Introduction:

Beximco Textiles Ltd. (the “Company”) was incorporated in Bangladesh as a Public Limited Company with limited liability on 8 March 1994 and commenced commercial operation in 1995 and also went into the public issue of shares and debentures in the same year. The shares of the Company are listed in the Dhaka and Chittagong Stock Exchanges of Bangladesh.

Bextex Ltd. is the most modern composite mill in the region. Bextex Ltd. has an installed capacity of 299 high-speed air-jet looms in its weaving section and a high-tech dyeing and finishing section with a capacity of 100,000 yards of finished fabric per day. This company is located at the BeximcoIndustrial Park.

Strong business ethics, excellences in business, creating a productive work environment, continuous improvement through sound corporate governance and dynamic employee Engagement have been at the function of the organization to become the leading composite factory in Bangladesh.

General Information about the factory:

FACTORY NAME: BEXIMCO TEXTILES LIMITED

LOCATION: Beximco Industrial Park,

Chokroborty,

(5 km north from DEPZ )

Address :

Operational HQ

Beximco Textiles Limited,

BeximcoIndustrial Park,

Sarabo, Kashimpur, Gazipur.

Corporate HQ

17 Dhanmondi R/A, Road No. 2

Dhaka -1205, Bangladesh

Phone: 880-2-8611891-5, 8618220-7

9677701-5, 7701165

E-mail: beximchq@bextex.net

Web Site: www.bextex.net

Sponsors :

World Bank, M Arubeni

CDC, DEG.

Sonali Bank

Local office- Motejheel C/A, Dhaka-1000.

City Bank N.A.

ChamberBuilding,

122-124, Motijheel C/A, Dhaka-1000.

State Bank of India,

24-25, Dilkusha C/A, Dhaka.

Standard Chatard Bank ,

18-20, Motijheel C/A, Dhaka-1000.

BEX TEX PROFILE

Factory : Sarabo, Kashimpur, Gazipur.

Date of incorporation : 30 May, 1984

Commercial production : 1990

Business line : Manufacturing & Marketing of high

Quality fabric.

Listing status : Public listed company

Stock Exchange listing : Dhaka & Chittagong

Authorized capital in Taka : 3000 million Taka

Paid up capital : 1,882.50 Million Taka

Factory Equipment : Different types of weaving,

Knitting, Dyeing, Cutting,

Sewing, Finishing and

Generator machines

Supplied by mostly

Germany, Italy, U.K,

U.S.A., Japan, Taiwan etc.

Number of Shareholders : 37,929

Number of Woven loom installed : 293

Number of spindled installed : 119,520

Number of Denim loom installed : 56

Number of circular knit machine installed: 30

Production Capacity : 28 Million LM

Number of employees : 5181

Web site : www.beximco.org

Owners of the mill:

- Ø A S F Rahman

Chairman.

- Ø Salman F Rahman

Vice Chairman.

- Ø M A Qasem

Director.

- Ø A B Siddiqur Rahman

Director.

MANAGEMENT TEAM:

- Ø Syed Naved Husain, Chief Executive Officer.

- Ø Sardar Ahmed Khan, Chief Operating Officer.

- Ø Ajay Pratap Singh, Chief Financial Officer.

COMPANY SECRETARY:

- Ø Md. Asad Ullah, FCS

Mission:

BEX TEX Ltd. is a full service vendor with strong vertically integrated production facilities as well as creative & analytical capabilities which clearly set us apart from most other South Asian vendors. Each of their activities must benefit and add value to the Common wealth of our Society. We firmly believe that, in the final analysis we are Accountable to each of the Constituents with whom we interact; namely: our Employees, our valued Customers, our suppliers, our business associates, our Shareholders and our fellow Citizens.

Vision:

• Gain market leadership in high value added apparel in USA & Europe.

• Use “Innovation” & “Speed” as prime drivers, rather than cotton & cheap labor.

• Dominate these markets in high quality:

- Men’s, Women’s, Children dresses.

- Shirts ( formal & Casual )

- Blouses (formal & casual), Skirts, Jackets.

- Jeans & Casual non – denim bottoms.

- Knitted tops & bottoms.

