Palmitic Acid

Definition

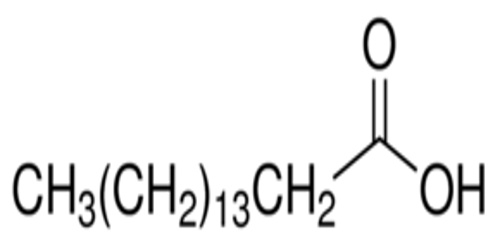

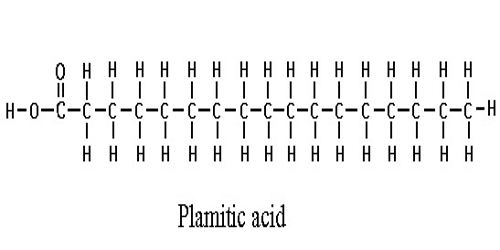

Palmitic acid is a saturated fatty acid occurring as combustible white crystals in many natural oils (such as spermaceti and palm oil) and fats. Palmitic acid is most commonly produced from palm oil, although it is found in smaller amounts in other vegetable oils as well as dairy and meat. To produce pure palmitic acid, the oil is boiled to break the fatty acids off of the glycerol and then the different acids are separated out based on their boiling point. Its chemical formula: C16H32O2. It is used in making soaps.

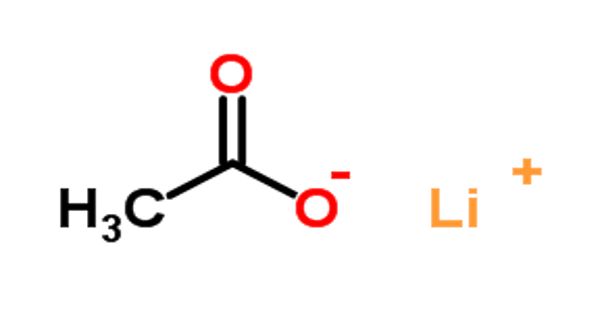

Palmitic acid can also be found in meats, cheeses, butter, and dairy products. Palmitate is the salts and esters of palmitic acid. The palmitate anion is the observed form of palmitic acid at physiologic pH (7.4). In skin care products it is commonly used in the form of an alkali salt, where the fatty acid has been reacted with an alkali like sodium hydroxide to produce sodium palmitate.

Structure, Occurrences and Properties of Palmitic Acid

Palmitic acid is a saturated fatty acid (no double bond so in shorthand 16:0) member of the sub-group called long chain fatty acids (LCFA), from 14 to 18 carbon atoms.

It is the first fatty acid produced during fatty acid synthesis in humans and the fatty acid from which longer fatty acids can be produced.

Palmitic acid was discovered by Edmond Frémy in 1840, in saponified palm oil.[10] This remains the primary industrial route for its production, with the triglycerides (fats) in palm oil being hydrolysed by high temperature water (above 200 °C or 390 °F), and the resulting mixture fractionally distilled to give the pure product.

As a consequence, palmitic acid is a major body component of animals. In humans, one analysis found it to make up 21–30% (molar) of human depot fat, and it is a major, but highly variable, lipid component of human breast milk. Palmitate negatively feeds back on acetyl-CoA carboxylase (ACC), which is responsible for converting acetyl-CoA to malonyl-CoA, which in turn is used to add to the growing acyl chain, thus preventing further palmitate generation

One of the main functions of palmitic acid alkali salts is that they acts as emulsifiers and surfactants, allowing oil based, hydrophobic molecules to interact with water where normally they would repel each other. This works by the fatty acid end of the salt interacting with the oil while the salt end interacts with the water creating an adapter between oil and water. In some products this increases the stability of the product as oil and water would naturally separate without it. In soaps and cleansing oils, the fatty end grabs oil and water-resistant make up on your skin while the salt end then lets water wash everything off.

Applications and Effets of Palmitic Acid

Palmitic acid is used to produce soaps, cosmetics, and industrial mold release agents. These applications use sodium palmitate, which is commonly obtained by saponification of palm oil. To this end, palm oil, rendered from palm tree (species Elaeis guineensis), is treated with sodium hydroxide, which causes hydrolysis of the ester groups, yielding glycerol and sodium palmitate. Hydrogenation of palmitic acid yields cetyl alcohol, which is used to produce detergents and cosmetics

Topical palmitic acid is not known to cause side effects. A diet containing large amounts of palmitic acid can increase risk of heart disease but topical application doesn’t contribute to this.

Palmitic acid strongly boosts metastasis in mouse models of human oral cancer cells. Among all fatty acids, it has the strongest effect in boosting the metastatic potential of CD36+ metastasis-initiating cells.

Reference: