An ignition coil is an essential part of an internal combustion engine’s ignition system. It is used in the ignition system of a spark-ignition engine to convert the battery voltage to the much higher voltages required to power the spark plug(s). Its principal duty is to convert the low-voltage power from the battery to the high-voltage electricity required to ignite the fuel-air combination in the engine’s cylinders. The spark plugs then use the high-voltage electricity to ignite the air-fuel mixture.

The ignition coil consists of two sets of coils twisted around an iron core. Older engines frequently employ a single ignition coil with its output routed to each cylinder by a distributor, a design that is still used by many small engines (including lawnmower engines). This process is necessary for the engine to start and run properly. Modern automotive engines frequently use a distributor-less system (such as coil-on-plug), in which each cylinder has its own ignition coils. Diesel engines employ compression ignition and so do not require ignition coils.

Here’s how an ignition coil works:

- Battery Voltage: The ignition coil receives low-voltage power from the battery, usually around 12 volts. This low voltage is insufficient to generate a powerful enough spark to ignite the air-fuel mixture in the engine.

- Primary Coil: The ignition coil is made up of two wire coils called the primary coil and secondary coil. The primary coil has fewer turns of wire than the secondary coil and is connected to the battery.

- Magnetic Field Buildup: When the ignition switch is turned on, current flows through the primary coil, resulting in a magnetic field surrounding it. The strength of this magnetic field grows as current travels through the coil.

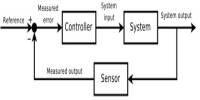

- Interrupting Current: As the magnetic field builds up, the current flowing through the primary coil is suddenly interrupted. This interruption can be caused by the opening of a switch, typically controlled by the engine’s electronic control module (ECM) or ignition module.

- Induced Voltage: When the current through the primary coil is interrupted, the magnetic field collapses rapidly. This collapse induces a high voltage in the secondary coil due to electromagnetic induction. The secondary coil has many more turns of wire than the primary coil, which causes the voltage to increase significantly, sometimes reaching tens of thousands of volts.

- Spark Generation: The secondary coil generates high-voltage electricity, which is delivered to the distributor (in older ignition systems) or directly to the spark plugs (in current ignition systems) via ignition wires. This high voltage generates a spark across the spark plug gap, igniting the air-fuel mixture in the engine’s cylinders.

- Engine Ignition: The spark ignites the compressed air-fuel combination in the combustion chamber, commencing the engine’s power stroke.

Overall, the ignition coil is crucial for starting and running an internal combustion engine efficiently. Problems with the ignition coil can cause engine misfires, rough idling, and problems starting the engine.