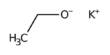

A magnetorheological fluid (MR fluid, or MRF) is a type of smart fluid in a carrier fluid, typically oil. MR is a type of smart fluid that changes its rheological properties in response to a magnetic field. When exposed to a magnetic field, the fluid’s apparent viscosity increases dramatically, to the point where it becomes a viscoelastic solid. It’s made up of tiny magnetic particles suspended in a carrier fluid, which is usually oil or water.

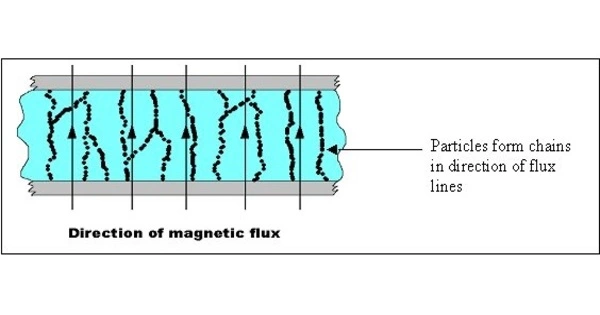

Importantly, the yield stress of the fluid in its active (“on”) state can be precisely controlled by varying the magnetic field intensity. When the fluid is subjected to a magnetic field, the particles align with the field and form chain-like structures, causing the fluid to become more viscous and solid-like. As a result, the fluid’s ability to transmit force can be controlled using an electromagnet, opening up a plethora of control-based applications.

MR fluid differs from ferrofluid in that it contains smaller particles. Micrometre-scale MR fluid particles are too dense for Brownian motion to keep them suspended (in the lower-density carrier fluid). Under normal conditions, ferrofluid particles are primarily nanoparticles suspended by Brownian motion and will not settle. As a result, these two fluids serve very different purposes.

The strength and orientation of the magnetic field govern the behavior of magnetorheological fluid. When the magnetic field is removed or reduced, the particles lose their alignment, and the fluid returns to its original low-viscosity state, behaving normally. This ability to change from a liquid to a solid-like state in milliseconds makes MR fluid useful in various engineering applications.

Application

Dampers and shock absorbers are two of the most common applications for magnetorheological fluid. The damping characteristics of a vehicle can be rapidly adjusted in response to changing road conditions or driver inputs by incorporating MR fluid into the suspension system. When a magnetic field is applied, the MR-fluid becomes more viscous, increasing damping and improving vehicle stability. When the magnetic field is removed, the fluid returns to its low-viscosity state, making the ride more comfortable.

Haptic devices, such as robotic systems and virtual reality interfaces, also make use of MR fluid. The stiffness and damping properties of the fluid can be modulated by controlling the magnetic field, allowing users to feel different textures, forces, or resistance in their interactions with the device.

MR fluid has also been used in clutches and brakes, shock isolation systems, prosthetic devices, and vibration control systems. It’s versatility and quick response time make it an appealing choice in a variety of fields where precise mechanical property control is required. It is worth noting that, because my knowledge cutoff date is September 2021, there may have been advancements or new applications of magnetorheological fluid since then.