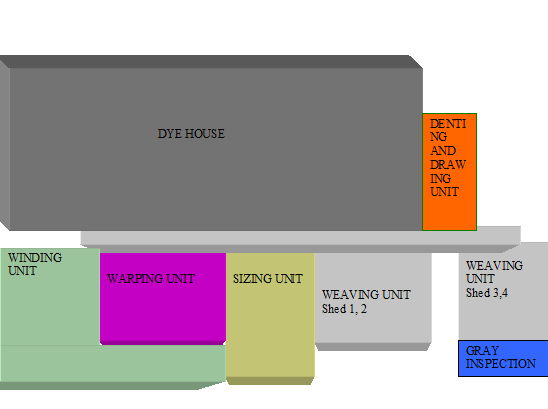

LAY OUT OF BTL:

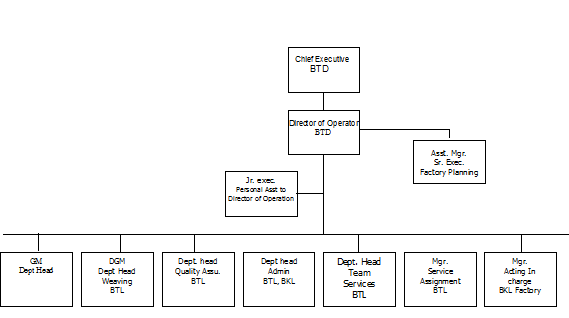

ORGANIZATIONAL CHARTS:

1. Organization chart – Overall

|

|

Org. chart for Bextex Ltd.:

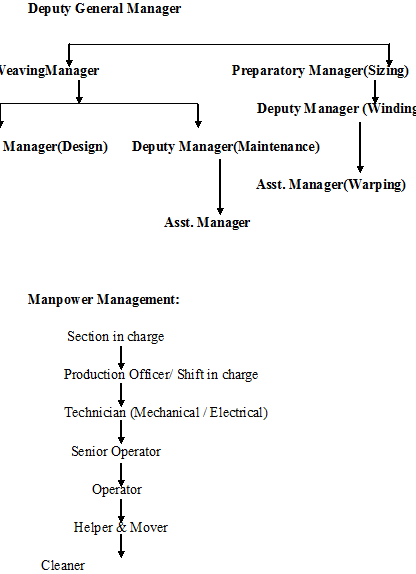

2. Org. chart of Beximco Textile Ltd. (Fabric Preparation):

Products:

Yarn Products:

| ||||||||||||||||||||||||||||||||||||||||||||||||

| Honorable Buyers:

Calvin Klein J.C Penny Long Street Rocha Wear VAN Heusen Zara Arizona H & M Levis Tom Tailor Next Antigua

| ||||||||||||||||||||||||||||||||||||||||||||||||

WOVEN FABRIC LOOMS:

No. of looms installed: 299

No. of looms actually operated: 299

Output capacity (Lm.):

Installed capacity: 40,800,000 Lm

Actual production: 34,966,037 Lm

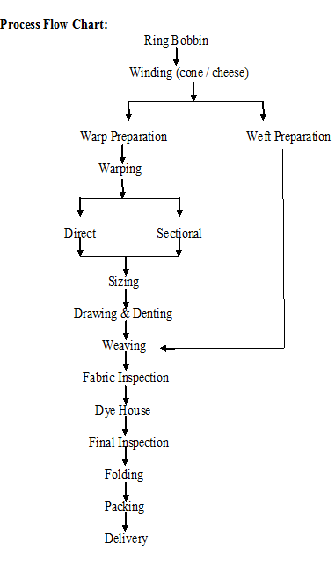

WINDING:

Definition: winding is a process of wounding of yarn to form yarn packages.

Types of winding: there are two types of winding-

- Soft Winding

- Hard Winding.

Machine Specification:

| Types of Winding | Brand Name | Country of origin | No of M/C | Speed |

| Soft Winding | FADIS Winder | Switzerland | 2 | 650m/min |

| HARISH Winder | Switzerland | 1 | 650m/min | |

| RJK Winder | India | 2 | 650m/min | |

| Hard Winding | Textool Winder | Switzerland | 10 | 650m/min |

| RJK Winder | India | 2 | 650m/min | |

| HARISH Winder | Switzerland | 3 | 650m/min | |

| KAMITSU Winder | Japan | 4 | 650m/min | |

| 24 | ||||

Key Accessories: Cone diameter gauge.

Chemical Used: Paraffin wax (rarely used).

WARPING:

Definition: To convert supply yarn package or reprocessed cone into a sheet of yarn comprising of predetermined number, length and tension.

Types of Warping:

- Direct Warping: for solid dyed grey production.

