Alkaline zinc batteries, one of the most popular non-rechargeable battery types used in daily life, will soon be able to be recharged thanks to a new electrode design created by a research team at The Hong Kong University of Science and Technology (HKUST). This opens up new possibilities for the use of rechargeable batteries.

In the era of smart cities and widespread digitalization, batteries are more crucial than ever. However, the vast majority of batteries on the market also known as primary batteries are not rechargeable. They are discarded after only one usage, which is an unsustainable practice that endangers the environment severely.

Alkaline zinc batteries are less expensive, more secure, and have a higher energy density than other primary battery kinds. Many common devices, like flashlights and remote controls, contain them.

Researchers from all around the world are always working to make alkaline zinc batteries rechargeable because of the benefits. However, this endeavor has been ineffective since zinc’s battery reaction is scarcely reversible.

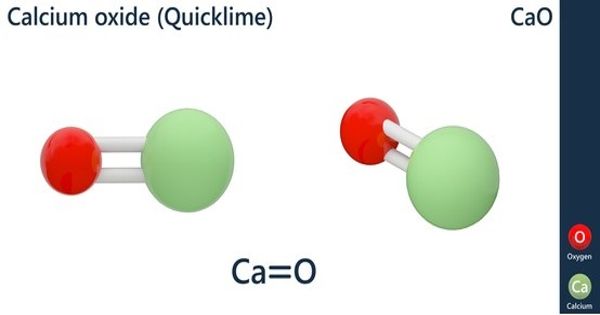

When a battery is depleted, the zinc electrode’s zinc particles get encased in a thick, uneven layer of insulating zinc oxide, losing their metal surface and electrical conductivity, which are both required for the electrode to be recharged.

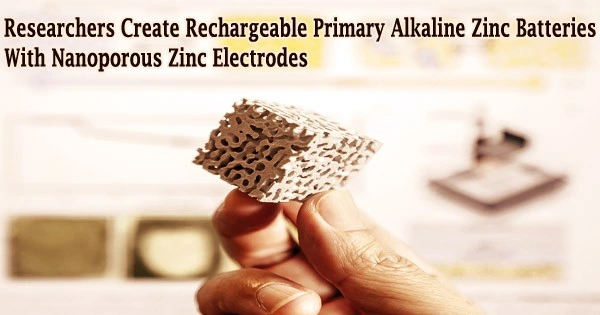

To tackle the issue, a research team led by Prof. CHEN Qing from the Department of Mechanical & Aerospace Engineering and Department of Chemistry at HKUST developed a nanoporous zinc metal electrode that is capable of stabilizing the electrochemical transition between zinc and zinc oxide, successfully turning an alkaline zinc-air coin cell, a type of primary battery usually found in hearing aids, into a rechargeable battery stable for over 80 hours.

Our work achieves so by understanding and then designing how atoms organize themselves at the liquid-solid interface that is manifested by the nanoporous structure, which has been applied to address a range of technological challenges.

Professor CHEN Qing

The group formed zinc into wavy filaments hundreds of nanometers wide, nestled in a solid that stood alone and had several pores that were similarly small. A small layer of zinc oxide forms on the zinc filaments during battery discharge, protecting the metallic network and allowing the zinc electrode to reform to its original shape.

In alkaline nickel-zinc batteries, a type of uncommon secondary zinc battery that typically offers 50–80 times of discharging and charging under conditions competitive with those of cutting-edge lithium-ion batteries, the team also tested out the nanoporous zinc electrode. The outcome showed a multiplicative growth of more than 200 times.

“The needs for batteries are diverse and difficult to be met by a single technology. Zinc batteries are finding their niche. We just need to make sure that the microstructure of the zinc electrodes can withstand hundreds, and hopefully thousands, of times of discharging and charging when getting the most energy out of the batteries,” said Prof. Chen.

“Our work achieves so by understanding and then designing how atoms organize themselves at the liquid-solid interface that is manifested by the nanoporous structure, which has been applied to address a range of technological challenges,” he explained.

Prof. Chen continued by saying that although while a few hundred cycles of charging and discharging may not seem like a lot, alkaline zinc batteries offer an advantage in terms of safety and affordability, making them perfect for commercial applications like golf carts and forklifts.

They are also appropriate for new applications, such as data center backup power, which does not necessitate frequent charging and discharging but calls for very high safety standards for the battery.

Since the start of the research in 2018, Prof. Chen’s team has collaborated with industrial partners and will continue to do so in order to commercialize the potential technologies.

The team’s research work was recently published in Nature Communications.

Led by Prof. Chen, the team included postdoctoral fellow Dr. LI Liangyu, former research assistant Anson TSANG Yung-Chak, PhD student XIAO Diwen, former postdoctoral fellow Dr. ZHU Guoyin, as well as Prof. ZHI Chunyi from the City University of Hong Kong.