A variable-frequency transformer (VFT) transmits electricity between two (asynchronous or synchronous) alternating current frequency domains. A Variable-Speed Drive (VSD) or Adjustable-Frequency Drive (AFD) is a type of power conversion device that controls the speed of an alternating current (AC) electric motor by adjusting the frequency and voltage of the power supplied to it.

The VFT is a relatively new development. Most asynchronous grid interconnections use high-voltage direct current converters, whereas synchronous grid interconnections are connected by lines and “ordinary” transformers, but without the ability to control power flow between the systems, or with a phase-shifting transformer that allows for flow control. It is commonly used in applications where precise control of motor speed is required, such as in industrial processes, HVAC systems, and renewable energy generation.

Here’s how it generally works:

- Input Stage: The VFT takes in AC power from the mains or grid. This power is typically at a fixed frequency (e.g., 50 Hz or 60 Hz in many countries).

- Rectification: The AC power is converted to DC power using diodes or thyristors in a rectifier stage. This DC power is then used to feed the next stage.

- Inverter Stage: In this stage, the DC power is converted back to AC power of variable frequency and voltage using power electronics such as insulated-gate bipolar transistors (IGBTs) or metal-oxide-semiconductor field-effect transistors (MOSFETs). By varying the switching frequency of these devices, the output frequency and voltage can be controlled.

- Control System: A control system governs the operation of the VFT. It receives input signals, such as desired motor speed or torque, and adjusts the frequency and voltage output accordingly.

- Output to Motor: The adjusted AC power is supplied to the motor, allowing precise control of its speed and torque.

VFTs offer several advantages:

- Energy Efficiency: By adjusting the motor speed to match the load requirements, VFTs can significantly reduce energy consumption compared to fixed-speed motor systems.

- Precise Control: VFTs allow for precise control of motor speed and torque, enabling optimization of industrial processes and equipment.

- Soft Starting: VFTs can provide soft starting and stopping for motors, minimizing mechanical stress and prolonging equipment lifespan.

- Regenerative Braking: In rare cases, VFTs can operate in reverse, converting mechanical energy from the motor into electrical energy that can be supplied back into the grid or used elsewhere in the system.

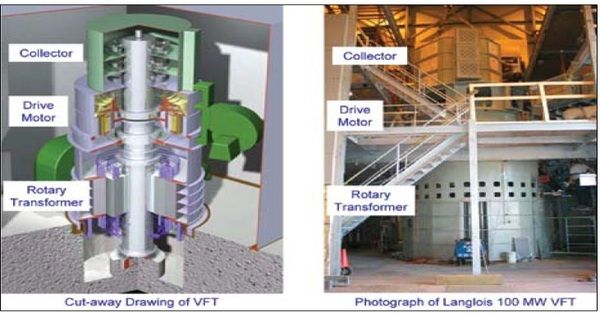

Overall, variable-frequency transformers play an important role in modern industrial and commercial applications that require efficient and precise regulation of motor speed. It can be viewed of as an extremely high power synchro, or a rotary converter operating as a frequency changer, that is more efficient than a motor-generator of the same size.