Types Of Leather

Aniline leather :

From Wikipedia, the free encyclopedia

Jump to: navigation, search

Aniline leather is a type of in which high quality hides have been treated with aniline as a dye. This produces a delicate, soft, supple leather.

Typically, leather is coloured both for aesthetic reasons and to conceal blemishes. However, aniline leather is not coloured. Often the term naked leather is used. This allows the leather to breathe better, making the leather more comfortable in both hot and cold weather.

However, extra care is required when using furniture made from this leather. It is particularly susceptible to discolouration by sunlight and vulnerable to liquid spills.

Retrieved from “http://en.wikipedia.org/wiki/Aniline_leather”

Categories: Leather

Artificial leather:

From Wikipedia, the free encyclopedia

Jump to: navigation, search

Artificial leather is a fabric of finish intended to substitute for leather in fields such as upholstery, clothing and fabrics, and other uses where a leather-like finish is required but the actual material is cost-prohibitive or unsuitable.

Historic and upholstery uses:

Under the name of artificial leather, (not to be confused with the more modern Pleather) or of American leather cloth, large quantities of a material having, more or less, a leather-like surface were once used, principally for upholstery purposes, such as the covering of chairs, lining the tops of writing desks and tables, and so on.

There was considerable diversity in the preparation of such materials. A common variety consists of a web of calico coated with boiled linseed oil mixed with dryers and lampblack or other pigment. Several coats of this mixture were uniformly spread, smoothed and compressed on the cotton surface by passing it between metal rollers, and when the surface was required to possess a glossy enamel-like appearance, it received a finishing coat of copal varnish. A grained morocco surface was given to the material by passing it between suitably embossed rollers.

Preparations of this kind have a close affinity to cloth waterproofed with rubber, and to such manufactures as ordinary waxcloth. An artificial leather which was patented and proposed for use as soles for boots, etc., was composed of powdered scraps and cuttings of leather mixed with solution of guttapercha dried and compressed. In place of the guttapercha solution, oxidized linseed oil or dissolved resin could be used as the binding medium for the leather powder.

Clothing and fabric uses:

Synthetic leathers, at times made from plastics, are often used in clothing and fabrics. Artificial leather is marketed under many brands, including “leatherette,” “faux leather,” “patent leather,” “Naugahyde” and “pleather”.[1]

Plastic leather:

The term pleather (“plastic leather”) is a slang term for synthetic leather made out of plastic, a portmanteau of plastic and leather, the term can be either descriptive, or derogatory, depending upon the user (the derogatory use implies use as a substitute for genuine animal hide leather to cut costs).

Pleather is often used as an inexpensive substitute for leather. Pleather may also be preferred because it is lighter than leather. Others choose to wear synthetic leather as an alternative to real leather citing reasons of animal cruelty. [2] Pleather, being made of plastic, will not decompose as quickly.

Not all pleathers are the same. Polyurethane is washable, can be dry-cleaned and allows some air to flow through the garment.[citation needed] PVC pleather in contrast does not “breathe” and is difficult to clean. PVC cannot be dry-cleaned because the cleaning solvents can make the PVC unbearably stiff.

Bicast leather:

From Wikipedia, the free encyclopedia

Jump to: navigation, search

Bicast leather (also known as bycast leather or PU leather) is a synthetic upholstery product consisting of a thick polyurethane layer applied to a leather or reconstituted leather substrate. It is commonly found in inexpensive furniture.

Some manufacturers use the bycast treatment to process their leather, which provides a smooth, shiny finish as well as protection to the leather.

Because bicast leather is fundamentally a man-made product, some jurisdictions (such as New Zealand and the United Kingdom) have ruled that it cannot be marketed as leather.

Early registration for Wikimania 2008 is now open.

Boiled leather:

From Wikipedia, the free encyclopedia

• Ten things you may not know about Wikipedia •Boiled leather, sometimes called cuir bouilli, was a historical construction material for armour. It consists of thick leather, boiled in water (some sources hold that oil and wax were used as well, others posit the use of ammonia from fermented animal urine). The boiling causes the leather to be harder and more brittle. The boiled leather can be fashioned into lames/scales to make lamellar or scale armor. Or, because the leather remains flexible for a short time after boiling, it can be molded into larger ‘plates’.

Cuir bouilli has also been employed to bind books.

Bonded Leather:

From Wikipedia, the free encyclopedia

• Learn more about using Wikipedia for research •

Jump to: navigation, search

Bonded Leather, or “Reconstituted Leather” is not really a true leather but a man-made material composed of 80% to 100% leather fibers (often waste scraps from leather tanneries or leather workshops). It consists of collagen fibers obtained from macerated hide pieces bonded together with latex binders constructed into a fibrous mat to create a look and feel similar or sometimes identical to that of genuine leather but at a fraction of the cost. Depending on the quality a man-made pattern is usually discernible as a “grain-like” look.

Examples of products that are most commonly constructed with bonded leather are; Bibles, diaries, art books, desk accessories, hymnals, bags, belts, chairs, sofas, etc.

There are manufacturers who call their chemical treated leather bonded leather.

Chamois leather:

From Wikipedia, the free encyclopedia

Definition:

Great Britain:

The British Standard BS 6715: 1991[1] is widely considered to offer the correct definition of chamois leather. This defines chamois leather as:

- Leather made from the skin of the mountain antelope or Chamois

- Leather made from the flesh split of sheepskin or lambskin, or from sheepskin or lambskin from which the grain (the top split) has been removed by frizing, and tanned by processes involving oxidation of marine oils in the skin, using either solely such oils (full oil chamois) or first an aldehyde and then such oils (combination chamois)

United States:

In the USA the term chamois without any qualification is restricted to the flesh split of the sheep or lambskin tanned solely with oils. (US Federal Standard CS99-1970[2]).

The term is often mistakenly used to refer to cloths made from the skin of other animals (often common goat, kid or pig), or a synthetic material version, these are not considered ‘genuine chamois’.

Properties:

Tests have shown that genuine chamois leather is the least abrasive drying material for any auto surface (particularly the various Lacquers). This, coupled with its softness and super-absorbent properties, has made it a very popular product for car-cleaning and drying through out the world.

The stretchy pores of the skin, which are very close, allow it to be used in micro-filtration. Its water absorbency makes it good for other uses, such as in cycling shorts (although most modern cycling shorts now use synthetic chamois leather). It was also used in purifying mercury, which is done by passing it through the pores of the skin.[3]

Chamois has the property that when soaked with clean fuel it will not allow water to pass through its surface fibers. This property is used to filter fuel that has been stored in drums (always prone to ingress of water) or from any other doubtful source. The technique is to provide a large-mouthed funnel with a wide outlet surface that is supports a woven wire base, or grid of metal plate drilled with many holes. The lower part of the funnel is tapered to fit the receptacle or tank-filler aperture.

