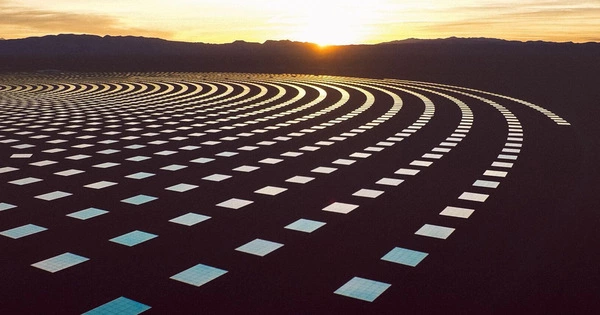

A new database contains the results of solar reflector exposure experiments conducted over the last four decades. The Solar Mirror Materials Database (SMMD) will be open to the public and will contain information from thousands of solar mirror samples from over a hundred suppliers that have been subjected to outdoor tests and laboratory environments.

The National Renewable Energy Laboratory (NREL) of the United States Department of Energy is preparing to release a database containing the results of exposure experiments on solar reflectors conducted over the past four decades. The Solar Mirror Materials Database (SMMD) will be open to the public and will contain information from thousands of solar mirror samples from over a hundred suppliers that have been subjected to outdoor tests and laboratory environments.

Typically used for concentrating solar-thermal power, these mirrors were installed and tested in Phoenix, Miami, and at NREL’s campus in Golden, Colorado. Information contained in the SMMD dates to 1980 and provides insight into how the different materials used in the mirrors degrade over time.

Concentrating solar-thermal power comes in a variety of forms. You’ve got parabolic trough, tower, Fresnel, dish, and others, but it’s all the same idea. You want to reflect solar energy and concentrate it at a single point and capture the heat.

Tucker Farrell

A new article, “Compilation of a Solar Mirror Materials Database and an Analysis of Natural and Accelerated Mirror Exposure and Degradation,” published in the Journal of Solar Energy Engineering, contains more information on the SMMD. In addition, the paper compiles decades of measurement data into a statistical analysis.

The database, according to Tucker Farrell, a research engineer at NREL and the article’s lead author, can be used to guide the development of accelerated tests, the design of solar reflectors, and the manufacturing of the devices.

“Concentrating solar-thermal power comes in a variety of forms. You’ve got parabolic trough, tower, Fresnel, dish, and others, but it’s all the same idea. You want to reflect solar energy and concentrate it at a single point and capture the heat,” Farrell said.

Farrell’s co-authors from NREL are Yue Cao, Daniel Celvi, Christa Schreiber, and Guangdong Zhu. The website containing the SMMD should be online later this year.

The SMMD houses over 2,000 samples and 100,000 measurements. Multiple samples may be tested in a single experiment under a given condition and exposure duration. For example, the researchers discovered a strong correlation between four months of accelerated testing and nine months of outdoor testing. The findings indicate that longer-duration exposures using lab equipment are required for accurate modeling. Long-term outdoor exposure experimental data is regarded as one of the SMMD’s primary advantages.

The researchers benefit from having data collected from three disparate environmental conditions. The mirrors tested in Phoenix were exposed to the lowest humidity, highest daily temperature, and largest temperature difference over a year’s time. The test site in Miami had the highest humidity but a relatively stable temperature. Golden had the lowest average temperature but a large difference in temperatures. Glass and aluminum, polymer and silver, or glass and silver are used to make the mirrors. Solar mirrors degrade or lose some of their reflectivity for a variety of reasons. Corrosion, microfractures, and pitting could be to blame, but a combination of chemical and physical changes to the reflector could also be to blame. The researchers noted that characterizing and linking the causes of the degradation to environmental issues could result in accurate models based on both the reflector and the region for which it was designed. For example, the best mirror for a dry climate with coarse sand may differ significantly from one designed for a coastal climate with high humidity and airborne salts.