A portion of an old car that is converted to graphene could be repurposed as a superior part for a new vehicle. Rice University chemists are using the university’s flash Joule heating technology to convert plastic parts from “end-of-life” vehicles into graphene in collaboration with Ford Motor Company experts.

The average SUV includes up to 350 kilograms (771 pounds) of plastic, which would otherwise end up in a landfill for decades if not for a recycling method described in the first edition of a new Nature journal called Communications Engineering.

The project’s goal, led by Rice chemist James Tour and graduate student and lead author Kevin Wyss, was to reuse the graphene in order to create better polyurethane foam for future automobiles. The graphene-infused foam had a 34% boost in tensile strength and a 25% improvement in low-frequency noise absorption, according to tests.

That’s with only 0.1 percent graphene by weight or less. When the new car is no longer needed, the foam can be flashed back into graphene.

“Ford sent us 10 pounds of mixed plastic waste from a vehicle shredding facility,” Tour said. “It was muddy and wet. We flashed it, we sent the graphene back to Ford, they put it into new foam composites and it did everything it was supposed to do.”

“Then they sent us the new composites and we flashed those and turned them back into graphene,” he said. “It’s a great example of circular recycling.”

According to the experts, the amount of plastic used in automobiles has climbed by 75% in just six years as a means of reducing weight and improving fuel economy.

Segregating mixed end-of-life plastic by type for recycling has been a long-standing issue for the auto industry, according to Tour, and it’s becoming more critical as end-of-life vehicle regulations become more stringent.

“In Europe, cars come back to the manufacturer, which is allowed to landfill only 5% of a vehicle,” he said. “That means they must recycle 95%, and it’s just overwhelming to them.”

We have hundreds of different combinations of plastic resin, filler, and reinforcements on vehicles that make the materials impossible to separate. Every application has a specific loading/mixture that most economically meets the requirements.

Deborah Mielewski

According to co-author Deborah Mielewski, technical fellow for sustainability at Ford, much of the combined plastic ends up being burnt. The United States shreds 10 to 15 million automobiles per year, with more than 27 million shredded globally.

“We have hundreds of different combinations of plastic resin, filler, and reinforcements on vehicles that make the materials impossible to separate,” she said. “Every application has a specific loading/mixture that most economically meets the requirements.”

“These aren’t recyclables like plastic bottles, so they can’t melt and reshape them,” Tour said. “So, when Ford researchers spotted our paper on flash Joule heating plastic into graphene, they reached out.”

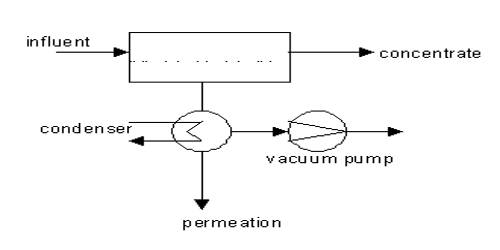

The Tour lab introduced flash Joule heating to create graphene in 2020, which inserts ground plastic and a cokeadditive (for conductivity) between electrodes in a tube and blasts it with high voltage. Other elements are vaporized by the quick, high heat, which reaches over 5,000 degrees Fahrenheit, leaving behind easy-to-solubilize turbostratic graphene.

Because the procedure does not require solvents and utilizes very little energy to make graphene, flash heating has considerable environmental benefits.

The Rice lab ground shredder “fluff” made of plastic bumpers, gaskets, carpets, mats, seating, and door casings from end-of-life F-150 pickup trucks to a fine powder without cleaning or pre-sorting the components to see if end-of-life, jumbled plastic might be changed.

In a heater Wyss custom developed for the experiment, the scientists flashed the powder in two steps, first with low current and then with high current.

A highly carbonized plastic was created by heating powder for 10 to 16 seconds in low current, accounting for around 30% of the initial mass. The remaining 70% was released into the atmosphere or collected as hydrocarbon-rich waxes and oils, which Wyss thought could be recycled.

After that, the carbonized plastic was exposed to high-current flashing, which converted 85 percent of it into graphene while also releasing hydrogen, oxygen, chlorine, silicon, and trace metal contaminants.

Wyss was also attracted by the opportunity to incorporate life-cycle analysis (LCA) into a Rice research project. “I’m driven by sustainability, and it’s where I want to focus in my career,” he said.

The LCA entailed comparing graphene obtained from flashing automobile parts to graphene made from other means and assessing recycling effectiveness. When compared to previous methods, they found that flash Joule heating produced graphene with a significant reduction in energy, greenhouse gas emissions, and water use, even after accounting for the energy required to reduce the plastic shredder fluff to powder.

According to co-author Alper Kiziltas, a technical expert at Ford Research who focuses on sustainability and new materials, Ford has been employing up to 60 pounds of polyurethane foam in its vehicles since 2018, with roughly 2 pounds of it being graphene-reinforced.

“When we got the graphene back from Rice, we incorporated it into our foam in very small quantities and saw significant improvement,” he said. “It exceeded our expectations in providing both excellent mechanical and physical properties for our applications.”

Graphene has a bright future at Ford. It was first used in a number of other under-the-hood components, and then a graphene-reinforced engine cover was added in 2020. It will also be used to reinforce strong plastics, according to Kiziltas.

“Our collaborative discovery with Rice will become even more relevant as Ford transitions to electric vehicles,” Mielewski said. “When you take away the noise generated by the internal combustion engine, you can hear everything else in and outside the vehicle that much more clearly.”

“It’s much more critical to be able to mitigate noise,” she said. “So we desperately need foam materials that are better noise and vibration absorbers. This is exactly where graphene can provide amazing noise mitigation using extremely low levels.”

Other co-authors of the paper are Robert DeKleine and Rachel Couvreur of Ford. Tour is the T.T. and W.F. Chao Chair in Chemistry and a professor of materials science and nanoengineering. The Air Force Office of Scientific Research (FA9550-19-1-0296), the Department of Energy National Energy Technology Laboratory (DE-FE0031794), and a National Science Foundation Graduate Research Fellowship supported the research.