A suitably-sized Chamois hide is soaked in clean fuel and placed over the grid in the funnel and bought up the sides, forming a bowl, to prevent any leakage past the skin. Fuel can then be pumped into the top of the funnel by the fuel dispenser and watched for signs of water accumulation. The process can be stopped to lift out the assembly from the tank and the trapped water removed so that the job can be continued. Like this Chamois leather is used as a fuel filter by auto detailers—and aircraft refuellers, particularly of a past age where aircraft were flown into very remote areas.

Chamois leather is popular today on professional film and video camera viewfinders, as it provides comfort and absorbs sweat for camera operators who spend a long time with their eye planted on the viewfinder.

Being somewhat spongy, Chamois easily retains oil, making it good for wiping fingerprints from polished metallic surfaces such as on a firearm.

Chamois also has medical uses in orthopedics.

The true chamois leather is often counterfeited with common goat, kid or pig skin; the practice of which is a particular profession, called by the French chamoiser.[3]

Corinthian leather:

From Wikipedia, the free encyclopedia:

• Ten things you may not know about images on Wikipedia •

Jump to: navigation, search

Corinthian leather was a phrase invented for marketing use to describe the leather used in certain Chrysler luxury cars in the 1970s. The first use of this term was to describe the leather in the 1974 Chrysler Imperial, but the best known use of this term is from the advertising campaign for the 1976 Chrysler Cordoba, featuring celebrity spokesman Ricardo Montalbán.[1]

Although many misquote Montalbán as saying “rich Corinthian leather” or “fine Corinthian leather” in the commercial, he actually says that “soft Corinthian leather” is an available upholstery option for the car.[2]

Corinthian Leather is a marketing term that does not actually indicate any particular type of leather. Furthermore, Montalbán confirmed this during an interview with David Letterman, admitting that Corinthian leather means “nothing.”[3] According to one reference, Chrysler’s “Corinthian” leather was mass produced in a plant in Newark, New Jersey (not Corinth).

According to one source, the term was created by employees of the Young & Rubicam advertising agency.[4]

Morocco leather:

From Wikipedia, the free encyclopedia

• Interested in contributing to Wikipedia? •

Jump to: navigation, search

Made from sheepskin, morocco leather is dyed red on the grain side and then tanned by hand to bring up the grain in a bird’s-eye pattern.[1]

Alternate forms are also made of goatskin[2]

References:

Nappa leather:

From Wikipedia, the free encyclopedia

• Learn more about citing Wikipedia •

Jump to: navigation, search

Nappa leather or Napa leather is a full-grain leather, typically dyed, made from unsplit kid-, lamb– or sheep-skin by tanning with salts of chromium or aluminium sulfate, and noted for softness and durability. It is often used in high-quality leather products such as high-end furniture and accessories such as wallets and luggage. One example would be interiors of luxury vehicles.

Notes:

- B Ellis (1921), Gloves & Glove Trade, page 58,

- Nappa gloves are made from tawed leathers.

Ostrich leather:

From Wikipedia, the free encyclopedia:

• Learn more about citing Wikipedia •

Jump to: navigation, search

The purpose of this article is to illuminate the subject of ostrich leather further to give one a more thorough idea of the history, process, uses, and cataegorization of ostrich leather. Naturally, aspects and characteristics of ostrich skin will be revealed through this article, however, it will deal mostly with ostrich skin that has been tanned or otherwise cured.

A brief history:

The commercial farming of ostriches first began in the 1850s when pioneering farmers located in Oudtshoorn, South Africa, saw great economic potential in the harvesting of ostrich feathers[1]. Horse drawn carriages made large, dramatic hats fashionable. Ostrich feathers are some of the most intricate and grandiose in the world so it only made since to use them in this new rage. During this period of the late 19th and early 20th century, South African ostrich farmers made a fortune. However, the good times came to an end. Henry Ford began to mass-produce the automobile which made large stylish hats for women virtually obsolete. The onset of World War I put the final nail in the coffin of the ostrich feather industry. The same barons who were making a fortune soon found themselves on the verge of poverty. The future of the ostrich industry looked very grim indeed.

Over the next 50 years the entire industry bottomed out and maintained a minimal presence in the world. This status quo would not last, however. In 1945 the Klein Karoo region near Oudtshoorn set up a cooperative of farmers and speculators (“KKLK”) who would work together to build the ostrich industry. Eventually the demand for ostrich meat locally grew to a point where an abattoir was needed[2]. In 1963/64 the world’s first ostrich abattoir was erected in Klein Karoo by the KKLK to supply dried and fresh ostrich meat locally[3].The marketing of ostrich skin started in 1969/1970 when a leather tannery was built near the abattoir. Prior to this, there is very little known about the tanning process of ostrich skin. Most likely, ostrich skins were sent from the abattoir to tanneries in England and then sold to fashion houses. It appears that a group of South African entrepreneurs set out earlier in the 1960s in search of ways to tan ostrich skin. “I will give anything to see ostrich skins used,” said Gerhard Olivier. With Hannes Louw, Jurgens Schoeman and the tanner Johan Wilken, he traveled abroad for the first time in search of people who could tan ostrich leather[4]. They came across Arnold and Dianne de Jager, founders of a tannery in London, who offered to train a tanner for Klein Karoo. In 1970, the first ostrich skin tannery opened in Klein Karoo.

Ostrich leather was instantly popular in high fashion (haute couture) throughout Europe and the United States where it was used for cowboy boots. Notably, during the 1980s, demand was extremely high in the United States. During this period, apartheid and other political turmoil caused some countries, the United States included, to put pressure on South Africa in the form of trade sanctions. It was hard for ostrich leather to make it into the States, but it did. However, it came at a cost and the ostrich leather purveyors, brothers John G. Mahler and Wilfred Mahler of Dallas, TX, were the only importers of ostrich skin for many years. Just like the single channel KKLK, who had an iron grip on the exportation of the only viable ostrich skins, the Mahlers were able to control not only prices but also who got skins in the United States and how many they were allowed. Their control was so absolute that some bootmakers would be reprimanded by John if they sold his skins to other bootmakers[3]. The entire arrangement has been compared to the DeBeers diamond cartel.

In 1993 apartheid in South Africa ended. This event, combined with the fact that several droughts in Klein Karoo severely crippled the ostrich industry, forced the South African government to open up the exportation of ostrich stock. This allowed neighboring countries and even the U.S. to import and begin raising ostriches on their own. This effectively ended the strong monopoly enjoyed by South Africa and the for so long. It also ended the Mahler’s monopoly in the United States. More suppliers began to open up in the U.S. and, with less trade restrictions, were able to supply ostrich leather at lower prices. Now there are several ostrich ranches and tanneries in the U.S., but with a 150 year head start Klein Karoo is still considered the industry leader.

General description:

Tanned Ostrich Hide

Ostrich leather is unmistakable in its appearance; No other material looks similar to it. It is characterized by raised points that are localized to the center of the hide. The portion with these bumps is called the crown. It’s actually the back of the ostrich where the animal’s neck meets its body. The bumps are quill follicles where a feather used to reside. On the left and right side of the diamond shaped crown the skin is quite smooth. In fact, only about 1/3 of the whole skin has quill bumps. Since the crown is the most sought after portion and since it constitutes such a small area of the skin, “full quill” ostrich products are considerably expensive when compared to bovine leather. This, along with the fact that it is one of the strongest commercial leathers, leads ostrich leather to be seen as a luxury item.

The average size of a prepared ostrich skin which can be used with success in most applications is around 16 square feet. An 18 month old ostrich will typically yield a skin of this size. Of course, the older a bird is the larger its hide will be but quality suffers and the skin may be too thick for ideal use. A juvenile ostrich will yield smaller skins which are thinner but the quill pattern and size might be too small.

Ostrich leather is graded according to the number of defects in the crown area. A defect can be a hole, scratch, loose scab, a healed wound or bacterial damage but must be less than 40 mm x 40 mm in size.

Grade I – defects permitted in 1 quarter of the skin only

Grade II – defects in 2 quarters of the skin only

Grade II – defects in 3 quarters of the skin only

Grade IV – defects in 4 quarters of the skin

Ostrich leather is typically sold by the square foot and price is grade driven. For instance, a Grade I ostrich skin may cost $22/sq. ft. while a Grade III ostrich skin costs $19/sq. ft.

Uses of ostrich leather:

Traditionally, fashion has driven the demand for ostrich leather. Fashion houses successfully used ostrich leather in handbags for many years. Most designer brands have at least one purse made with ostrich leather. Footwear is another way in which designers showcase the material. But, by far the most widely used application is for ostrich leather boots. Just about every bootmaker uses ostrich and the demand for ostrich boots is higher than any other ostrich leather product[5]. Belts are another major accessory that utilize ostrich leather (most ostrich boots are purchased with a matching ostrich belt). Of course there are other uses for ostrich leather notably shoes, wallets and jackets. The cost for most items is usually between $500 to $5000; handbags and jackets are highest priced due to the shear amount of leather used.

Designer handbags in Ostrich leather are extremely popular as many luxury designers such as Prada, Marcela Calvet, Botega Venetta and Gucci, continue to make fashion statements with their wares made of exotic skins. Although such items are not inexpensive, women seek them out because they are simply beautiful and different. It is quite easy to recognize an ostrich handbag.

Different geographic regions have different demands for ostrich leather. For instance, Japan has an especially strong market for lady’s handbags while the southern United States has many consumers of ostrich boots.

Aside from fashion designers, the automotive industry is a heavy user of ostrich leather. Car seats, dashboards, motorcycle seats, and door panels can all be covered or accented with ostrich leather. Most after market car and motorcycle shops can alter seats by applying ostrich leather as seat inserts. Many luxury car manufacturers offer ostrich leather seats from the factory. This practice is especially popular in European countries.

Patent leather:

From Wikipedia, the free encyclopedia:

Patent leather is leather that has been given a high gloss, shiny finish. The original process was developed by Newark, New Jersey–based inventor Seth Boyden in 1818 with commercial manufacture beginning September 20, 1819. His process used a linseed oil–based lacquer coating. Modern patent leather usually has a plastic coating.

Patent leather is sometimes confused with poromeric imitation leathers such as DuPont’s Corfam and Kuraray Co.’s Clarino which are manmade materials with a similar glossy appearance.

Patent leather and poromerics are cleaned in a similar way. Dirt adhering to the coating can be removed with a damp cloth, using a mild soap if needed. Minor scratches and scuff marks in the coating itself can be removed using one of several special-purpose patent leather and poromeric cleaners on the market. With wear and tear, patent leather will eventually lose its glossy finish, but will still be smoother than most other types of leather, looking almost rubbery.

Patent leather and poromerics are used in applications where an eye-catching glossy appearance is the most important consideration. Examples include fashion items such as wallets and handbags, dance and uniform shoes, kinky boots and professional wrestling boots, and trench coats. In recent years patent leather has become a popular material for limited-edition sneakers made by companies such Nike, Bape, and Greedy Genius.

History:

Sporting a high gloss finish, patent leather has long been established as leather that is considered uptown and formal.[citation needed]

The history of patent leather begins in the early 19th century and owes its invention to Seth Boyden of Newark, New Jersey. During the year 1818, Boyden began to investigate the possibility of creating a version of leather that was treated in such a way that the material retained its desirable qualities of protection and durability. At the same time, this new type of leather would also have an appearance that would be decidedly more dressy than work boots and similar leather goods.

Using a formula that was based on a series of treatments using layers of linseed oil based coats, the new shiny leather began commercial production on 20 September 1819. Boyden’s efforts resulted in the production of glossy leather that quickly caught on as a complement for formal dress.

Patent leather begins as a superior grade of fine grain leather that undergoes a process to achieve the glossy look. Originally, this was accomplished by applying layers of a linseed oil finish to the leather, gradually creating the sleek appearance. As time went on, the invention of plastics impacted the methods for producing patent leather.

Plastic finishes were able to produce effects similar to the application of several treatments with linseed oil, with the advantage of considerably less monetary investment on the part of the producer. Over time, the development of synthetic resins further simplified the process and cut production costs even further, making the mass production of patent leather possible.

Characterized by a glass-like finish that catches the light, the typical patent leather accessory is a solid black. In addition to the mirror like finish, patent leather is also virtually waterproof, while still retaining a very flexible texture. The visual aspects of patent leather have made it a sought after material for formal accessories. Most men’s footwear produced to be worn with tuxedos are patent leather shoes. Many formal types of heels for women are also produced using patent leather. Clutches and small handbags for women are also made using patent leather, as well as some formal wallets and cigarette cases.

Poromeric imitation leather:

From Wikipedia, the free encyclopedia

• Ten things you may not know about Wikipedia •

Jump to: navigation, search

Sometimes referred to as poromerics, poromeric imitation leathers are a group of synthetic ‘breathable’ leather substitutes made from a plastic coating (usually a polyurethane) on a fibrous base layer (typically a polyester). The term poromeric was coined by DuPont as a derivative of the terms microporous and polymeric. The first poromeric material was DuPont’s ill-fated Corfam introduced in 1963 at the Chicago Shoe Show. Newer poromerics include Clarino made by Kuraray Co. of Japan

Poromeric imitation leather:

From Wikipedia, the free encyclopedia

• Ten things you may not know about Wikipedia •

Jump to: navigation, search

Sometimes referred to as poromerics, poromeric imitation leathers are a group of synthetic ‘breathable’ leather substitutes made from a plastic coating (usually a polyurethane) on a fibrous base layer (typically a polyester). The term poromeric was coined by DuPont as a derivative of the terms microporous and polymeric. The first poromeric material was DuPont’s ill-fated Corfam introduced in 1963 at the Chicago Shoe Show. Newer poromerics include Clarino made by Kuraray Co. of Japan.

|

|

Forms of leather:

There are a number of processes whereby the skin of an animal can be formed into a supple, strong material commonly called leather.

- Vegetable-tanned leather is tanned using tannin (hence the name “tanning”) and other ingredients found in vegetable matter, tree bark, and other such sources. It is supple and brown in color, with the exact shade depending on the mix of chemicals and the color of the skin. Vegetable-tanned leather is not stable in water; it tends to discolor, and if left to soak and then dry it will shrink and become less supple and harder. In hot water, it will shrink drastically and partly gelatinize, becoming rigid and eventually brittle. Boiled leather is an example of this where the leather has been hardened by being immersed in hot water, or in boiled wax or similar substances. Historically, it was occasionally used as armour after hardening, and it has also been used for book binding. This is the only form of leather suitable for use in leather carving or stamping.

- Chrome-tanned leather, invented in 1858, is tanned using chromium sulfate and other salts of chromium. It is more supple and pliable than vegetable-tanned leather, and does not discolor or lose shape as drastically in water as vegetable-tanned. It is also known as wet-blue for its color derived from the chromium. More esoteric colors are possible using chrome tanning.

- Aldehyde-tanned leather is tanned using glutaraldehyde or oxazolidine compounds. This is the leather that most tanners refer to as wet-white leather due to its pale cream or white color. It is the main type of leather used in chrome-free leather often seen in infant’s shoes and in automobiles made with chrome-free leather. Formaldehyde tanning (being phased out due to its danger to workers and the sensitivity of many people to formaldehyde) is another method of aldehyde tanning. Brain-tanned leathers fall into this category and are exceptionally water absorbent. Brain tanned leathers are made by a labor-intensive process which uses emulsified oils, often those of animal brains. They are known for their exceptional softness and their ability to be washed. Chamois leather also falls into the category of aldehyde tanning and like brain tanning produces a highly water absorbent leather. Chamois leather is made by using oils (traditionally cod oil) that oxidise easily to produce the aldehydes that tan the leather.

- Synthetic-tanned leather is tanned using aromatic polymers such as the Novolac or Neradol types. This leather is white in color and was invented when vegetable tannins were in short supply, i.e. during the Second World War. Melamine and other amino-functional resins fall into this category as well and they provide the filling that modern leathers often require. Urea-formaldehyde resins were also used in this tanning method until dissatisfaction about the formation of free formaldehyde was realised.

- Alum-tanned leather is tanned using aluminium salts mixed with a variety of binders and protein sources, such as flour, egg yolk, etc. Purists argue that alum-tanned leather is technically “tawed” and not tanned, as the resulting material will rot in water. Very light shades of leather are possible using this process, but the resulting material is not as supple as vegetable-tanned leather.

- Rawhide is made by scraping the skin thin, soaking it in lime, and then stretching it while it dries. Like alum-tanning, rawhide is not technically “leather”, but is usually lumped in with the other forms. Rawhide is stiffer and more brittle than other forms of leather, and is primarily found in uses such as drum heads where it does not need to flex significantly; it is also cut up into cords for use in lacing or stitching, or for making many varieties of dog chews.

Leather—usually vegetable-tanned leather—can be oiled to improve its water resistance. This supplements the natural oils remaining in the leather itself, which can be washed out through repeated exposure to water. Frequent oiling of leather, with mink oil, neatsfoot oil or a similar material, keeps it supple and improves its lifespan dramatically.

Leather with the hair still attached is called hair-on.

Leather types:

In general, leather is sold in three forms:

- Full-Grain leather or Top-Grain is referring to the upper section of a hide that contains the epidermis or skin layer. It refers to hides that have not been sanded, buffed or snuffed(otherwise known as Corrected) in order to remove imperfections on the surface of the hide. Only the hair has been removed from the epidermis. The grain remains in its natural state which will allow the best fiber strength, resulting in greater durability. The natural grain also has natural breathability, resulting in greater comfort for clothing. The natural Full-Grain surface will wear better than other leather. Rather than wearing out, it will develop a natural “Patina” and grow more beautiful over time. The finest leather furniture and footwear are made from Full-Grain leather. For these reasons only the best raw hide are used in order to create Full-Grain or Top-Grain leather. Full grain leathers can mainly be bought as two finish types: aniline and semi-aniline.

- Corrected-Grain leather is any Top-Grain leather that has had its surfaces sanded, buffed or snuffed in order to remove any imperfection on the surface due to insect bites, healed scars or brands. Top-Grain leather is often wrongly referred to as Corrected-Grain. Although Corrected-Grain leather is made from Top-Grain as soon as the surface is corrected in any way the leather is no longer referred to asTop-Grain leather. The hides used to create corrected leather are hides of inferior quality that do not meet the high standards for use in creating aniline or semi-aniline leather. The imperfections are corrected and an artificial grain applied. Most Correct leather is used to make Pigmented leather as the solid pigment helps hide the corrections or imperfections. Corrected grain leathers can mainly be bought as two finish types: semi-aniline and pigmented.

- Split leather is leather that is created from the fibrous part of the hide left once the Top-Grain of the raw hide has been separated from the hide. During the splitting operation the grain and drop split are separated. The drop split can be further split (thickness allowing) into a middle split and a flesh split. In very thick hides the middle split can be separated into multiple layers until the thickness prevents further splitting. Split leather then has an artificial layer applied to the surface of the split and is embossed with a leather grain. Splits can are also used to create Suede. The strongest suedes are usually made from grain splits (that have the grain completely removed) or from the flesh split that has been shaved to the correct thickness. Suede is “fuzzy” on both sides. Suede is less durable than top-grain. Suede is cheaper because many pieces of suede can be split from a single thickness of hide, whereas only one piece of top-grain can be made. However, manufacturers use a variety of techniques to make suede appear to be full-grain. For example, in one operation, glue is mixed with one side of the suede, which is then pressed through rollers; these flatten and even out one side of the material, giving it the smooth appearance of full-grain. Latigo is one of the trade names for this product. A reversed suede is a grained leather that has been designed into the leather article with the grain facing away from the visible surface. It is not a true form of suede.

The International Union of Leather Technologists and Chemist Societies has a full glossary of leather terms that can be found at IULTCS

Other less-common leathers include:

- Buckskin or brained leather is a tanning process that uses animal brains or other fatty materials to alter the leather. The resulting supple, suede-like hide is usually smoked heavily to prevent it from rotting.

- Patent leather is leather that has been given a high gloss finish. The original process was developed in Newark, New Jersey, by inventor Seth Boyden in 1818. Patent leather usually has a plastic coating.

- Shagreen is also known as Stingray skin/leather. Applications used in furniture production date as far back as the art deco period. The word “Shagreen” originates from France and is commonly confused with a shark skin and stingray skin combination.

- Vachetta leather is used in the trimmings of luggage and handbags, popularized by Louis Vuitton. The leather is left untreated and is therefore susceptible to water and stains. Sunlight will cause the natural leather to darken in shade, called a patina.

- Slink is leather made from the skin of unborn calves. It is particularly soft, and is valued for use in making gloves.

- Deer Skin is one of the toughest leathers, partially due to adaptations to their thorny and thicket filled habitats. Deerskin has been prized in many societies including indigenous Americans. Most modern deer skin is no longer procured from the wild, with “deer farms” breeding the animals specifically for the purpose of their skins. Large quantities are still tanned from wild deer hides in historic tanning towns such as Gloversville and Johnstown in upstate New York. Deer skin is used in jackets and overcoats, professional sporting equipment such as kendo bogu, as well as high quality personal accessories like handbags and wallets. It commands a high price due to its relative rarity and proven durability.

- Nubuck is top-grain cattle hide leather that has been sanded or buffed on the grain side, or outside, to give a slight nap of short protein fibers, producing a velvet-like surface.

There are two other descriptions of leather commonly used in specialty products, such as briefcases, wallets, and luggage.

- Belting leather is a full grain leather that was originally used in driving pulley belts and other machinery. It is often found on the surface of briefcases, portfolios, and wallets, and can be identified by its thick, firm feel and smooth finish. Belting leather is the only kind of leather used in luxury products that can retain its shape without the need for a separate frame; it is generally a heavy-weight of full-grain, vegetable-tanned leather.

- Nappa leather, or Napa leather, is chrome-tanned and is extremely soft and supple and is commonly found in higher quality wallets, toiletry kits, and other personal leather goods.

The following are not ‘true’ leathers, but contain leather material.

- Bonded Leather , or “Reconstituted Leather”, is not really a true leather but a man-made material composed of 90% to 100% leather fibers (often scrap from leather tanneries or leather workshops) bonded together with latex binders to create a look and feel similar to that of genuine leather at a fraction of the cost. Bonded leather is not as durable as other leathers, and is recommended for use only if the product will be used infrequently. One example of bonded leather use is in Bible covers.

- Bicast leather is a man-made product that consists of a thick layer of polyurethane applied to a substrate of low-grade or reconstituted leather. Most of the strength of bicast leather comes from the polyurethane coating. Bicast was originally made for the shoe industry and recently was adopted by the furniture industry. The original formula created by Bayer was fairly strong, but creating Bicast from the original recipe is expense. Most of the Bicast used today is created using inferior generic chemicals resulting in an inferior material. The result is a much stiffer product that tends to delaminate resulting in bubbles and cracking.

The vast majority of leather is sold according to its area. The leather is placed through pin-wheel or electronic measuring machines and its surface area is determined. The unit of measurement is square metre, square decimetre or square foot. The thickness is also important, and this is measured using a thickness gauge (the unit of measurement is millimetres, e.g., 1.8 mm is a standard thickness for a school shoe).

In some parts of the world top-grain thicknesses are described using weight units of ounces. Although the statement is in ounces only, it is an abbreviation of ounces per square foot. The thickness value can be obtained by the conversion:

- 1 oz/ft² = 1/64 inch (0.4 mm)

Hence, leather described as 7 to 8 oz is 7/64 to 8/64 inches (2.8 to 3.2 mm) thick. The weight is usually given as a range because the inherent variability of the material makes ensuring a precise thickness very difficult. Other leather manufacturers state the thickness directly in millimetres.

Leather from other animals:

Ostrich leather

Today, most leather is made of cattle skin, but many exceptions exist. Lamb and deer skin are used for soft leather in more expensive apparels. Deer and elk skin are widely used in work gloves and indoor shoes. Pigskin is used in apparel and on seats of saddles.

Kangaroo skin is used to make items which need to be strong but flexible, it is the material most commonly used in high quality bullwhips. Kangaroo leather is favored by some motorcyclists for use in Motorcycle Leathers specifically because of its lighter weight and higher abrasion resistance compared with cowhide, thus providing greater protecting in case of a fall on the roadway. Kangaroo leather is also used for high performance soccer footwear.

Leather made from more exotic skins has at different times in history been considered very beautiful. For this reason certain snakes and crocodiles have been hunted to near extinction.

In the 1970s, ostrich farming for their feathers became popular, and ostrich leather became available as a side product. There are different processes to produce different finishes for many applications, i.e., upholstery, footwear, automotive products, accessories and clothing. Ostrich leather is considered one of the finest and most durable in the world and is currently used by many major fashion houses such as Hermès, Prada, Gucci, and Louis Vuitton. Ostrich leather has a characteristic “goose bump” look because of the large follicles from which the feathers grew.

In Thailand, sting ray leather is used in wallets and belts in the same way as regular bovine leather. Sting ray leather is as tough and durable as hard plastic. The leather is often dyed black and covered with tiny round bumps in the natural pattern of the back ridge of an animal. These bumps are then usually dyed white to highlight the decoration. Leather clothing is also popular in Thailand.

In the United States, bison leather has become popular. It is used for gloves, jackets and some baseball gloves. It is rugged but supple and has a waxy feel.

Overall, leather comes from a variety of other sources, including the skins of cattle, hogs, goats, sheep, alligators, ostriches, kangaroos, & yaks.

There is quite a wide range of different animal leather used both for Leather garments as well as Leather Goods such as Ladies Handbags, Gents wallets, Ladies Purses, Leather Belts, File bags and other customized leather articles.

The most commonly used leather types are Cow leather, Sheep leather, Buffalo Leather and Ox leather. Of these, the most expensive is Cow leather and then Buffalo leather, Ox leather and Sheep leather respectively. The Sheep leather is quite famous for its softness and mostly used in leather garments; however due to certain restrictions of its overall size; it cannot be used for long coats and there Cow leather and Buffalo leather is widely used.

Leather production processes

Main article: Leather Production Processes

The leather manufacturing process is divided into 3 fundamental sub-processes: preparatory stages, tanning and crusting. All true leathers will undergo these sub-processes. A further sub-process, surface coating can be added into the leather process sequence but not all leathers receive surface treatment. It’s difficult to create a list of operations that all leathers must undergo, as there are so many types of leather.

The preparatory stages are when the hide/skin is prepared for tanning. Preparatory stages may include: preservation, soaking, liming, unhairing, fleshing, splitting, reliming, deliming, bating, degreasing, frizing, bleaching, pickling and depickling.

Tanning is the process converts the protein of the raw hide or skin into a stable material which will not putrefy and is suitable for a wide variety of end applications. The principal difference between raw hides and tanned hides is that raw hides dry out to form a hard inflexible material that when re-wetted (or wetted back) putrefy, whilst tanned material dries out to a flexible form that does not become putrid when wetted back. There is a large number of different tanning methods and materials that can be used, the choice is ultimately dependent on the end application of the leather. The most commonly used tanning material is chromium, which leaves the leather once tanned a pale blue colour (due to the chromium), this product is commonly called “wet blue”. The hides once they have finished pickling will typically be between pH of 2.8-3.2. At this point the hides would be loaded in a drum and immersed in a float containing the tanning liquor. The hides are allowed to soak (while the drum slowly rotates about its axle) and the tanning liquor slowly penetrates through the full substance of the hide. Regular checks will be made to see the penetration by cutting the cross section of a hide and observing the degree of penetration. Once a good even degree of penetration exists, the pH of the float is slowly raised in a process called basification. This basification process fixes the tanning material to the leather and the more tanning material fixed the higher the hydrothermal stability and increased shrinkage temperature resistance of the leather. The pH of the leather when chrome tanned would typically finish somewhere between 3.8-4.2.

