Cathodic modification refers to improvements or alterations made to a metal structure’s cathodic protection system in order to increase its efficacy in preventing corrosion. It is a technique for controlling corrosion of a metal surface by using it as the cathode of an electrochemical cell.

Cathodic modification in chemistry is the delay of anodic reactions caused by an increase in an alloy’s ability to be passivated by the insertion of an active cathode into the alloy, such as the alloying of stainless steel and titanium with platinum group metals (1). This is one method of producing corrosion-resistant alloys and increasing their resistance to electrochemical assault.

Here are some common methods of cathodic modification:

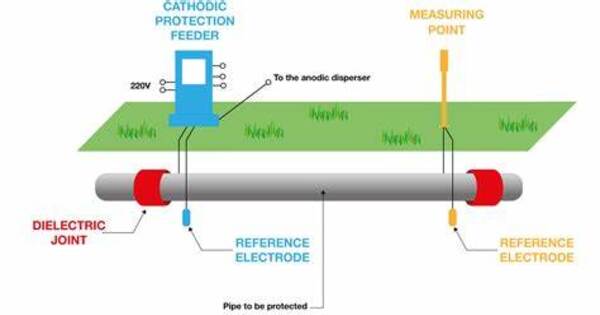

- Impressed Current Cathodic Protection (ICCP): This approach uses an external power source to provide a direct current to the metal structure, which serves as the cathode. This strategy is commonly employed when sacrificial anodes are neither viable or effective.

- Sacrificial Anode Replacement: Sacrificial anodes can deplete with time and may need to be replaced or augmented with new anodes in order to provide efficient cathodic protection.

- Adjustment of Electrical Potential: The electrical potential of the metal structure can be changed to keep it within the range required for successful cathodic protection. This could include changing the output of an ICCP system or replacing existing anodes with ones with a higher or lower potential.

- Monitoring and Maintenance: Regular monitoring of the cathodic protection system is essential to identify any issues or deficiencies that may require modification. Maintenance activities may include cleaning, testing, and replacing components as needed.

- Optimization of Anode Placement: The placement of sacrificial anodes or impressed current anodes can be optimized to ensure uniform protection across the entire surface of the metal structure.

Integration with Other Corrosion Control Methods

Cathodic protection can be combined with other corrosion control technologies, such as coatings or inhibitors, to give even greater corrosion resistance.

When considering cathodic modification, engage with corrosion engineers or specialists to ensure that the changes are appropriate and effective for the specific application and environment. The cathodic protection system must be properly designed, installed, and maintained to ensure its long-term efficiency in preventing corrosion and prolonging the service life of metal structures.