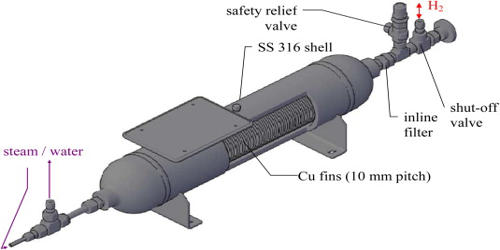

A hydride compressor is a hydrogen compressor based on metal hydrides with the absorption of hydrogen at low pressure and desorption of hydrogen at high pressure by raising the temperature with an external heat source like a heated waterbed or electric coil. Metal hydride (MH) thermal sorption compression is an efficient and reliable method allowing the conversion of energy from heat into compressed hydrogen gas.

The advantages of the hydride compressor are the high volumetric density, no moving parts, and reversible adsorption/ desorption, disadvantages are the high cost of the metal hydride and weight. The most important component of such a thermal engine – the metal hydride material itself – should possess several material features in order to achieve efficient performance in the hydrogen compression.

Metal hydride hydrogen compression method utilizes a reversible heat-driven interaction of hydride-forming metal alloy or intermetallic compound with hydrogen gas to form the corresponding metal hydride and is considered as a very promising application for hydrogen energy systems. Hydrogen is one of the highest energy-dense fuels known to man. For the majority of the practical applications, it needs to be used either in the gas or liquid form. Low-pressure hydrogen storage would require very large storage tanks or cylinders, which is not feasible for commercial use or commercial product development. Hence, it is desired to pressurize and store the hydrogen gas inside another medium (metal hydride, carbon composite tanks, etc.) prior to its usage. Usually, low-pressure hydrogen is charged into the metal alloy or intermetallic compound at very low pressures (1-10 bars) at ambient to cold temperatures.

Hydrogen gas can be compressed to higher pressures with various equipment/hardware such as reciprocating piston hydrogen compressors, ionic liquid piston hydrogen compressors, piston-metal diaphragm hydrogen compressors, guided rotor hydrogen compressors, linear hydrogen compressors, hydride hydrogen compressors, and electrochemical hydrogen compressors.

Some of the applications that can benefit from this technology are the followings:

- Chemical processing plants,

- Hydrogen purification,

- Hydrogen filling station (for transportation applications),

- Heat pumps,

- Hydrogen storage, and etc.

History

The first applications of metal hydrides were made by NASA to demonstrate long-term hydrogen storage for use in space propulsion. In the 1970s, automobiles, vans, and forklifts were demonstrated. The metal hydrides were used for hydrogen storage, separation, and refrigeration. An example of current use is hydrogen sorption cryocoolers and portable metal hydride compressors.