Crusting is when the hide/skin is thinned, retanned and lubricated. Often a coloring operation is included in the crusting sub-process. The chemicals added during crusting have to be fixed in place. The culmination of the crusting sub-process is the drying and softening operations. Crusting may include the following operations: wetting back, sammying, splitting, shaving, rechroming neutralisation, retanning, dyeing, fatliquoring, filling, stuffing, stripping, whitening, fixation, setting, drying, conditioning, milling, staking and buffing.

For some leathers a surface coating is applied. Tanners refer to this as finishing. Finishing operations may include: oiling, brushing, padding, impregnation, buffing, spraying, roller coating, curtain coating, polishing, plating, embossing, ironing, ironing/combing(for hair-on)and glazing.

Role of enzymes in leather production:

Enzymes like proteases, lipases and amylases have an important role in the soaking, dehairing, degreasing, and bating operations of leather manufacturing.

Proteases are the most commonly used enzymes in leather production. The enzyme used should not damage or dissolve collagen or keratin, but should be able to hydrolyse casein, elastin, albumin and globulin-like proteins, as well as non-structured proteins which are not essential for leather making. It is especially important to hydrolyse the elastin if the leather is to be limed, or treated with calcium hydroxide; if not treated properly before liming, the elastin will harden and the grain will be loose. This process is called bating[1].

Lipases are used in the degreasing operation to hydrolyse fat particles embedded in the skin[2]..

Amylases are used to soften skin, to bring out the grain, and to impart strength and flexibility to the skin. These enzymes are rarely (if ever) used.

Preservation and conditioning of leather:

The natural fibers of leather will break down with the passage of time. Acidic leathers are particularly vulnerable to red rot, which causes powdering of the surface and a change in consistency. Damage from red rot is aggravated by high temperatures and relative humidities, and is irreversible.

Exposure to long periods of low relative humidities (below 40%) can cause leather to become desiccated, irreversibly changing the fibrous structure of the leather.

Various treatments are available such as conditioners, but these are not recommended by conservators since they impregnate the structure of the leather artifact with active chemicals, are sticky, and attract stains.

Leather in book binding:

Leather used in book binding has many of the same preservation needs: protection from high temperatures, high relative humidity, low relative humidity, fluctuations in relative humidity, light exposure, dust buildup, pollution, mold, and bug infestation.[3][4]

For books with red rot, acid-free phase boxes and/or polyester dust jackets (Dupont Mylar Type D® or ICI Mellinex 516®) are recommended to protect the leather from further handling damage and as well as to prevent the residues from getting on hands, clothes, the text block, and nearby books.[5]

The debate on the use of dressings for preservation of book bindings has spanned several decades as research and experimental evidence slowly accumulated. The main argument is that, done incorrectly, there are multiple disadvantages and that, done correctly, there is little to no preservation advantage. Pamphlets and guidelines give numerous downsides to dressings use, including: the dressing becoming increasingly acidic, discolor and stain the leather, oxidize (penetration and expansion of oils including displacement and weakening of fibers) and stiffen, leave a sticky surface, collect dust, wick into adjacent materials, form unstable surface spews, encourage biological deterioration and mold growth, block surface porosity, impede further treatment, wet and swell the leather, affect surface finishes, and desiccate or dry out the leather.[6]Meanwhile, scientific experiments have shown no great benefits.[7]The main authorities on the subject therefore discourage it, with a caveat for special cases done under the direction of a conservator.[5][6][3]

Working with leather:

Main article: Leather crafting

Leather can be decorated by a variety of methods, including pyrography and beading.

Cordwain:

Cordwain, once a synonym to Cordovan (through Old French cordewan) meaning “from Córdoba”. Painted or gilded embossed leather decoration for walls, a 12th century north African style, was introduced to Spain (hence it is sometimes referred to as ‘Spanish leather’). Around the turn of the 15th-16th century the technique reached Flanders and Brabant in the Low Countries. Though there were craftsmen in several cities (such as Antwerp, Brussels, Ghent), the major handicraft center for this cordwain was Mechelen, where it was mentioned as early as 1504. Since the second half of the 18th century, this luxurious artisan product is no longer made.[8] Cordwainer is still used to describe someone in the profession of shoemaking.

Leather in modern culture:

Leather, due to its excellent abrasion and wind resistance, found a use in rugged occupations. The enduring image of a cowboy in leather chaps gave way to the leather-jacketed and leather-helmeted aviator. When motorcycles were invented, some riders took to wearing heavy leather jackets to protect from road rash and wind blast; some also wear chaps or full leather pants to protect the lower body. Many sports still use leather to help in playing the game or protecting players: due to its flexible nature it can be formed and flexed for the occasion.

As leather can also be a metonymical term for objects made from it, the term leathering is as logical as tanning in the sense of a physical punishment (such as a severe spanking) applied with a leather whip, martinet etcetera.

Leather fetishism is the name popularly used to describe a fetishistic attraction to people wearing leather, or in certain cases, to the garments themselves. The word leather itself became synonymous with sado-masochism in the 1980s after achieving that status in homosexual jargon in the 1970s.

A number of rock groups, particularly heavy metal groups such as Judas Priest and Scorpions, are well-known for wearing leather clothing. Leather clothing, particularly jackets, almost come as standard in the heavy metal subculture. Extreme metal bands, especially black metal bands, have extensive leather clothing, i.e. leather trousers, accessories etc.

In today’s times, many cars and trucks come optional or standard with ‘leather’ seating. This can range from cheap vinyl material, found on some low cost vehicles, to Nappa leather, found on luxury car brands like Mercedes-Benz and Audi.

Religious sensitivities to leather:

In countries with harmonious multi-religious environments, leather vendors are typically careful to clarify the kinds of leather used in their products. For example, leather shoes will bear a label identifying the animal from which the leather was taken. In this way, a follower of Islam would not accidentally purchase pigskin leather, and a Hindu would avoid cow leather.

Such taboos increase the demand for religiously neutral leathers like ostrich and deer.

Judaism forbids wearing leather-soled shoes during Yom Kippur and during mourning.

In muslim countries the products made in Leather were normally banned as due to the religious concerns imposed by some islamic scholars but in the mid of 20th century some eminent scholars from Muslim world have made significant efforts to bring awareness about this issue amongst the people which ultimately starts the trend of using leather products especially leather jackets, wallets, handbags and lot of other customized leather articles.

Concern for animals and alternatives:

Some vegan and animal rights activists have boycotted use of all leather items, believing the practice of wearing animal hides is unnecessary and vulgar in today’s society. Animal rights groups such as PETA have issued fact sheets calling for boycotts and encouraging use of alternative materials such as synthetic leathers produced from petro-chemicals.

Many pseudo-leather materials have been developed, allowing those who wish to wear leather-like garments to do so without actually wearing leather. One example of this is vegan microfiber, which claims to be stronger than leather when manufactured with strength in mind. Vinyl materials, Pleather, Durabuck, NuSuede, Hydrolite, and other alternatives exist, providing some features similar to leather. Drawbacks include the fact that the product is inorganic and not biodegradable along with concerns related to pollution in the production process.

See also:

Types of leather:

- Aniline leather,a leather treated with aniline as a dye

- Artificial leather, a fabric of finish intended to substitute for leather

- Bicast leather, a synthetic upholstery product

- Boiled leather, a historical construction material

- Bonded Leather, man-made material composed of leather fibers

- Chamois leather, leather made from the skin of the mountain antelope or Chamois

- Corinthian leather, a marketing term used by Chrysler in the 1970s

- Morocco leather, a type of sheepskin dyed red

- Nappa leather, a full-grain leather

- Ostrich leather, leather from an ostrich

- Patent leather, leather with a high gloss and shiny finish

- Pleather, a term for artificial leather

- Poromeric imitation leather, a group of synthetic leather substitutes

- Vegan leather, an artificial alternative to traditional leather

Leather fabrication:

- Leather carving, a process of cutting and stamping to give a three-dimensional appearance

- Leather crafting, the practice of making leather into crafts or pieces of art

- Liming (leather processing), a process of treating leather

- British Museum leather dressing, a conservator’s treatment for display items

- Tanning

|

|

Tanning

From Wikipedia, the free encyclopedia

• Learn more about using Wikipedia for research •

Jump to: navigation, search

This article is about making hides into leather. For the natural darkening of living human skin, see sun tanning.

Tanned leather in Marrakech

| This article does not cite any references or sources. (April 2007) Please help improve this article by adding citations to reliable sources. Unverifiable material may be challenged and removed. |

Tanning is the process of converting putrescible skin into non-putrescible leather, usually with tannin, an acidic chemical compound that prevents decomposition and often imparts color. Tanning leather involves a process which permanently alters the protein structure of skin so that it can not ever return to rawhide. Making rawhide does not require the use of tannin and is made simply by removing the flesh and then the hair by way of soaking in an aqueous solution (often called liming when using lime and water or bucking when using wood ash (lye) and water), then scraping over a beam with a somewhat dull knife, and then leaving to dry, usually stretched on a frame so that it dries flat. The two aforementioned solutions for removing the hair also act to clean the fiber network of the skin and therefore allow penetration and action of the tanning agent.

Ancient methods of tanning:

Tanneries at Fez

In ancient history, tanning was considered a noxious or “odiferous trade” and relegated to the outskirts of town, amongst the poor. Indeed, tanning by ancient methods is so foul smelling that tanneries are still isolated from those towns today where the old methods are used. The ancients used leather for waterskins, bags, harnesses, boats, armor, quivers, scabbards, boots and sandals. Around 2500 BC, the Sumerians began using leather, affixed by copper studs, on chariot wheels.

Skins typically arrived at the tannery dried stiff and dirty with soil and gore. First, the ancient tanners would soak the skins in water to clean and soften them. Then they would pound and scour the skin to remove any remaining flesh and fat. Next, the tanner needed to remove the hair fibers from the skin. This was done by either soaking the skin in urine, painting it with an alkaline lime mixture, or simply letting the skin putrefy for several months then dipping it in a salt solution. After the hair fibers were loosened, the tanners scraped them off with a knife.

Once the hair was removed, the tanners would bate the material (see below) by pounding dung into the skin or soaking the skin in a solution of animal brains. Among the kinds of dung commonly used were that of dogs or pigeons. Sometimes the dung was mixed with water in a large vat, and the prepared skins were kneaded in the dung water until they became supple, but not too soft. The ancient tanner might use his bare feet to knead the skins in the dung water, and the kneading could last two or three hours.

It was this combination of urine, animal feces and decaying flesh that made ancient tanneries so odiferous.

Children employed as dung gatherers were a common sight in ancient cities. Also common were “piss-pots” located on street corners, where human urine could be collected for use in tanneries or by washerwomen. In some variations of the process, cedar oil, alum or tannin were applied to the skin as a tanning agent. As the skin was stretched, it would lose moisture and absorb the agent.

Leftover leather would be turned into glue. Tanners would place scraps of hides in a vat of water and let them deteriorate for months. The mixture would then be placed over a fire to boil off the water to produce hide glue.

Variations of these methods are still used by do-it-yourself outdoorsmen to tan hides. The use of brains and the idea that each animal (except buffalo) has just enough brains for the tanning process have led to the saying “Every animal has just enough brains to preserve its own hide, dead or alive.”

Modern methods of tanning:

Tanneries of Marrakech

Two men pressing the leather near the end of the tanning process in an American tannery. circa: 1976

The first stage is the preparation for tanning. The second stage is the actual tanning and other chemical treatment. The third stage, known as retanning, applies retanning agents and dyes to the material to provide the physical strength and properties desired depending on the end product. The fourth stage is used to apply finishing material to the surface or finish the surface without the application of any chemicals if so desired. This final stage is known as finishing.

Preparing hides begins by curing them with salt. Curing is employed to check putrifaction of the protein substance (Collagen) because of the chance of bacterial infection due to the time lag that might occur from procuring it to processing it. It removes the excess water from the hides and skins where water flows from inside because of difference in osmotic pressure. Thus the moisture content of hides and skins get greatly reduced.In wet-salting, the hides are heavily salted, then pressed into packs for about 30 days. In brine-curing the hides are agitated in a salt water bath for about 16 hours. Generally speaking, methods employed for curing greatly make the chance of bacterial growth unfavorable. Thus curing is also done by preserving the hides and skins at a very low temperature

The hides are then soaked in clean water to remove the salt and mainly to bring back the moisture content to a desirable level so that the hide or skin can be treated with chemicals in an aqueous medium. This process is known as “Soaking” and sometimes a hydrating agent is also employed along with water in a very low percentage for hides and skins which have become very dry.

Liming Process of Hides & Skins:

After soaking, the soaked hides and skins are taken for the next operation where these are treated with milk of lime with or without the addition of sharpening agents like sulfide, cyanides, amines, etc. The objective of this operation are mainly to:

(1) Remove the hairs, nails and other keratinous matters (2) Remove some of the interfibrillary soluble proteins like mucins (3) Swell up and split up the fibers to the desired extent (4) Remove the natural grease and fats to some extent (5) Bring the collagen to a proper condition for satisfactory tannage

The weakening of hair is dependent on the break down of the disulfide link of the amino acid called cystine, which is the characteristic of the keratin class of protein like hair and wools. The hydrogen atoms supplied by the sharpening agent reduce the cystine molecule to cystine and the covalent links are ruptured.

