Typically, catalytic reactions are examined by observing which chemicals enter and which exit a chemical reactor. However, it turns out that much more information is required to properly understand and optimize catalysts. Scientists developed methods to observe catalytic reactions under the microscope with micrometer resolution and the process is far more complex than previously thought.

Catalysts made of tiny metal particles are used in many areas of technology, from fuel cells to the production of synthetic fuels for energy storage. However, the precise behavior of catalysts is dependent on many fine details, and their interplay is frequently difficult to understand. Even when preparing exactly the same catalyst twice, it often occurs that these two will differ in minute aspects and therefore behave very different chemically.

Scientists at TU Wien are attempting to identify the causes of such effects by imaging the catalytic reactions occurring in various locations on these catalysts using a variety of microscopy techniques. This method produces a dependable, microscopically correct understanding of the catalytic processes.

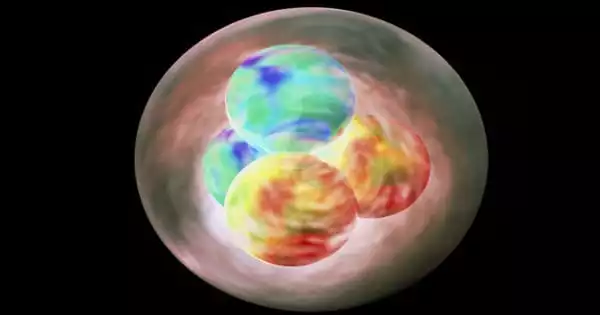

As a result, even relatively “simple” catalytic systems appeared to be more complex than expected. For example, the catalytic properties are defined by more than just the size of the metal particles used or the chemical nature of the support material. On the micrometer scale, different scenarios can exist within a single metal particle. The behavior of various catalysts could then be explained and correctly predicted using numeric simulations.

We can determine whether the catalyst is catalytically active, its chemical composition, and its electronic properties using our microscopes, and this for each and every individual spot on the sample.

Dr. Philipp Winkler

Not all particles are the same

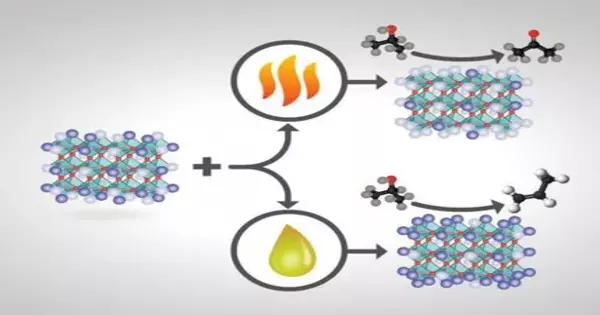

“We use rhodium particles as catalysts to investigate the combustion of the potential future energy carrier hydrogen with oxygen, forming pure water,” explains Prof. Günther Rupprechter of the Institute of Materials Chemistry at TU Wien. Several parameters are important in this process: How big are the rhodium particles individually? What type of support material do they bind to? What temperatures and pressures of reactants are involved in the reaction?

“The catalyst is made of supported rhodium particles, but it does not behave like a uniform object that can be described by a few simple parameters,” says Günther Rupprechter. “It quickly became clear that catalytic behavior varies greatly at different catalyst locations.” A specific area on a rhodium particle may be catalytically active, while another just micrometers away may be catalytically inactive. And the situation may have even flipped a few minutes later.”

Nine catalysts at one sweep

Dr. Philipp Winkler, the first author of the study, which was published in the journal ACS Catalysis, prepared a stunning catalyst sample for the experiments, which included nine different catalysts with varying metal particle sizes and support materials. All catalysts could thus be observed and compared simultaneously in a single experiment using a dedicated apparatus.

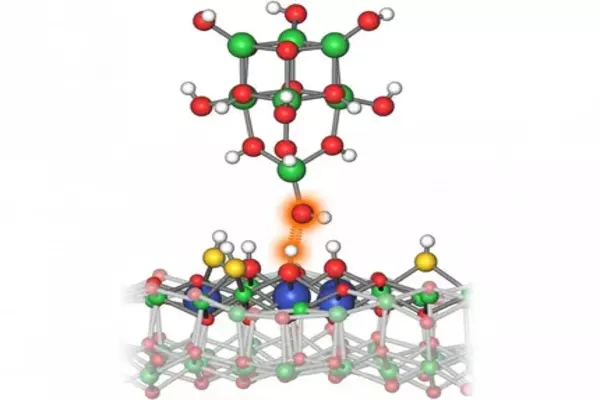

“We can determine whether the catalyst is catalytically active, its chemical composition, and its electronic properties using our microscopes, and this for each and every individual spot on the sample,” says Philipp Winkler. “Traditional methods, on the other hand, typically measure an average value for the entire sample.” However, as we have shown, this is frequently insufficient.”

Even more complex than anticipated

Chemical analysis at the microscopic level revealed that the catalyst composition can vary locally even more than expected: strong differences were observed even within individual metal particles. “Atoms of the support material can migrate onto or within the particles, or even form surface alloys,” Günther Rupprechter explains. “At some point, there is no longer a clear boundary between catalyst particle and support material, but rather a continuous transition.” This is an important consideration because it affects chemical activity.”

In a next step, the team at TU Wien will apply the gained insights and the successful methods to tackle even more complex catalytic processes, in their continuing mission to explain processes on a microscopic scale, to contribute to the development of improved catalysts, and to search for new catalysts.