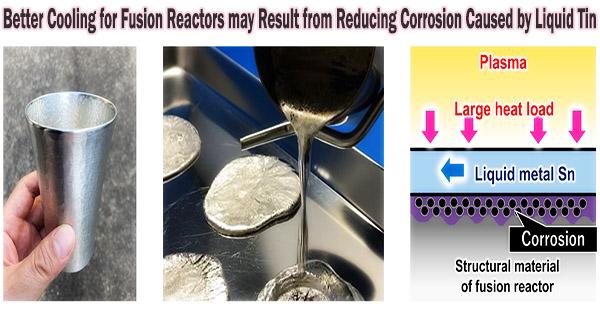

Corrosion is the degradation of materials due to their reaction with their environment. In fusion reactors, corrosion can be a significant issue because of the high temperatures and intense radiation that these devices generate.

The chemical compatibility between decreased activation ferritic martensitic, a potential structural material for fusion reactors, and high temperature liquid metal tin (Sn), has been clarified by researchers at Tokyo Institute of Technology and the National Institute for Fusion Science. The creation of a liquid metal tin divertor, an enhanced heat-removal element for fusion reactors, has been made possible thanks to this finding.

The fusion reactors have a component called a divertor installed to keep the plasma pure. Liquid metals that can tolerate extremely high heat loads from high-temperature plasma have been in demand for divertors.

Liquid tin has been proposed as a potential solution for mitigating corrosion in fusion reactors because it has a high melting point, low vapor pressure, and low reactivity with other materials. When applied to the surfaces of materials used in fusion reactors, liquid tin can form a protective layer that reduces corrosion and improves the overall durability of these materials.

Background

Due to the fact that the fuel for fusion reactors may be derived from an endless supply of saltwater, these technologies are currently being actively explored around the globe as a type of sustainable, carbon-free energy. Also, they do not emit greenhouse gases.

In addition to the construction of the tokamak (ITER), which is being constructed through collaboration of seven of the world’s leading countries and regions (Japan, EU, United States, South Korea, China, Russia, and India), fusion development by the private sector is also accelerating.

The operating environment of a liquid tin divertor in a fusion reactor is under extremely harsh conditions in which corrosion by liquid tin and irradiation of fusion neutrons are superimposed. In this project, we are collaborating with the project team members from Oak Ridge National Laboratory in the United States to investigate the effects of radiation on the corrosion reaction dynamics of steel with liquid tin.

Masatoshi Kondo

The divertor, which gasifies contaminants in the plasma and transfers the gas to an exhaust pump, is one of the most crucial parts of these fusion reactors. Some of the structural parts of the divertor are subjected to heat loads as great as those experienced by the “space shuttle when entering the atmosphere” when a fusion reactor is operating.

A solid divertor is being developed by researchers, which involves putting a block of heat-resistant material, such tungsten, in contact with the plasma and cooling it with high-temperature, high-pressure water. Additionally, the ITER project and the experimental fusion reactors both employ this solid divertor technology.

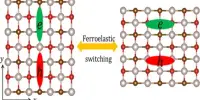

Researchers have also thought of the idea of a liquid metal divertor, which shields the divertor from plasma by coating the structural material of the divertor with a liquid metal that has good cooling performance. This novel mechanism can endure the high heat load from plasma.

Tin (Sn) is a metal that has been used in various ways in our daily lives; for example, as a material for tableware and as a component of solder. Tin has a relatively low melting point of 232°C and is suitable for use in a liquid state.

Tin’s lower vapor pressure at high temperatures than other liquid metals is another characteristic. Even when heated by plasma to a high degree and used as a coolant to cover and shield the structural material surface of the liquid metal divertor of a fusion reactor, liquid metal tin is difficult to evaporate.

Additionally, it has the benefit of decreasing the likelihood of plasma mixing with the evaporated metal. However, researchers have been troubled by the technical problem of structural materials corroding.

Research results

Kondo’s laboratory has focused on chemical coexistence with various structural and functional materials. The laboratory has given particular attention to liquid metal coolants attracting attention in the field of next-generation energy such as fusion reactors.

Tin in liquid form, which exposes the unfavorable trait of being extremely reactive at high temperatures, was the main focus of the research. They searched for materials that display corrosion resistance and clarified the corrosion mechanism of the structural components of fusion reactors.

What is high-temperature liquid metal tin and what causes its intense corrosiveness?

Reduced activation ferritic martensitic (Fe-9Cr-2W-0.1C), which is the primary candidate structural material for fusion reactors, is based on the composition of ferritic martensitic heat-resistant steel. Reduced activation ferritic martensitic uses additive elements that reduce induced radioactivity, assuming use in a neutron irradiation environment in a reactor.

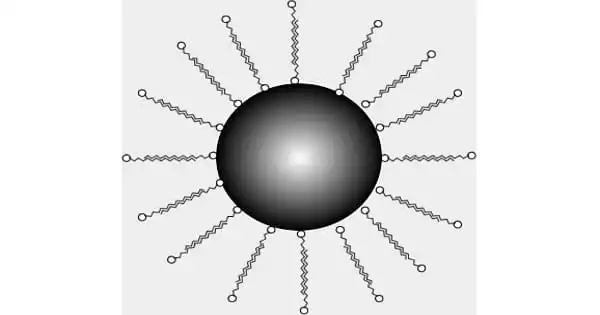

When reduced activation ferritic martensitic steel comes into contact with liquid metal tin, the incubation period before corrosion begins is very short. The researchers determined that the steel contains iron (Fe) which reacts with high-temperature tin to corrode the material while rapidly forming intermetallic compounds (FeSn2, etc.) on the tin.

Reduced-activation ferritic martensitic steel has chromium and tungsten, two substances that are resistant to tin reaction, in addition to iron. As a result, the corrosion rate of the steel is lower than that of pure iron. However, the steel corrodes and forms an intermetallic compound with a thickness of around 155 micrometers after ten days at 500°C. The thickness might reach the order of millimeters when extrapolating these figures to one year, which is a very high corrosion rate.

At 600°C, the researchers found that thinning due to corrosion became even more severe. At this point, the researchers also discovered that corrosion advances as a result of tin’s inward diffusion into the steel’s microstructure.

Associate Professor Masatoshi Kondo of Tokyo Institute of Technology, who leads the research team, gave the following explanation:

“Although liquid metal tin is an excellent coolant with a variety of properties, it has the drawback of corroding structural materials. By clarifying the corrosion mechanism, we hope to promote the use of liquid metal tin not only for fusion energy but also for solar thermal power plants.”

What materials can withstand high-temperature liquid metal tin at high temperatures?

The scientists discovered that when exposed to high-temperature liquid metal tin, structural materials made of steel and iron corrode both outside and inside while creating intermetallic compounds. This is due to the reaction between high-temperature liquid tin and iron, the primary component of steel.

As a result, the researchers hypothesized that by mixing the iron and oxygen beforehand to form an oxide prior to the reaction, it would be feasible to prevent interaction with high-temperature tin. Pursuing this theory, the researchers tested iron oxide (Fe2O3) and chromium oxide (Cr2O3) for compatibility with liquid tin at 500°C. Tin partially filtered into the pores formed following burning when submerging the iron oxide sintered material.

On the material surface, the reaction structure with tin was roughly 1 millimeter thick. Only about 1% of decreased activation ferritic steel underwent this incredibly thin reaction.

Additionally, it can be seen that the reaction structure with tin on the surface of the sintered chromium oxide material is quite thin. By first reacting with oxygen to generate an oxide, the researchers discovered that even a metal element like iron, which readily combines with tin, can be greatly repressed.

“The operating environment of a liquid tin divertor in a fusion reactor is under extremely harsh conditions in which corrosion by liquid tin and irradiation of fusion neutrons are superimposed,” explained Professor Kondo, who leads research by the Japanese team in Task 3 of the U.S.-Japan Science and Technology Cooperation Program: FRONTIER Project). “In this project, we are collaborating with the project team members from Oak Ridge National Laboratory in the United States to investigate the effects of radiation on the corrosion reaction dynamics of steel with liquid tin,” he added.

The findings mentioned in this article helped to clarify the reason for and mechanism of the corrosion of the relatively corrosive liquid metal tin. By contributing in the creation of extremely dependable cutting-edge heat-receiving equipment for fusion reactors, this research will greatly contribute to the realization of a carbon-neutral society.

Additionally, liquid tin has good thermal conductivity, which means it can help to improve the cooling of fusion reactor components. This could be especially important in situations where conventional cooling methods are not sufficient, such as during a plasma disruption event, when temperatures can spike rapidly.