The iso electric point of the collagen is also shifted to around 4.7, due to liming which is more towards an acidic tannage.

Unhairing Agents used during liming are:

(1) Sodium Sulphide (2) Sodium Hydroxide (3) Sodium Hydrosulfite (4) Arsenic Sulphide (5) Calcium Hydrosulfide (6) Dimethyl Amine (7) Sodium Sulphydrate

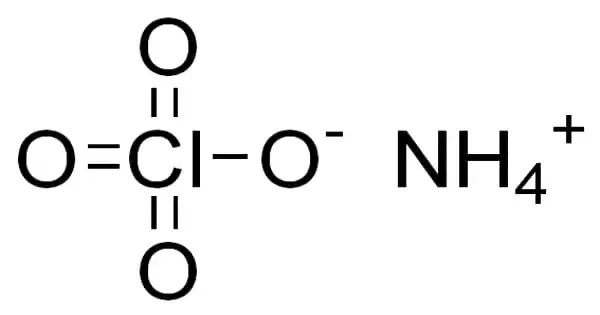

The majority of hair is then removed using a machine, with remaining hair being removed by hand using a dull knife, a process known as scudding. Depending on the end use of the leather, hides may be treated with enzymes to soften them in a process called “bating”. But before bating,the pH of the collagen is brought down to a lower level so that enzymes might act on it. This process is known as “Deliming”. Once bating is complete, the hides and skins are treated with a mixture of common salt and Sulphuric acid in case a mineral tanning to be done.This is done to bring down the pH of collagen to a very low level so as to facilitate the penetration of mineral tanning agent into the substance. This process is known as “Pickling”. The common salt penetrates the substance twice as fast as the acid and checks the ill effect of sudden drop of pH.

Tanning can be performed with either vegetable or mineral methods. Before tanning, the skins are unhaired, degreased, desalted and soaked in water over a period of 6 hours to 2 days. To prevent damage of the skin by bacterial growth during the soaking period, biocides, such as pentachlorophenol, are used.

Vegetable tanning uses tannin (this is where the name tanning comes from). Tannin occurs naturally in bark. The primary barks used in modern times are chestnut, oak, tanoak, hemlock, quebracho, mangrove, wattle and myrobalan. Hides are stretched on frames and immersed for several weeks in vats of increasing concentrations of tannin. Vegetable tanned hide is flexible and is used for luggage and furniture.

Mineral tanning usually uses chromium in the form of basic chromium sulfate. It is employed after picking. Once the desired level of penetration of chrome into the substance is achieved,the pH of the material is raised again to facilitate the process. This is known as Basification. In the raw state chrome tanned skins are blue and therefore referred to as “wet blue”. Chrome tanning is faster than vegetable tanning (less than a day for this part of the process) and produces a stretchable leather which is excellent for use in handbags and garments. (Encarta, 2003)

Depending on the finish desired, the hide may be waxed, rolled, lubricated, injected with oil, split, shaved and, of course, dyed. Suedes, nubucks, etc. are finished by raising the nap of the leather by rolling with a rough surface.

Another use:

The term tanning is also used metaphorically for a hiding in the sense of physical punishment (such as a severe spanking) which leaves clear marks (reddening, stripes or even scars) on the beaten skin.

References:

- Microsoft Encarta, 2003

|

|

Terms | Services | Favourite Links | Site Map

|

|

Terms | Services | Favourite Links | Site Map

Leather crafting:

From Wikipedia, the free encyclopedia

• Learn more about citing Wikipedia •

Jump to: navigation, search

Modern leather-working tools

Leather crafting is the practice of making leather into craft objects or works of art, using shaping techniques, coloring techniques or both.

Leather coloring:

A dyed leather carving

Leather dyeing usually involves the use of spirit or alcohol based dyes where alcohol quickly gets absorbed into moistened leather, carrying the pigment deep into the surface. “Hi-liters” and “Antiquing” stains can be used to add more definition to patterns. These have pigments that will break away from the higher points of a tooled piece and so pooling in the background areas give nice contrasts. Leaving parts unstained also provides a type of contrast. The predominant brand of leather dye is Fiebing’s Leather Dye.

Alternatives to spirit stains might include a number of options. Shoe polish can be used to dye and preserve leather. Oils such as neatsfoot or linseed can be applied to preserve leather but darkens them. A wax paste more often than not serves as the final coat.

Sweat and grime will also stain and ‘antique’ leather over time. Gun holsters, saddlebags, wallets and cantanas used by cowboys and buccaroos were rarely colored in the Old West. The red, brown, and black tones develop naturally through handling and as the oiled leathers absorb the rays of the desert sun.

Due to changing environmental laws, alcohol-based dyes are soon to be unavailable. There are currently water-based alternatives available, although they tend not to work as well.

Leather painting:

Leather painting differs from leather dyeing in that paint remains only on the surface while dyes are absorbed into the leather. Due to this difference, leather painting techniques can not be used on items that can or must bend nor on items that receive friction, such as belts and wallets. Under these conditions, the paint will crack and flake off. A flat piece of leather, backed with a stiff board is ideal and common, though three-dimensional forms are possible so long as the painted surface remains secured.

Acrylic paint is a common medium, often painted on tooled leather pictures, backed with wood or cardboard, and then framed. Unlike photographs, leather paintings are displayed without a glass cover, to prevent mold.

Leather carving:

Main article: Leather carving

Leather carving entails using metal implements to compress moistened leather in such a way as to give a three dimensional appearance to a two dimensional surface. The surface of the leather is not intended to be cut through, as would be done in filigree.

The main tools used to “carve” leather include: swivel knife, veiner, beveler, pear shader, seeder, cam, and background tool. The swivel knife is held similar to pencil and drawn along the leather to outline patterns. The other tools are punch-type implements struck with a wooden, nylon or rawhide mallet. The object is to add further definition with them to the cut lines made by the swivel knife.

In the United States and Mexico, the western floral style, known as “Sheridan Style”, of carving leather predominates. Usually, these are stylized pictures of acanthis or roses. California, Texas, and a few other styles are common. By far the most preeminent carver in the United States was Al Stohlman. His patterns and methods have been embraced by many hobbyists, scout troops, reenacters, and craftsmen.

Leather stamping:

Examples of geometric stamping on leather.

Leather stamping involves the use of shaped implements (stamps) to create an imprint onto a leather surface, often by striking the stamps with a mallet.

Commercial stamps are available in various designs, typically geometric or representative of animals. Most stamping is performed on vegetable tanned leather that has been dampened with water, as the water makes the leather softer and able to be compressed by the design being pressed or stamped into it. After the leather has been stamped, the design stays on the leather as it dries out, but it can fade if the leather becomes wet and is flexed. To make the impressions last longer, the leather is conditioned with oils and fats to make it water-proof and prevent the fibe