Surface metrology is a subfield of metrology that measures small-scale features on surfaces. It is the scientific investigation and measurement of surface qualities and properties. It is a multidisciplinary field that includes many approaches and methodologies for quantifying and assessing surface aspects such as topography, roughness, texture, and other surface features of objects or materials.

The criteria most usually connected with the field are surface primary form, surface fractality, and surface finish (including surface roughness). It is critical in many industries and scientific disciplines, including as manufacturing, engineering, material science, and quality control, where a product’s surface finish and quality can have a substantial impact on its performance and usefulness. It is useful in many fields and is best known for the machining of precision components and assemblies with mating surfaces or that must work under high internal pressures.

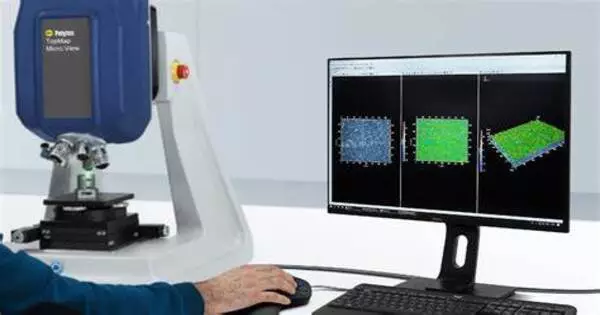

There are two methods for measuring surface finish: touch and non-contact. Profilometers are equipment that measure the surface by dragging a measurement stylus across it. Interferometry, digital holography, confocal microscopy, focus variation, structured light, electrical capacitance, electron microscopy, photogrammetry, and non-contact profilometers are examples of non-contact technologies.

Key aspects of surface metrology include:

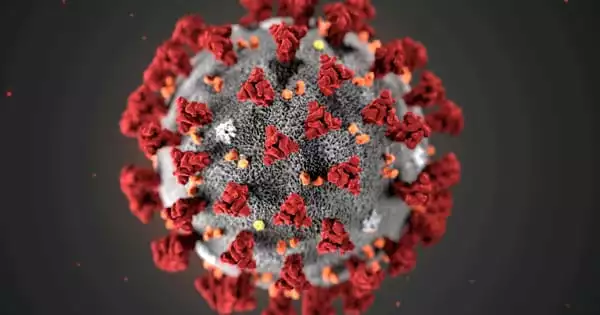

- Surface Topography: This refers to the three-dimensional (3D) shape or form of a surface. Surface topography is typically described using parameters such as height, spacing, and distribution of surface features like peaks, valleys, and asperities.

- Surface Roughness: Surface roughness quantifies the irregularities, deviations, and fine-scale features of a surface. It is often characterized by parameters such as Ra (average roughness), Rz (maximum peak-to-valley height), and others.

- Surface Texture: Surface texture encompasses the repetitive or patterned deviations from a perfect surface. It includes parameters like waviness, lay, and bearing ratio, which describe the texture’s overall characteristics.

- Surface Finish: The total quality of a surface after manufacturing procedures such as machining, grinding, polishing, or coating is represented by surface finish. It is normally graded based on its roughness and texture.

Surface metrology is critical in maintaining the quality and performance of goods in a wide range of industries, including automotive, aerospace, electronics, and medical devices. It assists manufacturers in optimizing operations, improving product performance, and adhering to quality standards and requirements. Furthermore, surface metrology is critical in R&D to better understand and manipulate surface qualities for specific applications.