Electrohydraulic forming (EHF) is a manufacturing method that uses the energy of a high-voltage electric discharge to create metallic pieces. It is a metal-forming method in which an electric arc discharge in liquid converts electrical energy to mechanical energy and alters the shape of the workpiece. It is commonly used to shape metal sheets, tubes, and other workpieces into desired shapes.

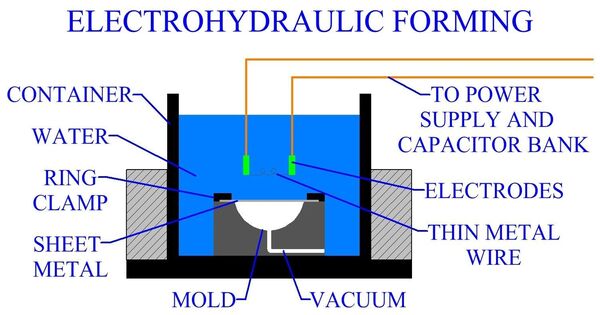

A capacitor bank sends a high-current pulse between two electrodes that are close together and submerged in a fluid (water or oil). The electric arc discharge rapidly vaporizes the surrounding fluid, resulting in a shock wave. The workpiece, which remains in touch with the fluid, transforms into an evacuated die.

Electrohydraulic forming (EHF) is a process that uses shockwaves in water to deform metal at ultra-high speeds. An electric arc is formed in water between two electrodes by discharging current from a capacitor bank. This electric arc vaporizes the surrounding water, transforming electrical energy into a powerful shockwave of mechanical energy.

Here’s how it generally works:

- Preparation: A metallic workpiece is placed between two electrodes in a fluid-filled chamber. The workpiece can be a sheet, tube, or other form of metal.

- Electric Discharge: A high-voltage electric discharge is initiated between the electrodes. This discharge creates a rapid and intense pressure wave in the fluid medium.

- Hydraulic Pressure: The pressure wave generated by the electric discharge exerts a high-pressure force on the workpiece. This force is transmitted uniformly across the surface of the workpiece, causing it to deform or form into the desired shape.

- Forming: The deformation of the workpiece occurs rapidly, often within microseconds, due to the high-pressure impulse from the electric discharge. The formed part takes the shape of the die or mold used in the process.

- Finishing: After forming, the part may undergo additional finishing processes such as trimming, cutting, or surface treatment to achieve the desired final product.

Electrohydraulic forming offers several advantages, including:

- Rapid forming speeds, make it suitable for high-volume production.

- Capability to form complex shapes with high precision.

- Reduced tool wear compared to traditional farming methods.

- Ability to work with a wide range of materials, including metals that are difficult to form using conventional methods.

However, it does have certain limitations and obstacles, such as the complexity of equipment setup, the possible safety risks connected with high-voltage discharges, and the necessity for precise control over the forming process to assure uniform results.

Overall, electrohydraulic forming is a versatile manufacturing technique with applications in a variety of industries, including automotive, aerospace, and electronics, that require complicated metal components.