The use of a Martian rock-metal composite as a building material could potentially be a great way to utilize the resources available on the planet, and 3D printing technology could make it easier to construct habitats and other structures. However, there are still many challenges to overcome before this becomes a reality.

In a 3D printing technique, a small quantity of synthetically crushed Martian rock combined with a titanium alloy produced a stronger, high-performance material that might one day be utilized on Mars to create tools or rocket parts. The components were created by Washington State University researchers using Martian regolith, a black powdery substance designed to resemble the stony, inorganic material found on the surface of the red planet. The regolith was used in amounts ranging from 5% to 100%.

While the components that included 5% Martian regolith were robust, those that contained 100% regolith were fragile and prone to cracking. However, even materials with a high Mars content could be used to create coatings that shield machinery from rust or radiation damage.

A little Martian dust appears to go a long way. In a 3D printing technique, a small quantity of synthetically crushed Martian rock combined with a titanium alloy produced a stronger, high-performance material that might one day be utilized on Mars to create tools or rocket parts.

The components were created by Washington State University researchers using Martian regolith, a black powdery substance designed to resemble the stony, inorganic material found on the surface of the red planet. The regolith was used in amounts ranging from 5% to 100%.

While the components that included 5% Martian regolith were robust, those that contained 100% regolith were fragile and prone to cracking. The corresponding author of the study that was published in the International Journal of Applied Ceramic Technology, Amit Bandyopadhyay, asserted that even materials with a high Mars content would be effective in creating coatings to shield machinery from corrosion or radiation damage.

“In space, 3D printing is something that has to happen if we want to think of a manned mission because we really cannot carry everything from here,” said Bandyopadhyay, a professor in WSU’s School of Mechanical and Materials Engineering. “And if we forgot something, we cannot come back to get it.”

Bringing materials into space can be extremely expensive. The authors, for instance, observed that it costs around $54,000 for the NASA space shuttle to launch just one kilogram (2.2 pounds) of payload into Earth orbit. Anything that can be produced in space or on Earth would reduce weight and cost, and astronauts would need a mechanism to fix anything that fails on the spot.

In space, 3D printing is something that has to happen if we want to think of a manned mission because we really cannot carry everything from here. And if we forgot something, we cannot come back to get it.

Amit Bandyopadhyay

Bandyopadhyay first demonstrated the feasibility of this idea in 2011 when his team used 3D-printing to manufacture parts from lunar regolith, simulated crushed moon rock, for NASA. Since then, the technology has been adopted by space agencies, and the International Space Station now has its own 3D printers to produce materials on-site and for experiments.

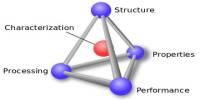

For this study, Bandyopadhyay along with graduate students Ali Afrouzian and Kellen Traxel, used a powder-based 3D printer to mix the simulated Martian rock dust with a titanium alloy, a metal often used in space exploration for its strength and heat-resistant properties.

As part of the process, a high-powered laser heated the materials to over 2,000 degrees Celsius (3,632 F). Then, the researchers were able to make various sizes and forms using the melted mixture of Martian regolith-ceramic and metal material that flowed onto a moving platform. The researchers put the material through strength and durability tests after it had cooled down.

As it cooled, the ceramic substance formed entirely of Martian rock dust broke, but as Bandyopadhyay noted, flaws are irrelevant in the context of radiation shields, so it might still produce good coatings.

However, a small amount of Martian dust, the mixture with 5% regolith, not only did not shatter or bubble, but also displayed greater qualities than the titanium alloy alone, allowing it to be used to create less weight components that could still support heavy loads.

“It gives you a better, higher strength and hardness material, so that can perform significantly better in some applications,” he said.

This study is just a start, Bandyopadhyay said, and future research may yield better composites using different metals or 3D-printing techniques.

“This establishes that it is possible, and maybe we should think in this direction because it’s not just making plastic parts which are weak but metal-ceramic composite parts which are strong and can be used for any kind of structural parts,” he said.

Additionally, transporting the necessary equipment and materials to Mars would be a major logistical challenge. Despite these challenges, the potential benefits of 3D printing on Mars are significant, and it will be interesting to see how this technology is used in the future as we continue to explore and potentially colonize the planet.