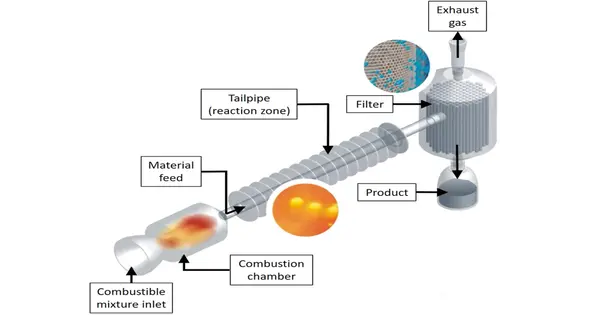

Pulsation reactor technology is a chemical reactor design that uses pulsing flow to improve mixing, heat transfer, and reaction kinetics. It is a thermal process for producing fine particles with exact characteristics. The idea is to cause oscillatory motion in the reactants by altering the flow rate, pressure, or other operating parameters within the reactor at regular intervals. This dynamic mixing action increases mass and heat transfer rates, resulting in more efficient chemical processes.

Pulsation reactor technology is a thermal technique with a unique functional concept that produces reaction parameters and a reaction medium, which eventually leads to other property parameters such as the powder material’s surface, reactivity, homogeneity and particle size.

The method has proven particularly useful for producing ceramic and submicroscale powders, as well as highly active catalysts. The pulsation reactor may also create simple oxides such as zirconium oxide with doping components, as well as mixed oxides such as spinel.

Key features and advantages of pulsation reactor technology include:

- Enhanced Mixing: Pulsating flow creates vigorous mixing within the reactor, promoting better contact between reactants and improving reaction uniformity.

- Improved Heat Transfer: The oscillatory motion enhances heat transfer rates between the reactants and the reactor walls, enabling better temperature control and reducing hot spots.

- Increased Reaction Rates: Enhanced mixing and heat transfer lead to accelerated reaction kinetics, allowing for faster reaction rates and potentially shorter residence times in the reactor.

- Scalability: Pulsation reactor technology can be adapted to various scales, from laboratory setups to industrial-scale reactors, making it suitable for a wide range of applications.

- Energy Efficiency: The pulsating flow can reduce energy consumption compared to conventional reactor designs by optimizing mixing and heat transfer without the need for excessive agitation or external heating.

Applications

Pulsation reactor technology has a wide range of applications in industries such as chemical synthesis, pharmaceutical manufacture, petroleum refining, and environmental engineering. It is especially beneficial for reactions with slow kinetics, sensitive reactions that require careful control of reaction conditions, and processes in which heat transfer limits affect overall performance.

Overall, pulsation reactor technology provides a novel way to increasing reactor performance and efficiency, making it an appealing choice for chemical engineers and researchers looking to optimise chemical processes.