- Sectional Warping: for yarn dyed grey production.

| Types of Warping | Brand Name | Country of Origin | No of M/C | Creel Capacity | Speed |

| Direct Warping | KAWAMOTO | Japan | 2 | 550 | 550m/min |

| BENINGER (ZC-R-1800) | Switzerland | 2 | 640 | 600m/min | |

| Sectional Warping | BENINGER Supertronic-2200 | Switzerland | 3 | 720 | 600m/min |

Machine Specification:

Count wise Creel Tension in BENINGER:

| COUNT(Ne) | TENSION(CN) |

| 16 | 27 |

| 20 | 22 |

| 30 | 15 |

| 40 | 11 |

| 45 | 10 |

| 50 | 09 |

| 60 | 07 |

Sectional Warping Calculation:

Warp Width × Ends/Section

Width (mm) =

Total no of ends

Total no of ends

Ends/cm =

Warp Width (cm)

dtex× Total no of ends × Cone figure

Feed 1 =

10 × Warp Width (mm) × Density

Dtex = Grams/10000 m Yarn

Density = Grams/dm3

Cone Figure = 5

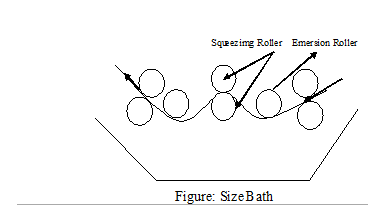

SIZING:

Definition: the process by which warp yarn is chemically treated for strengthening, reducing hairiness and to make more flexible.

Machine Specification:

| Brand Name | Country of origin | No of Size Bath | Beam Creel Capacity |

| BENINGER Zell | Switzerland | 1 | 20 |

| BENINGER Zell | Switzerland | 2 | 20 |

| KAWAMOTO | Japan | 1 | 16 |

Chemical Used for Sizing:

- Adhesive Material: modified starch, synthetic chemicals e.g. Kollotex 5, Avetex K.

- Chemicals: Quicksolon SPR.

- Acrylic Sizing Agent: e.g. size CA20.

- Lubricants Softener: Solwax -50, Mutton Tallow.

Size Recipe for Grey Yarn:

H2O = 400L

Starch = 50 kg

PVA (SPR) = 32 kg

Acrylic (Trisize) = 15 kg

Soul Wax = 5 kg

Size Recipe for Dyed Yarn:

H2O = 490L

Starch = 50 kg

PVA (SPR) = 25 kg

Acrylic (Trisize) = 12 kg

Soul Wax = 5 kg

- Ø Size Box Temperature = 85°c

- Ø Cylinder Dryer Temperature = 125°c

- Ø Refractrometer is used to check the dispersion of size materials.

| M/C no | Total Ends | Construction | Refrectrometer % | Pick Up % | Moisture % | Speed | Warp Tension N | Size Tension N | Strech % |

| 2 | 8450 | 40×40/133×100 | 12 | 17.5 | 6.0 | 40 | 4200 | 4190 | 0.98 |

| 1 | 7080 | 40×40/20×70 | 12 | 16.8 | 6.0 | 38 | 2658 | 2630 | 1.0 |

| 2 | 8450 | 40×40/130×90 | 12 | 16.2 | 6.0 | 40 | 4200 | 4192 | 0.98 |

| 1 | 7080 | 40×40/130×90 | 12 | 16.2 | 6.0 | 38 | 1961 | 1940 | 0.98 |

| 1 | 7080 | 40×40/130×90 | 12 | 16.2 | 6.0 | 38 | 1961 | 1936 | 0.98 |

| 2 | 8450 | 40×40/130×90 | 12 | 15.8 | 6.0 | 38 | 4114 | 4108 | 0.98 |

| 2 | 5900 | 20×16/100×80 | 10 | 14.1 | 6.5 | 30 | 3923 | 3906 | 1.0 |

Chart for different parameters used in sizing for different construction:

Weaving:

Definition: The process of interlacement of two sets of yarn named warp & weft by the means of weaving machine or loom to produce woven fabric is called weaving.

Machine Specification:

| Model | Shedding Device | Weft insertion capacity | No of loom | Maximum RPM | Country of origin |

| Toyoda, JAT 600RS190 | Negative cam shedding | 2 | 82 | 720 | Japan |

| Toyoda, JAT 600RS190 | Negative cam shedding | 4 | 30 | 720 | Japan |

| Toyoda, JAT 600RS190 | Electronic Dobby | 2 | 16 | 620 | Japan |

| Toyoda, JAT 600RS190 | Electronic Dobby | 6 | 16 | 620 | Japan |

| Toyoda, JAT 610RS190 | Electronic Dobby | 4 | 4 | 620 | Japan |

| Toyoda, JAT 610RS190 | Negative cam shedding | 4 | 98 | 720 | Japan |

| Toyoda, JAT 610RS190 | Negative cam shedding | 6 | 36 | 720 | Japan |

| Toyoda, JAT 610RS190 | Twin Beam | 4 | 10 | 720 | Japan |

| Toyoda, JAT 710 Eurotech | Positive cam shedding | 4 | 7 | 1200 | Japan |

| 299 | |||||

Lay out plan of Weaving Section:

Chart for loom stops, production, RPM and efficiency in A shift for different looms (5) which are run by a operator:

Loom No 230:

| Construction | Causes of stoppages | Times | min | Production | Efficiency % | RPM |

| 40×322 / 120×70 | Warp Miss | 12 | 52 | 25.5 m | 29.3 | 496 |

| WF1 Miss (1) | 4 | 6 | ||||

| WF1 Miss (2) | 12 | 19 | ||||

| WF2 Miss (1) | 0 | 0 | ||||

| WF2 Miss (2) | 6 | 89 | ||||

| Manual Stops | 4 | 54 | ||||

| Others | 1 | 0 |

Loom No 231:

| Construction | Causes of stoppages | Times | min | Production | Efficiency % | RPM |

| 40×(40+40)/120×70 | Warp Miss | 13 | 132 | 26 m | 39.4 | 394 |

| WF1 Miss (1) | 0 | 0 | ||||

| WF1 Miss (2) | 2 | 16 | ||||

| WF2 Miss (1) | 1 | 9 | ||||

| WF2 Miss (2) | 0 | 0 | ||||

| Manual Stops | 0 | 0 | ||||

| Others | 1 | 5 |

Loom No 232:

| Construction | Causes of stoppages | Times | min | Production m | Efficiency % | RPM |

| 40×40 / 120×70 | Warp Miss | 15 | 98 | 20.2 m | 29.2 | 495 |

| WF1 Miss (1) | 9 | 16 | ||||

| WF1 Miss (2) | 2 | 5 | ||||

| WF2 Miss (1) | 22 | 47 | ||||

| WF2 Miss (2) | 1 | 1 | ||||

| Manual Stops | 4 | 51 | ||||

| Others | 0 | 0 |

Loom No 233:

| Construction | Causes of stoppages | Times | min | Production | Efficiency % | RPM |

| 40×40 / 180×80 | Warp Miss | 25 | 130 | 24 m | 55.7 | 355 |

| WF1 Miss (1) | 3 | 4 | ||||

| WF1 Miss (2) | 0 | 0 | ||||

| WF2 Miss (1) | 4 | 11 | ||||

| WF2 Miss (2) | 0 | 0 | ||||

| Manual Stops | 2 | 2 | ||||

| Others | 0 | 0 |

Loom No 234:

| Construction | Causes of stoppages | Times | min | Production | Efficiency % | RPM |

| 40×40 / 110×70 | Warp Miss | 21 | 160 | 33.8 m | 48.0 | 512 |

| WF1 Miss (1) | 1 | 0 | ||||

| WF1 Miss (2) | 1 | 0 | ||||

| WF2 Miss (1) | 3 | 3 | ||||

| WF2 Miss (2) | 0 | 0 | ||||

| Manual Stops | 0 | 0 | ||||

| Others | 0 | 0 |

Quality Management System:

Grey yarn test report :

Date :25-06-2010

Count:45/1 , CVC

Lot no:33/10

| Property | Cone :1 | Cone:2 | Cone:3 | Cone:4 |

| Tenacity (CN/Tex) | 18.01 | 17.95 | 18.17 | 18.34 |

| CV% of tenacity | 9.03 | 8.70 | 10.76 | 8.62 |

| Elongation (%) | 5.18 | 5.82 | 5.74 | 5.31 |

| CV% of Elongation | 11.63 | 9.99 | 10.91 | 12.18 |

| Max value | 20.84 | 22.82 | 22.54 | 21.52 |

| Min value | 14.67 | 13.91 | 14.21 | 14.04 |

Total test: 4/2000 MTR

Overall results:

Tenacity (CN/Tex ) =18.12

CV% of Tenacity =9.29

Elongation (% ) =5.51

CV % of elongation =12.13

USTER TESTER:

| Test no | Thick place (+35%) | Thick place (+50%) | Thick place (+70%) | Neps (+140%) | Neps (+200%) | Neps (+400%) | Hairiness (-) | Thin place(-30%) | Thin place(-40%) | Thin place(-50%) |

| 1/1 | 333 | 65 | 10 | 322 | 125 | 12 | 3.86 | 907 | 122 | 10 |

| 1/2 | 269 | 48 | 10 | 273 | 99 | 12 | 3.79 | 917 | 115 | 5 |

| 1/3 | 250 | 47 | 9 | 258 | 108 | 8 | 3.91 | 785 | 119 | 4 |

| 1/4 | 227 | 35 | 2 | 269 | 87 | 4 | 3.86 | 769 | 112 | 8 |

Grey yarn test report :

Date :10-06-10

Count:40/1 , cotton

Lot no:08/10

| Property | Cone :1 | Cone:2 | Cone:3 | Cone:4 |

| Tenacity (CN/Tex) | 19.90 | 19.27 | 19.42 | 19.87 |

| CV% of tenacity | 8.02 | 8.20 | 7.74 | 6.79 |

| Elongation (%) | 6.04 | 5.99 | 6.01 | 6.12 |

| CV% of Elongation | 7.02 | 7.43 | 7.11 | 6.09 |

| Max value | 23.51 | 22.95 | 22.45 | 23.20 |

| Min value | 14.85 | 14.14 | 15.86 | 17.37 |

Total test: 4/2000 MTR

Overall results:

