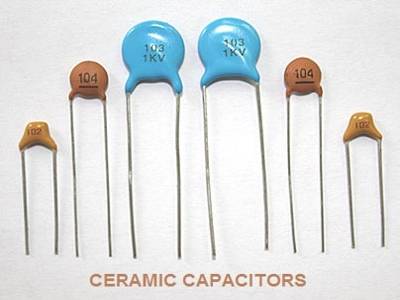

Ceramic capacitors are one of the most widely used forms of capacitor used in electronics equipment these days. is a fixed-value capacitor in which ceramic material acts as the dielectric.

Ceramic capacitors have also been used for many years, being found in valve or tube circuits dating from the 1930s. Ceramics were one of the first materials to be used in the production of capacitors, as it was a known insulator.

Today these capacitors are available in a variety of formats ranging from leaded components to surface mount technology, SMT varieties. As leaded versions disc ceramic capacitors are widely available, and as SMT devices, multilayer ceramic capacitors or MLCCs are available in all the common formats. As such these ceramic capacitors are used in virtually every type of electronics equipment.

The actual performance of the ceramic capacitors is highly dependent upon the dielectric used. Using modern dielectrics, very high values are available, but it is also necessary to check parameters such as the temperature coefficient and tolerance. Different levels of performance are often governed by the dielectric used, and therefore it is necessary to choose the type of dielectric in these capacitors.

Ceramic capacitors range in value from figures as low as a few picofarads to around 0.1 microfarads. In view of the wide range and suitability for RF applications, they are used for coupling and decoupling applications in particular. Here they are by far the most commonly used type is cheap and reliable and the loss factor is particularly low although this is dependent on the exact dielectric in use.

Ceramic capacitor basics

Ceramic capacitors are the workhorses of the capacitor world these days. They are used in millions as a result of a combination of their cost and performance. There is a wide variety of dielectrics that can be used as described below, but as the name of the ceramic capacitor suggests, they are all ceramic in nature.

In order to ensure that sufficient levels of capacitance can be obtained within a single capacitor package, ceramic capacitors, like types of the capacitor have multiple layers. This increases the level of capacitance to enable the required values of capacitance to be achieved.

These are available now in three main types although other styles are available:

- Leaded disc ceramic capacitors through hole mounting which are resin coated

- Surface mount multilayer ceramic capacitors

- Specialist microwave bare leadless disc capacitors that are designed to sit in a slot in the PCB and are soldered in place

Although it is possible to obtain other types of ceramic capacitor, these are the main types that can be found today. Of these, the surface mount variety is used in the greatest quantities by far because of the manufacturing methods used these days for electronic equipment.

Information Source: