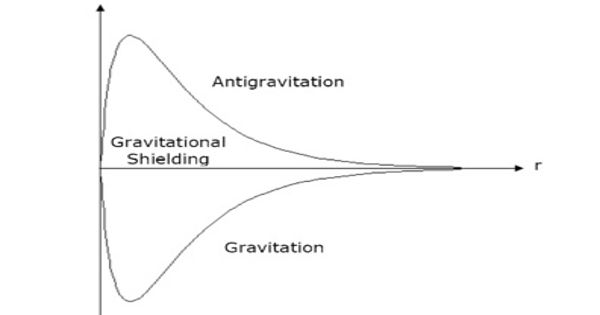

An electret is a dielectric material that has a quasi-permanent electric charge or dipole polarisation. It is a type of material that exhibits a quasi-permanent electric charge. An electret generates internal and external electric fields, and is the electrostatic equivalent of a permanent magnet. It is similar to a permanent magnet, but instead of having a permanent magnetic field, an electret has a permanent electric field. The term “electret” is a combination of “electricity” and “magnet.”

Although Oliver Heaviside coined this term in 1885, materials with electret properties were already known to science and had been studied since the early 1700s. One particular example is the electrophorus, a device consisting of a slab with electret properties and a separate metal plate. The electrophorus was originally invented by Johan Carl Wilcke in Sweden and again by Alessandro Volta in Italy.

Electrets are typically made by a process called polarization, which involves aligning the dipoles in a dielectric material and then freezing them in place. This process creates a fixed electric charge imbalance within the material. The electret retains this charge for a long time, often for years or even decades, without requiring an external power source.

The name derives from “electron” and “magnet”; drawing analogy to the formation of a magnet by alignment of magnetic domains in a piece of iron. Historically, electrets were made by first melting a suitable dielectric material such as a polymer or wax that contains polar molecules, and then allowing it to re-solidify in a powerful electrostatic field. The polar molecules of the dielectric align themselves to the direction of the electrostatic field, producing a dipole electret with a permanent electrostatic bias. Modern electrets are usually made by embedding excess charges into a highly insulating dielectric, e.g. by means of an electron beam, corona discharge, injection from an electron gun, electric breakdown across a gap, or a dielectric barrier.

Applications

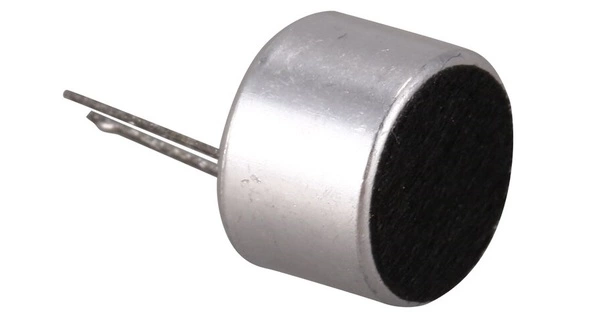

Electrets have several applications in various fields. One of the most common uses is in microphones. Electret microphones utilize a thin electret film that acts as a capacitor. Sound waves cause variations in the distance between the electret and a backplate, resulting in changes in capacitance that can be converted into electrical signals.

Electrets are also used in electrostatic speakers, which produce sound by applying an electric field to a charged electret film, causing it to vibrate and generate sound waves. Additionally, electret materials find applications in air filtration, electrostatic generators, electrostatic chucking in semiconductor manufacturing, and even in some medical devices.