Tenacity (CN/Tex) =19.61

CV% of Tenacity =7.77

Elongation (%) =6.04

CV % of elongation =6.92

USTER TESTER:

| Test no | Thick place (+35%) | Thick place (+50%) | Thick place (+70%) | Neps (+140%) | Neps (+200%) | Neps (+400%) | Hairiness (-) | Thin place(-30%) | Thin place(-40%) | Thin place(-50%) |

| 1/1 | 116 | 23 | 6 | 192 | 53 | 3 | 4.08 | 360 | 31 | 0 |

| 1/2 | 204 | 35 | 8 | 408 | 123 | 4 | 4.09 | 593 | 39 | 0 |

Grey yarn test report:

Date: 06-02-10

Count: 20/1 card

Lot no: 08/10

| Property | Cone :1 | Cone:2 | Cone:3 | Cone:4 |

| Tenacity (CN/Tex) | 18.53 | 18.46 | 17.50 | 18.18 |

| CV% of tenacity | 6.23 | 6.71 | 7.42 | 6.87 |

| Elongation (%) | 5.50 | 5.54 | 5.41 | 5.61 |

| CV% of Elongation | 7.91 | 5.81 | 9.64 | 6.31 |

| Max value | 20.56 | 20.84 | 22.03 | 20.84 |

| Min value | 16.54 | 15.17 | 14.05 | 15.92 |

Total test: 4/2000 MTR

Overall results:

Tenacity (CN/Tex) =18.17

CV% of Tenacity =6.80

Elongation (%) =5.51

CV % of elongation =7.59

USTER TESTER:

| Test no | Thick place (+35%) | Thick place (+50%) | Thick place (+70%) | Neps (+140%) | Neps (+200%) | Neps (+400%) | Hairiness (-) | Thin place(-30%) | Thin place(-40%) | Thin place(-50%) |

| 1/1 | 201 | 36 | 5 | 332 | 82 | 7 | 2.80 | 332 | 13 | 0 |

| 1/2 | 207 | 41 | 7 | 388 | 104 | 5 | 3.26 | 493 | 29 | 0 |

| 1/3 | 181 | 24 | 5 | 335 | 88 | 6 | 3.22 | 371 | 14 | 0 |

| 1/4 | 147 | 26 | 6 | 315 | 99 | 0 | 3.13 | 430 | 27 | 1 |

Grey yarn test report:

Date: 16-03-10

Count: 30/1, card

Lot no: 20/10

| Property | Cone :1 | Cone:2 | Cone:3 | Cone:4 |

| Tenacity (CN/Tex) | 17.18 | 17.57 | 17.12 | 17.02 |

| CV% of tenacity | 7.55 | 8.22 | 8.80 | 8.28 |

| Elongation (%) | 4.03 | 4.95 | 4.20 | 4.96 |

| CV% of Elongation | 9.34 | 9.11 | 9.06 | 9.55 |

| Max value | 19.80 | 21.81 | 19.98 | 22.04 |

| Min value | 13.84 | 13.59 | 13.73 | 13.50 |

Total test: 4/2000 MTR

Overall results:

Tenacity (CN/Tex) =17.22

CV% of Tenacity =8.21

Elongation (%) =4.53

CV % of elongation =9.26

USTER TESTER:

| Test no | Thick place (+35%) | Thick place (+50%) | Thick place (+70%) | Neps (+140%) | Neps (+200%) | Neps (+400%) | Hairiness (-) | Thin place(-30%) | Thin place(-40%) | Thin place(-50%) |

| 1/1 | 475 | 103 | 10 | 891 | 217 | 4 | 4.84 | 850 | 74 | 2 |

| 1/2 | 415 | 77 | 16 | 851 | 217 | 14 | 4.74 | 835 | 71 | 2 |

| 1/3 | 430 | 88 | 9 | 763 | 171 | 3 | 5.22 | 875 | 79 | 1 |

| 1/4 | 417 | 89 | 15 | 752 | 182 | 2 | 5.09 | 820 | 72 | 0 |

Grey yarn test report:

Date: 07-03-10

Count: 60/1 comb

Lot no: 6060c/10

| Property | Cone :1 | Cone:2 | Cone:3 | Cone:4 |

| Tenacity (CN/Tex) | 27.09 | 26.48 | 26.98 | 26.34 |

| CV% of tenacity | 8.04 | 8.78 | 8.49 | 7.61 |

| Elongation (%) | 4.43 | 4.55 | 4.40 | 4.52 |

| CV% of Elongation | 8.20 | 8.18 | 9.49 | 9.72 |

| Max value | 34.16 | 30.30 | 32.57 | 29.85 |

| Min value | 19.85 | 19.32 | 18.48 | 23.03 |

Total test: 4/2000 MTR

Overall results:

