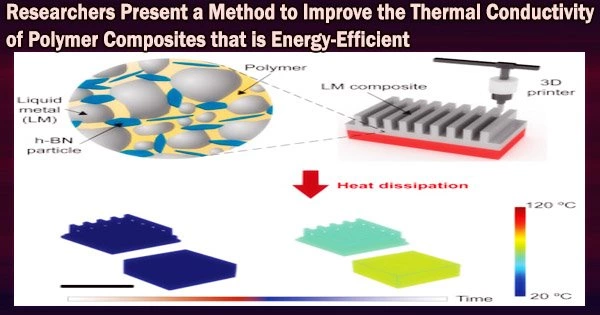

Thermally conductive polymer composites are used between a heat source and a sink in electronics to dissipate the generated heat to the surroundings due to their lightweight and flexible nature. Use of fillers with specific orientations that promote heat flow results in efficient heat dissipation.

However, the usual method of changing the orientation of the filler material needs the application of electric/magnetic fields and surface alterations, which might degrade the filler’s quality and thermal qualities.

Now, in a new study, Professor Chae Bin Kim and his team at Pusan National University, Republic of Korea, have developed an energy-efficient process to change the orientation of the filler without the need for surface modifications.

This paper was made available online on 17 October 2022 and will be published in Volume 117 of the journal Polymer Testing on 1 January 2023.

The thermophoresis, a process where a temperature gradient causes solid particles floating in a fluid media to move or spin, is used in the proposed method. The hexagonal boron nitride (h-BN) filler particles were suspended in a UV-curable liquid and deposited between two glass plates to create the polymer composite.

Efficient heat dissipating materials can ensure best operating conditions for the device with improved reliability, lifespan, and user’s safety.

Professor Chae Bin Kim

The filler particles rotated and realigned along the imposed temperature gradient after a temperature gradient was applied along the film thickness. The composite was photocured after reaching the necessary orientations, creating a solid composite with set filler orientations that create a heat transmission channel.

“To our best knowledge, the current study is the first experimental demonstration of controlling anisotropic filler orientation using thermophoresis,” says Professor Kim.

Phones, computers, and even batteries use thermally conductive polymer composites, such as thermal paste. The suggested technology has the potential to decrease the energy cost of producing thermally conductive polymer composites, taking into account the expanding production of electronics and the anticipated switch to electric vehicles.

Highly effective thermally conductive polymer composites can also be created without the requirement for surface alterations to increase heat dissipation and prolong the lifespan of electronics.

“Efficient heat dissipating materials can ensure best operating conditions for the device with improved reliability, lifespan, and user’s safety,” says Professor Kim.

Fillers are used to modify a composite’s optical, electrical, and mechanical properties in addition to enhancing heat conductivity.

The suggested method can be used to adjust the properties of a variety of polymer composites without lowering their quality since it provides a way to reposition the filler without altering the surface.