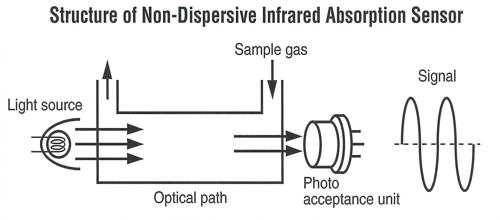

A nondispersive infrared sensor (NDIR sensor) is a simple spectroscopic sensor often used as a gas detector. It is non-dispersive in the fact that no dispersive element is used to separate out the broadband light into a narrow spectrum suitable for gas sensing. NDIR spectroscopy is often used to detect gas and measure the concentration of carbon oxides (for example, carbon monoxide and carbon dioxide). The majority of NDIR sensors use a broadband lamp source and an optical filter to select a narrow band spectral region that overlaps with the absorption region of the gas of interest. This measurement is then used to calculate the concentration of a specific gas.

NDIR is an industry term for “nondispersive infrared”, and is the most common type of sensor used to measure carbon dioxide or CO2. Infrared (IR) techniques are very popular in gas detection technology since many gases have characteristic vibration/rotation absorption spectra with narrow, non-overlapping bands in the infrared spectrum between 2 μm and 20 μm. Non-dispersive type infrared absorption sensors are widely used for various types of gas measurements such as carbon monoxide (CO), carbon dioxide (CO2), and hydrocarbons (HC).

Principle

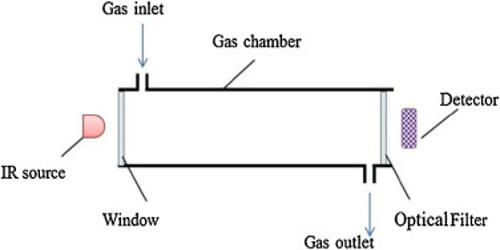

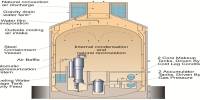

The principle of non-dispersive infrared absorption uses the properties of individual gases in absorbing specific frequencies of infrared light which the sample gas is exposed to. The main components of an NDIR sensor are an infrared (IR) source (lamp), a sample chamber or light tube, a light filter, and an infrared detector. An infrared beam passes through the sampling chamber, and each gas component in the sample absorbs some particular frequency of infrared. The IR light is directed through the sample chamber towards the detector. In parallel, there is another chamber with an enclosed reference gas, typically nitrogen. The gas in the sample chamber causes absorption of specific wavelengths according to the Beer-Lambert law, and the attenuation of these wavelengths is measured by the detector to determine the gas concentration. The detector has an optical filter in front of it that eliminates all light except the wavelength that the selected gas molecules can absorb.

The IR signal from the source is usually chopped or modulated so that thermal background signals can be offset from the desired signal. Today’s newest generation of CO2 sensors has even more optimized waveguides, allowing a longer optical light path to be folded into an even smaller 8 mm x 33 mm x 20 mm footprint.

Non-Dispersive Infra-Red (NDIR) detectors are the industry-standard method of measuring the concentration of carbon oxides (CO & CO2). NDIR sensors are based on infrared spectroscopy, the principle that molecules absorb specific light frequencies that are characteristic of their structure. NDIR sensors for carbon dioxide are often encountered in heating, ventilation, and air conditioning (HVAC) units. In the NDIR application, pulsed and filtered IR light is applied to the series-connected active junctions; the junctions are therefore heated, which in turn generates a small thermoelectric voltage.