Tenacity (CN/Tex) =26.72

CV% of Tenacity =8.23

Elongation (%) =4.47

CV % of elongation =8.89

USTER TESTER:

| Test no | Thick place (+35%) | Thick place (+50%) | Thick place (+70%) | Neps (+140%) | Neps (+200%) | Neps (+400%) | Hairiness (-) | Thin place(-30%) | Thin place(-40%) | Thin place(-50%) |

| 1/1 | 150 | 8 | 1 | 226 | 35 | 1 | 2.85 | 826 | 100 | 6 |

| 1/2 | 151 | 15 | 1 | 221 | 34 | 1 | 2.19 | 774 | 93 | 8 |

| 1/3 | 132 | 12 | 1 | 248 | 49 | 0 | 2.18 | 794 | 95 | 3 |

| 1/4 | 159 | 16 | 0 | 303 | 68 | 3 | 2.91 | 947 | 168 | 7 |

Quality assurance system

Quality assurance procedure may be divided into two major parts:

- On line quality control.

- Off line quality control.

On Line Quality Control:

On line quality control is done at different stages, such as :

Winding: Soft or hard package.

Warping: Color pattern, width of repeat, section repeat.

Sizing: pick up %, size paste quality check

Weaving: Dropper check, loose warp check, reed mark, wrong denting etc.

Off Line Quality Control:

Sample collection:

One meter sample of every order is collected by online inspector . Every sample is clearly identified with a sticker.

QC department checks the fabric in the loom and at that time the loom remains stops. He ensure the quality parameter such as free of hole or spot, reed mark, repeat size, width of fabric etc.

TEST PROCEDURE

Fabric weight (G.S.M):

The procedure for fabric weight test of finished fabric:

– M/C used: G.S.M. cutter.

-Frequency: Every order.

-Procedure: 3 samples pieces are cut with G.S.M. cutter. Find their average wt.

Gram per square meter (GSM) = Average wt*100

Ounce per square meter (oz/yd2)=G.S.M.*0.0296

-Performance std: According to buyer’s given std.

-In case of non-conformity:

To increase G.S.M.: Reduce width mechanically.

To decrease G.S.M: Increase width mechanically

Width Test:

Machine used : Measuring tape.

Frequency : Every order & after every finishing process.

Procedure : Manual measurement by tape.

Overall width : Total width.

Useable width : Width without selvedge.

Pref. Std. : 150+2 cm or specified by the customer.

In case of non-conformity: Re-finish.

Tensile strength:

M/C used : Alphateus Tensile Tester.

Frequency : Every order.

Procedure : According to customers requirements.

In case of non-conformity: To increase tensile strength re-

Mercerize (increase of 5-10%) and re-finish.

Tear strength:

M/C used : Element Tearing Tester.

Manufacture : Messmer Instruments Ltd.

Frequency : Every order (only for 100% cotton light fabric).

Procedure : According to customers requirements.

In case of non-conformity: To increase tearing strength re-mercerize & re-finish.

Pilling Resistance:

M/C used : ICI Pilling box.

Manufacturer : James H. Heals.

Frequency : Whenever required.

Procedure : BS 5811(36000 rear) ASTM D 3512.

Performance std : Grade 4; Grade 3(For each fabric).

In case of non-conformity: Re-singeing followed by resin finish.

Fabric inspection:

It is the responsibility of both the textile supplier and garment manufacturer to inspect all textiles to ensure their compliance with the buyer standard. Textile which are being exported to another country for use in the assembly of a finished product are required to be inspected by the buyer’s designed inspection service prior to shipment. It is the sole responsibility of the textile supplier to ensure that the textiles are inspected prior to shipment. For textiles which are to be assembled in the country of textile origin, inspection is required only if requested by the buyer. Once requested it is the responsibility of the textile supplier to ensure that the textiles are inspected prior to shipment.

The fabric control service will be divided in the following subgroups:

A. Pre-control: “feel” examination, appearance, verification of any unpleasant odorous, colors, shades, weight, listing and ending; verification of dye uniformity between center and selvedge by means of a special fabric strip “sleeve” and dimensional checking by means of a steam test, production of the shade continuity cards.

B. Control: All textile inspections will be conducted in accordance with the 4 point system. The control consists in checking of fabrics on appropriate machines, permitting complete tension free sliding and measuring of the fabric.

The pieces will always be processed in rolls or humpback, never folded in order to avoid permanent creases in the fabric.

