focused healthcare model,” Professor Alexandrov said.

“However, developing new sensing systems is a challenging and time-consuming trial-and-error process.”

“The new ‘protein nano-switch’ method can massively accelerate development of similar diagnostics by decreasing the time and increasing the success rate. It uses proteins modified to behave like ON/OFF switches in response to specific targets.”

“The advantage of our approach is that the system is modular, similar to building with Lego bricks, so you can replace parts easily to target something else another drug or a medical biomarker, for example.”

One is to develop computer models that allow us to design and build the switches even more rapidly and precisely. The other is to demonstrate the scale and potential of the technology by building many switches for different diagnostic applications.

Dr. Zhong Guo

Professor Alexandrov said with a wide range of potential applications, including diagnostics in human and animal health, testing kits for water contamination, and detecting rare earth metals in samples to guide mining operations, the technology presented the option of developing numerous distinct diagnostic and analytical tests.

The multidisciplinary research team included scientists from QUT and the ARC Centre of Excellence in Synthetic Biology, consisting of lead researcher Professor Kirill Alexandrov, Dr. Zhong Guo, Cagla Ergun Ayva, Patricia Walden and Adjunct Professor Claudia Vickers.

The QUT team collaborated with leading electrochemists Evgeny Katz and Oleh Smutok from Clarkson University, in New York, and chemical pathologist Dr. Jacobus Ungerer from Queensland Health.

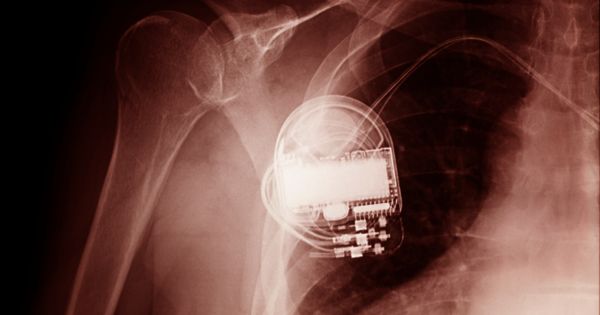

The team employed a cancer chemotherapy treatment that is harmful and necessitates continuous measurement to assure patient welfare to showcase the technology.

“Too little of the drug won’t kill the cancer, but too much could kill the patient,” Professor Alexandrov said.

The sensor the team designed for the drug uses a colour change to identify and quantify the drug.

The sensor would then undergo testing in Queensland Health laboratories in order to be cleared for use in a clinical setting, according to Professor Alexandrov.

Professor Kirill Alexandrov.

“It’s really exciting, because it’s the first time an artificially designed protein biosensor may be actually suitable for a real-life diagnostic application,” Professor Alexandrov said.

Dr. Ungerer said the protein-engineering technology developed by the research team provided a novel means to create laboratory tests.

“This has the potential to improve and expand laboratory testing, which will result in substantial health and economic benefits,” Dr. Ungerer said.

Dr. Guo said these advancements were made possible by an international and interdisciplinary team and excellent teamwork.

The following phase, according to Professor Alexandrov, was to standardize and scale this methodology before beginning to develop more complex sub-systems. There are two potential directions for the work, he claimed.

“One is to develop computer models that allow us to design and build the switches even more rapidly and precisely,” he said. “The other is to demonstrate the scale and potential of the technology by building many switches for different diagnostic applications.”

In the future, the team may utilize the same concepts to create components that didn’t already exist and would be created from scratch, according to Professor Alexandrov, who noted that the team was now altering proteins that already existed.

“The new technique provides scientists unprecedented control over construction of protein-based sensing systems,” he said.