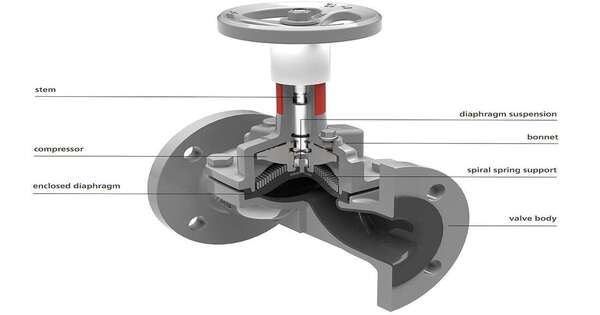

Diaphragm valves (or membrane valves) are made up of a valve body with two or more ports, a flexible diaphragm, and a “weir or saddle” or seat where the diaphragm closes the valve. It is also known as membrane valves, which use a flexible diaphragm or membrane to regulate or control fluid flow. Depending on the intended application, the valve body could be made of plastic, metal, wood, or another material.

Structure

- Diaphragm/Membrane: This is the central component of the valve. It acts as a barrier that separates the flow path from the operating mechanism. The diaphragm can be made of various materials like rubber, PTFE (Teflon), or other elastomers.

- Valve Body: The body of the valve houses the diaphragm and provides the inlet and outlet ports for fluid flow. It can be made from materials like PVC, CPVC, cast iron, stainless steel, or other corrosion-resistant materials.

- Compressor or Actuator: This is used to compress or depress the diaphragm, thereby controlling the flow of fluid through the valve.

Categories

Diaphragm valves are classified into two types: those that seal over a “weir” (saddle) and those that seal over a seat, sometimes known as “full bore or straight-through” valves. Straight-through diaphragm valves are typically utilized in on-off applications, whereas weir-type diaphragm valves are employed for control or throttling. Diaphragm valves are typically two-port (2/2-way diaphragm valves), but they can also have three ports (3/2-way diaphragm valves, also known as T-valves) or more (so-called block-valves). When more than three ports are present, they usually require more than one diaphragm seat; however, unique dual actuators can handle more ports with a single membrane.

Working Principle

- Open Position: When the valve is in the open position, the diaphragm is lifted or pushed away from the valve seat, allowing fluid to flow through the valve.

- Closed Position: In the closed position, the diaphragm seals against the valve seat, preventing fluid flow.

Advantages

- Bubble-Tight Seal: The diaphragm provides a tight seal, making these valves suitable for applications where leak-tight shut-off is required.

- Corrosion Resistance: Diaphragm valves are available in materials that offer excellent resistance to corrosion, making them suitable for handling corrosive fluids.

- Linear Flow Characteristics: Diaphragm valves generally offer linear flow characteristics, which means the flow rate is directly proportional to the valve opening.

- Biocompatibility: Some materials used in diaphragms are biocompatible, making them suitable for use in pharmaceutical and biotech applications.

Applications

- Water Treatment: Used for controlling the flow of water and wastewater in treatment plants.

- Chemical Processing: Suitable for handling various chemicals and corrosive fluids in chemical plants.

- Pharmaceuticals: Used in pharmaceutical manufacturing processes where sanitary conditions are required.

- Food and Beverage: Used for controlling the flow of food-grade liquids in the food and beverage industry.

- Mining and Slurry Handling: Suitable for handling abrasive slurries and mining applications.