Tension free measuring will be carried out electronically with or without metric labeling on the selvedge and the accuracy will be guaranteed with a maximum approximation of 0.5%. Measuring will be expressed in yards.

References for pattern and finishing will be certified by a fabric swatch indicated by the Garment conductor, colors by colors chart/shade chart. This sample will be reference sample taken from the first delivery of the production or a sample taken from a sample piece. Sample dimensions will be such as to permit verification of all characteristics, pattern, colors, etc. of the fabric to be inspected.

TEXTILE SPECIFICATIONS AND EVALUATION

All textile inspections will be conducted in accordance with the Four Point System.

The Four Point System derives its name from the basic grading rules:

- No more than four penalty points may be assigned for any single defect.

- No more than four penalty points may be assigned to one linear yard, regardless of the number of defects within that one yard.

- Penalty point evaluation

Defects in both the warp/weft direction will be assigned points using the following criteria:

1 point -Defects size not exceeding 3”

2 points -Defects size exceeding 3” but not exceeding 6”

3 points -Defects size exceeding 6” but not exceeding 9”

4 points -Defects size exceeding 9”

- A continuous defect running (9”) or longer shall be assigned four points for each yard in which it occurs within the shipment.

· For continuous defects such as side to side shading, side-center-side shading, end to end shading, off shade, no penalty points shall be assigned. However, the entire roll shall be graded as “Second Quality” whole lot cannot be shipped.

The following fabric penalty point grading standards are to be used when inspecting all textiles. The standards are intended to be comprehensive; rise to occasion, whenever a specific fabric condition is mot described. When this occurs, the shipment will be aborted if the inspection was failed, and the inspection service will contact the garment contractor/supplier for disposition.

Running Defect:

- Any defects found to repeat and/ or run in a continuous manner will constitute a running defect. Any running defect will be assigned four penalty points for each yard in which the defect occurs. For a roll containing more than five continuous yards per100 linear yards with running defects, the whole roll will be graded as second quality and cannot be shipped.

Full width defects:

· Any roll that contains more than six full width defects per 100 linear yards shall be graded as second quality and cannot be shipped.

- No roll will be accepted as an A grade roll which contains a full width defect in the first or last three yards. This roll will be graded as B grade.

· No roll will be accepted as first quality where baggy cloth occurs. A roll which exhibits a noticeable degree of looseness (waviness) or tightness along either or both selvedge or ripples, puckers, folds, creases in the body of the fabric and would prevent the fabric from lying flat when being spread in a conventional manner. This roll will be graded as second quality and cannot be shipped.

Holes And Dropped Stitches

· A hole consists of two or more broken yarns and is considered to be a defect. A hole or a dropped stitch, regardless of size will be penalized maximum of 4 points.

Roll length verification:

- Any roll of less than 30 yards in length shall be graded as second quality and cannot be shipped. The roll ticket length will be verified during the inspection

Points Calculation:

Textiles are evaluated on square yard consumption. The formula used to determine the point count level of a roll of fabric is as follows:

1. Individual piece: Points per linear yard ×36”×100 square yard

Cuttable width in inches ×inspected yard

=Points for 100 square yards

Total points per linear yard × 36”×100 sqr yard

2. Average Shipment piece:

Total inspected yards × average cuttable width

=Average points per 100 square yard per shipment

· The average point value per shipment should not exceed 20 points per 100 square yards and not contain any second quality / rejected roll.

· A grade acceptance- Individual roll within 25 points per 100 square yards.

- B grade acceptance- Individual roll within 26-30 points per 100 square yards.

· Second quality /Rejected-Individual roll with in 25points per 100 square yards.

- Maximum 20% of “B” grade fabric yards are allowed with in a shipment.

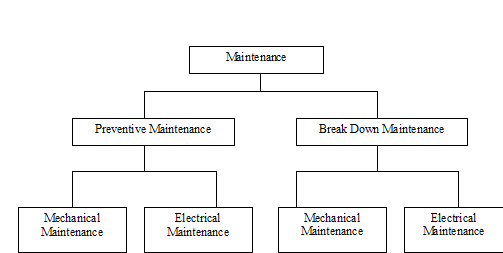

Maintenance

Maintenance is a process by which equipment is looked after in such a way that trouble free. Service and increased machine life can be ensured and specific product quality required by the customers is sustained.

On time maintenance increase m/c lifetime & ensures trouble free services.

MAINTENANCE OF MACHINERY:

Preventive Maintenance:

Preventive maintenance is a predetermined routine actively to ensure on time inspection / checking of facilities to uncover conditions that may lead to production break downs or harmful description.

Break down maintenance:

In this case, repairs are made after the equipment is out of order and it can not perform its normal functions.

Routine Maintenance:

Maintenance of different machines is prepared by expert engineer of maintenance department. Normally in case of dyeing m/c maintenance after 30 days complete checking of different important parts are done.

MAINTENANCE TOOLS & EQUIPMENTS:

- Socket/ Spanner /Impact socket sets: Suitable for driving metric/AF, BSW,BSFand BA hexagonal nut/BOH.

- Table / Drill vice: Ideal for small drilling task.

3. Screw driver: Ideal for service / repairing loss.

4. Circlip pliers: Opening & setting of circlip.

5. Pliers & cutters.

6. Centre punch: With knurnled grip & squire head with 60* gasket point . Used for well defined impression for cutting / drilling etc.

7. Pipe cutter : Used for steel conduct, copper brass or aluminium.

8. Nose pliers.

9. File set: Squire, half round, three square, round, flat.

10. Hammer: Ball point, soft faced etc.

11. Hexagon keys: Short age “L” shaped key, long arm “L” shaped.

12. Hole punch.

13. Hack-saw.

14. Adjustable wrench.

15. Single end spanner.

16. Riveters.

17. Puller.

18. Ranching ring.

19. Torque wrench.

20. Tri-squire.

21. Measuring tape.

22. Spirit level.

23. Thread gauge.

24. Deep gauge.

25. Wire gauge.

REMARKS:

Maintenance of machines is very essential to prolong the m/c life and good maintenance is important consideration.

In this industry maintenance program is done by expert maintenance team. So production is stopped due to m/c problem for a short time.

Utility Department

Generator:

Brand name : Watsila

Origin : France

System : PLC control

Capacity : 1 MW each

No of cylinder : 16

Generator type : Gas generator (1% gas: 11.5% air)

No of generator : 9

Overall efficiency : 80 %

Stand by diesel generator which capacity is 750 KW and also two gas turbine which production capacity is 9 MW used for other project in bex- tex ltd .

Maintenance:

# After 750 hours Lube oil is changed, and 40 grade oil is used for this purpose.

# Clean the spark plug after 2000 hour.

# Tappet clearance after 750 hour.

Oil category:

Company: Mobile

Name : Pagases 805

Compressor:

No. of compressor : 10

Type : Screw type rotary compressor

Oil free (6) ,oil injected (4)

Model : Atlas (oil free), Fini , ELGI .

Origin : Belgium (oil free), Italy (atlas), India

Capacity : 46.5 m3/min (6)

13.7m3/min (1)

. 9.6m3 /min (1)

6.4m3 /min (1)

14.7m3 / min (1) , total = 323.4 m3 / min

Pressure : 7.5 bar

Oil category : lube oil (mineral oil)

Speed : 1450 rpm

BOILER:

Type: Horizontal fire tube boiler

Manufacturer: Thermex

Origin: India

Fuel : Gas

Maximum pressure: 10 bar

Working pressure : 9 bar

Heating surface : 3315 square feet .

Chiller:

Brand name : Thermex

Origin : India

Capacity : 210(3) ton+500(1)ton ,total=1130 ton

System : vapor absorption system

Chemical : Hydro chem.+ steam, Lithium Bromide ,

Lithium ethanol, octail alcohol .

No of machine : 04

Humidification:

Relative humidification depends on :

Motor condition

Room temperature

Due point

Return fan.

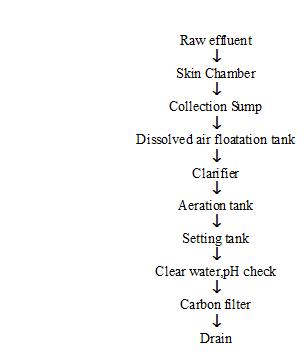

The Effluent Treatment Plant (ETP):

The effluent generated from different sections of a textile mill must be treated before they are discharged to environment. Various chemicals & physical means are introduced for this purpose. The effluent treatment plant in Beximco is chemical biological combination process developed by India.

Flowchart of effluent treatment:

Limitations of the Report:

- Because of secrecy act, the data on costing and marketing activities has not been supplied & hence this report excludes these chapters.

- We had a very limited time. In spite of our willing to study more details it was not possible to do so.

- Some of the points in different chapter are not described as these were not available.

- The whole process is not possible to bind in such a small frame as this report, hence our effort spent on summarizing them.

Conclusion:

What special in this report is that the information, data & description very much subjective & practical. So, one can easily have an idea about the whole weaving unit of BTL at a single look on it.

For the eight weeks we gave our full effort to collect the available information and tried to learn about factory management system. This industrial training program is a big boost for us to deal our professional life in the near future.

![Report on Industrial Attachment at DIVINE TEXTILE LIMITED [ Part – 2 ]](https://assignmentpoint.com/wp-content/uploads/2013/03/divine-group-128x100.jpg)