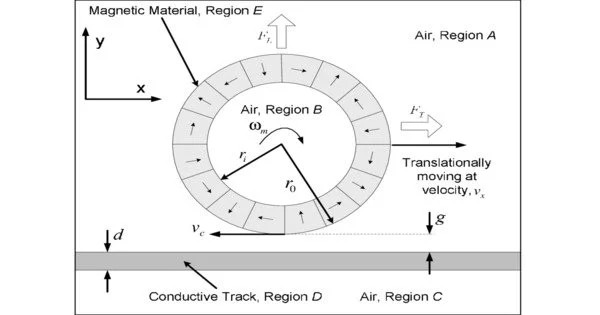

An electrodynamic wheel is a type of wheel proposed for use in the maglev train transport system’s electrodynamic levitation. This motor is used to propel the wheel and improve its functionality. Electrodynamic wheels’ specific characteristics and applications can vary depending on the context in which they are used.

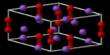

An electrodynamic wheel, unlike a conventional wheel, has a rim studded with alternating pole magnets. Magnetic fields are induced in the conductive guideway as the wheel spins at a rate that causes slip between the rim and the guideway’s surface, repelling the wheel.

An electrodynamic wheel is frequently used as a hub motor in the context of electric vehicles. Hub motors are built into the wheel, eliminating the need for a traditional drivetrain system that includes axles, differentials, and transmissions. Power can be distributed to individual wheels independently by placing the motor directly in the wheel, allowing for more precise control and potentially improving overall efficiency. Electrodynamic wheels can provide propulsion, braking, control, and lift depending on their spin.

Using 2D model

The mechanical rotation of a radially positioned permanent-magnet Halbach array above a conducting, nonmagnetic track induces eddy currents in the track that can inductively create suspension and propulsion forces simultaneously. The parameters that affect the performance of this electrodynamic wheel are studied using a 2-D steady-state finite-element method.

Examples

The Hendo hoverboard uses electrodynamic wheels to levitate itself over a conductive surface.

Benefits of electrodynamic wheels in electric vehicles include:

- Simplified design: Electrodynamic wheels eliminate the need for complex drivetrain components, reducing weight and mechanical complexity.

- Regenerative braking: The motor can act as a generator during deceleration or braking, converting kinetic energy back into electrical energy and recharging the vehicle’s battery. This regenerative braking feature can increase the overall efficiency of the vehicle.

- Torque vectoring: Individual control of each wheel’s motor allows for torque vectoring, which can improve vehicle stability, traction, and handling by distributing torque to specific wheels as needed.

- Increased interior space: With no bulky drivetrain components taking up space, the interior of the vehicle can be more efficiently utilized.

- Enhanced maneuverability: Electric motors can provide instant torque and precise control, allowing for better maneuverability in tight spaces and improved handling characteristics.