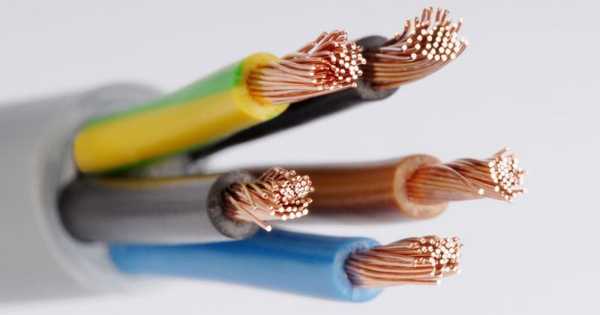

Our electrical infrastructure has largely remained unchanged since World War II, but advances in technology, particularly in materials, have opened doors that we would never have imagined possible in the past. These advancements have laid the groundwork for reimagining our electrical infrastructure for the next 100 years and beyond.

Researchers are looking into new materials for electrical insulation, or packaging, that can remove heat more effectively than current insulation, as we need to redesign our electrical infrastructure for the next 100 years and beyond to keep up with advanced technology.

Our electrical infrastructure has largely remained unchanged since World War II, but advances in technology, particularly in materials, have opened doors that we would never have imagined possible in the past. These advancements have laid the groundwork for reimagining our electrical infrastructure for the next 100 years and beyond.

The redesign is critical because we are putting more strain on the electrical grid every day, demanding faster computer processing, and moving toward electric transportation. The advanced and miniaturized semiconductors that power these devices and infrastructure generate a lot of heat, which can cause them to fail. These devices must also be electrically isolated and weatherproofed.

Researchers are analyzing new materials for electrical insulation, or packaging, that can remove heat more effectively compared to today’s insulation, amid a need to redesign our electrical infrastructure for the next many years to match advanced technology.

New types of electrical insulation are being developed around the world to meet ever-increasing performance and reliability demands as devices and infrastructure continue to advance. Researchers at The University of Texas at Austin are working with the United States Army Research Lab to develop new materials for electrical insulation, or packaging, that can remove heat more effectively than current insulation.

“An electrical grid serves millions of homes and businesses and handles thousands of amps of current,” said Vaibhav Bahadur, associate professor of thermal fluids systems in the Cockrell School of Engineering’s Walker Department of Mechanical Engineering and co-author of a new paper published in Proceedings of the IEEE. “We’re talking about significant heat generation, high voltages, and the ability to withstand extreme temperatures, which will only worsen as the climate changes.”

“The main issue we’ve identified is that simply improving thermal conductivity isn’t enough,” Bahadur explained. “To meet electrical, thermal, and mechanical requirements, you need a more holistic understanding of materials and multifunctional materials.”

Concentrating on a single property, such as thermal conductivity, is insufficient to obtain the necessary performance and lifespan from electronic devices. You must ensure that materials have high electrical resistance, tolerance to extreme temperatures, the ability to withstand mechanical stress, and moisture resistance, among other characteristics. The grand challenge for material developers is to improve all of these properties at the same time, rather than one at a time as is currently done.

“A comprehensive assessment of these new nanomaterials has never been done before,” said Robert Hebner, Walker Department research professor, director of the UT Center for Electromechanics, and paper co-author. “This article serves as a road map for the creation of future materials. From an engineering and reliability standpoint, we provide a critical review and perspectives to the materials community.”

These new nanocomposite materials are made of polymers with nanoparticles in them and aim to achieve thermal performance levels comparable to metals while retaining the benefits of polymers such as lightweight, corrosion resistance, and ease of fabrication. The thermal conductivity of some of the most promising materials is close to 100 times that of conventional polymers.

Researchers believe that if we can advance electrical insulation in a holistic manner, we will see improvements in many aspects of our lives. A dependable power grid based on renewables. Laptop processors that are faster and do not overheat. Air is used to cool power plants instead of scarce water resources. Even a switch to electric aviation with cables capable of withstanding the extreme heat generated during takeoff.

Given the global interest in these materials for a variety of applications, future progress can and should be rapid. According to Bahadur, the practical deployment of such advanced, multifunctional materials technology could occur as early as 2030.