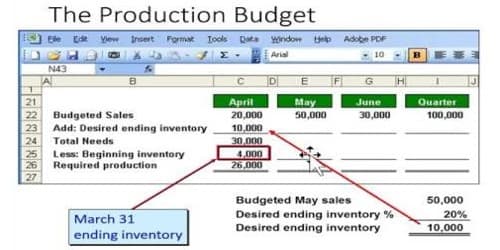

Production Budget

For manufacturing companies production budget is prepared prior to the sales budget. The production budget contains details of the number of units that are intended to be produced by a business in a particular period. This budget shows the quantities to be produced for achieving sales targets and keeping sufficient inventories. A production budget is stated in physical units. In other words, this is a report that estimates the number of units that a plant will produce from period to period. It helps a company to plan its manufacturing schedule and ensure that it produces an adequate quantity of goods. This budget is typically prepared for a “push” manufacturing system, as is used in a material requirements planning environment.

The required production is determined by subtracting the beginning finished goods inventory from the sum of expected sales and planned to end inventory of the period. Thus:

Budgeted production volume = Budget sales units + Closing Inventory – Opening stock

OR,

Budgeted sales volume + desired closing inventory – opening inventory

It can be very difficult to create a comprehensive production budget that incorporates a forecast for every variation on a product that a company sells, so it is customary to aggregate the forecast information into broad categories of products that have similar characteristics.

Managers use this budget to estimate how many units they will need to produce in future periods based on the future estimated sales numbers. This production is based on budgeted sales volume and desired inventory level. The responsibility for the preparation and operation of production budget lies with the production manager. It allows a company to plan its manufacturing activity. It is prepared after taking the sales budget into account as well as the opening and closing inventory.

There are three parts to the production budget: direct materials purchases budget, direct labor budget, and overhead budget.

Information Source: