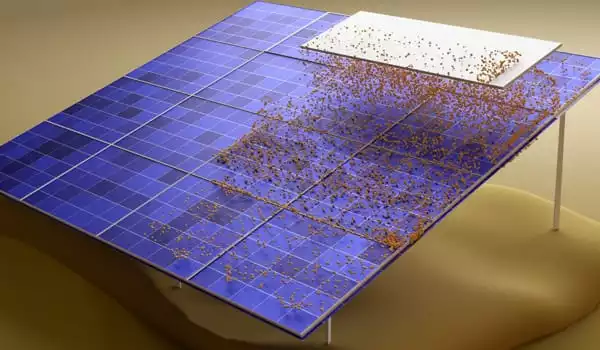

The accumulation of dust on solar panels is a serious issue, yet washing the panels requires a large amount of water. Engineers have now created a waterless cleaning method for removing dust from solar installations in water-stressed areas, increasing overall efficiency.

Solar power is predicted to account for 10% of worldwide power output by 2030, with much of it concentrated in desert areas where sunshine is abundant. However, dust collection on solar panels or mirrors is already a serious concern (it can diminish the output of photovoltaic panels by up to 30% in just one month), thus regular cleaning is required for such systems.

Cleaning solar panels, on the other hand, is expected to use roughly 10 billion gallons of water every year – enough to give drinking water to up to 2 million people. Attempts at waterless cleaning are labor demanding and often result in irreparable surface scratching, which affects efficiency. A team of MIT researchers has developed a method for mechanically cleaning solar panels or the mirrors of solar thermal plants in a waterless, no-contact system, which they claim might drastically minimize the dust problem.

Without the use of water or brushes, the novel method employs electrostatic repulsion to cause dust particles to detach and leap off the panel’s surface. A simple electrode is passed just above the surface of the solar panel to charge the dust particles, which are subsequently repelled by a charge provided to the panel itself. Using a basic electric motor and guide rails along the side of the panel, the device can be controlled automatically. The findings were published in the journal Science Advances in a report by MIT graduate student Sreedath Panat and mechanical engineering professor Kripa Varanasi.

There’s a lot of research going on with solar materials. They’re pushing the envelope, trying to gain a few percentage points here and there in terms of efficiency, and here you have something that can annihilate all of that straight immediately.

Professor Kripa Varanasi

Despite concerted efforts worldwide to develop ever more efficient solar panels, Varanasi says, “a mundane problem like dust can actually put a serious dent in the whole thing.” Lab tests conducted by Panat and Varanasi showed that the dropoff of energy output from the panels happens steeply at the very beginning of the process of dust accumulation and can easily reach 30 percent reduction after just one month without cleaning. Even a 1 percent reduction in power, for a 150-megawatt solar installation, they calculated, could result in a $200,000 loss in annual revenue. The researchers say that globally, a 3 to 4 percent reduction in power output from solar plants would amount to a loss of between $3.3 billion and $5.5 billion.

“There’s a lot of research going on with solar materials,” Varanasi says. “They’re pushing the envelope, trying to gain a few percentage points here and there in terms of efficiency, and here you have something that can annihilate all of that straight immediately.”

Many of the world’s largest solar power projects, including those in China, India, the United Arab Emirates, and the United States, are located in desert areas. The water required to clean these solar panels with pressurized water jets must be trucked in from afar, and it must be extremely pure to avoid leaving deposits on the surfaces. Dry scrubbing is occasionally done, although it is less successful at cleaning the surfaces and can produce permanent scratches, which lowers light transmission.

Water cleaning accounts for around 10% of the running costs of solar installations. According to the researchers, the novel approach might potentially cut these expenses while enhancing total power output by allowing for more frequent automatic cleanings.

“The water footprint of the solar business is mind-boggling,” Varanasi says, and it will grow as these systems expand globally. “As a result, the industry must be extremely cautious and analytical about how to make this a long-term solution.”

Other groups have attempted to build electrostatic-based solutions, but they have depended on a layer known as an electrodynamic screen, which employs interdigitated electrodes. According to Varanasi, these screens can have flaws that allow moisture enter and lead them to break. While they may be advantageous on Mars, where moisture is not an issue, he claims that even in dry regions on Earth, this can be a severe concern.

The new method they created uses simply an electrode, which can be a simple metal bar, to travel over the panel, creating an electric field that charges the dust particles as it passes. An opposite charge applied to a transparent conductive layer just a few nanometers thick deposited on the glass covering of the the solar panel then repels the particles, and by calculating the right voltage to apply, the researchers were able to find a voltage range sufficient to overcome the pull of gravity and adhesion forces, and cause the dust to lift away.

Experiments on a laboratory-scale test installation using specially manufactured laboratory samples of dust with a range of particle sizes revealed that the method works efficiently, according to Panat. The experiments revealed that humidity in the air provided a thin coating of water on the particles, which was critical to the effect working. “We conducted studies at humidity levels ranging from 5% to 95%,” Panat explains. “You can remove practically all of the particles off the surface as long as the ambient humidity is greater than 30%, but as humidity declines, it gets more difficult.”

“The good news is that when you get to 30 percent humidity, most deserts actually fall into this regime,” says Varanasi. Even those that are normally drier have higher humidity in the early morning hours, resulting in dew formation, thus the cleaning could be planned properly.

“Moreover, unlike some previous work on electrodynamic screens, which do not work at high or even moderate humidity,” Panat explains, “our device can perform at humidity as high as 95 percent indefinitely.”

At scale, each solar panel might be fitted with railings on both sides, with an electrode spanning the entire panel. A small electric motor, maybe powered by a small amount of the panel’s output, would drive a belt system to move the electrode from one end of the panel to the other, causing all the dust to fall away. The entire procedure might be mechanized or remotely controlled. Instead of moving pieces, small strips of conductive transparent material might be permanently positioned above the panel.

Such technologies have the potential to dramatically enhance the overall efficiency and reliability of solar installations by eliminating the need for trucked-in water, reducing dust buildup that can contain corrosive chemicals, and cutting overall operational expenses, according to Varanasi.