As a photosynthetic autotrophic organism, microalgae contain a variety of bioactive compounds such as lipids, proteins, and polysaccharides, which have been used in the food, medicine, and fuel industries, among others. Because of their high content in unsaturated fatty acid (UFA), microalgae are considered a good source of marine lipids and can be used as a supplement/replacement for fish-based oil.

The high concentration of docosahexaenoic and eicosapentaenoic acids (DHA and EPA) in microalgae lipids results in important physiological functions such as antibacterial, anti-inflammatory, and immune regulation, which is also required for its development and application.

To save the world’s fish stocks and oceans, scientists are racing to find better and sustainable ways to make healthy nutritional products such as Omega-3 fatty acids, biodiesel, aquaculture and livestock food from fast-growing microalgae.

Flinders University researchers have discovered a simple, low-cost, and effective method for extracting high-value bioactives from single-cell algae oil using waste sulfur from industries such as petrochemical production.

In this study, we build on our body of work in sulfur chemistry to find an innovative way to process triglycerides from lipid-rich microalgae. The algae oil in this case is reacted with sulfur. Polyunsaturated triglycerides combine to form polymers with numerous established applications, including environmental remediation.

Professor Justin Chalker

The innovative algae oil production process, described in the international journal ACS Sustainable Chemistry & Engineering, outlines a new method of producing enriched saturated triglycerides from sustainably produced algae oil using waste sulfur.

The process employs a single reaction to simultaneously produce valuable polymers from polyunsaturated triglycerides and enrich saturated triglycerides for various value-added applications. The sulfur reaction can extract up to 90% of the unsaturated triglycerides from cultured single-cell algae.

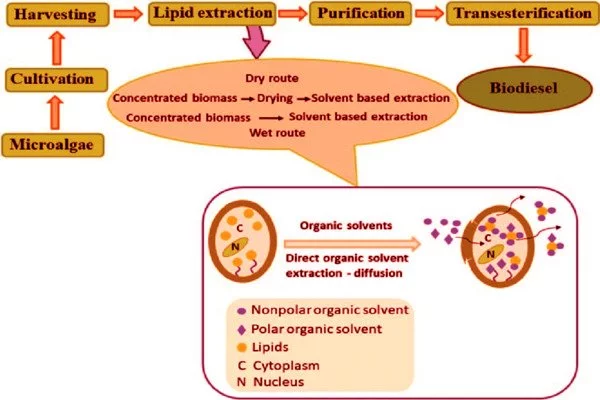

Microalgae has been proposed as a multiproduct biorefinery feedstock. The concept of an algae-based biorefinery is based on optimizing the entire process, from biomass production to processing and product generation. Microalgae contain a large number of biocompounds that have numerous applications. Several researchers have noted that one of the major process constraints in microalgae biorefineries is an efficient and cost-effective extraction process.

“In this study, we build on our body of work in sulfur chemistry to find an innovative way to process triglycerides from lipid-rich microalgae,” says Professor Justin Chalker, whose organic polymers have been used in environmental remediation, slow-release fertilizer, insulation, and e-waste.

“The algae oil in this case is reacted with sulfur. Polyunsaturated triglycerides combine to form polymers with numerous established applications, including environmental remediation. In this process, the saturated triglycerides are left unreacted for recovery and eventual conversion to value-added substances like biodiesel” Professor Chalker explains.

Extraction and separation of lipids and nutraceuticals from microalgae using traditional solvents has been widely used over the years. However, these methods of production typically necessitate the use of costly and toxic solvents. We chose ethanol (EtOH) and cyclopentyl methyl ether (CPME) for extracting bio-oil and lipids from algae based on our studies involving the use of eco-sustainable methodologies and alternative solvents.

Flinders University’s Bioprocessing Lab in Medical Biotechnology Associate Professor Munish Puri has been working on single-cell oils to create new materials suitable for nutritional supplements, animal-free meats, biodiesel, and other products.

“There is growing interest in the bio-based production of lipids from algae,” says Professor Puri, who has a background in industrial biotechnology and is leading the precision fermentation platform for producing such oils.

Energy security has become a major global concern, and much research is being conducted to find economically viable and environmentally friendly alternatives. Renewable energy appears to be the only solution that appears to meet future needs. Although various forms of renewable energy are currently used, the prospects of producing carbon-neutral biofuels from microalgae appear promising due to their unique characteristics such as the ability to grow in open ponds required for commodity product production, high CO2-sequestering capability, ability to grow in wastewater/seawater/brackish water, and high lipid productivity.