Host cell proteins (HCPs) are proteins produced by the host organism, such as a mammalian cell line, during the manufacturing process of a biological medicine. HCPs are process-related protein contaminants created by the host organism during biotherapeutic manufacture and production. Endogenous proteins that are naturally present in the host cell utilized to manufacture the biologic are referred to as HCPs in the context of biopharmaceuticals, notably in the creation of recombinant proteins.

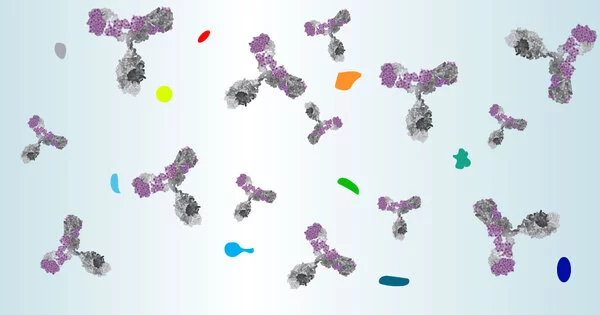

The majority of created HCPs are eliminated from the final product during the purification process (>99% of impurities removed). However, residual HCPs are still present in the finished pharmaceutical medication. Monoclonal antibodies (mAbs), antibody-drug conjugates (ADCs), therapeutic proteins, vaccinations, and other protein-based biopharmaceuticals are examples of HCPs that may stay in the intended pharmaceutical product.

HCPs can co-purify with the target product during biopharmaceutical production, posing potential concerns to the end product’s safety and efficacy. These proteins can contaminate the drug product and cause immunological reactions or other side effects in people who take the medication. As a result, it is critical to monitor and manage HCP levels in the final medication product.

HCPs can cause immunogenicity in people or diminish a drug’s potency, stability, or overall effectiveness. Before pharmaceutical goods are made available to the public, national regulatory organizations such as the FDA and EMA give guidelines on permissible amounts of HCPs that may remain in them. The allowable level of HCPs in pharmaceutical medications currently ranges from 1-100ppm (1-100 ng/mg product). However, the acceptable level of HCPs in a final product is examined on a case-by-case basis and is determined by a variety of parameters such as dose, frequency of medication administration, drug type, and illness severity.

To ensure the purity and safety of the final product, manufacturers employ various purification techniques, such as chromatography, filtration, and other methods, to remove or reduce the levels of HCPs. Additionally, analytical methods, such as enzyme-linked immunosorbent assay (ELISA) and mass spectrometry, are used to detect and quantify the presence of HCPs during the production process.

To assure the safety and efficacy of biopharmaceutical products for patient use, regulatory authorities such as the United States Food and Drug Administration (FDA) and the European Medicines Agency (EMA) have set guidelines and procedures for the evaluation and control of HCPs in biopharmaceutical products. Manufacturers must demonstrate full monitoring and control of HCPs throughout the manufacturing process, as well as evidence of their removal or reduction to acceptable levels in the final drug product.