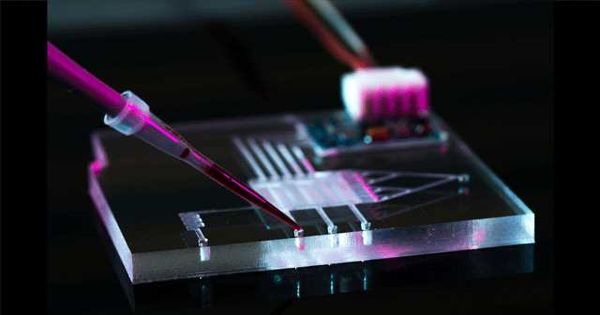

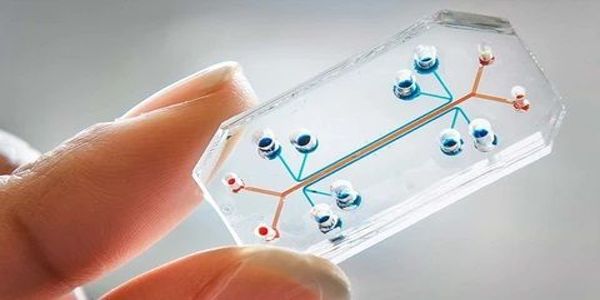

Microfluidics has been an active research field and an indispensable tool for quantitative analyses of chemicals and biological specimens for decades. Microfluidics refers to the behavior, precise control, and manipulation of fluids that are geometrically constrained to a small scale (typically sub-millimeter) at which surface forces dominate volumetric forces. This technology offers a growing set of tools for manipulating small volumes of fluids to control chemical, biological, and physical processes that are relevant to sensing.

Microfluidic techniques are emerging as cost-efficient and disposable tools for rapid diagnosis of viral infection. It is a multidisciplinary field that involves engineering, physics, chemistry, biochemistry, nanotechnology, and biotechnology. Its widespread application stems from its ability to accurately handle small quantities of samples and its well-controlled environments. It has practical applications in the design of systems that process low volumes of fluids to achieve multiplexing, automation, and high-throughput screening.

Microfluidics is the study of systems that can process small quantities of fluids by using tiny channels having dimensions at the microscale – typically tens to hundreds of micrometers.

These techniques have been widely explored for their ability to form a variety of microgel constructs. Microfluidics emerged at the beginning of the 1980s and is used in the development of inkjet printheads, DNA chips, lab-on-a-chip technology, micro-propulsion, and micro-thermal technologies. It deals with the behavior, control, and manipulation of fluids geometrically restricted to sub-millimeter dimensions, involving the integration of fluids with micro – and nano-structures and devices.

Typically, micro means one of the following features:

- Small volumes (μL, nL, pL, fL)

- Small size

- Low energy consumption

- Microdomain effects

Microfluidic systems are developed using a simple technique called photolithography, which was originally developed for creating small features on circuits in the semiconductor industry. Typically microfluidic systems transport, mix, separate, or otherwise process fluids. Various applications rely on passive fluid control using capillary forces, in the form of capillary flow modifying elements, akin to flow resistors and flow accelerators. Photolithography is the process used to transfer geometric shapes present on a mask to the surface of a suitable substrate. In some applications, external actuation means are additionally used for a directed transport of the media. It makes use of special polymers that react to specific wavelengths of light to create the desired geometric patterns on a substrate. Examples are rotary drives applying centrifugal forces for the fluid transport on the passive chips.

Advantages of microfluidic systems –

- Use of miniscule amounts of samples and reagents in the lab

- Cost reduction due to lesser use of expensive reagents

- High resolution and sensitivity in the detection and separation of molecules

- Shorter analysis times and faster results.

Active microfluidics refers to the defined manipulation of the working fluid by active (micro) components such as micropumps or microvalves. Microfluidic systems are widely used in procedures such as capillary electrophoresis, isoelectric focusing, immunoassays, flow cytometry, sample injection in mass spectrometry, PCR amplification, DNA analysis, separation and manipulation of cells, and cell patterning.

Information Source: