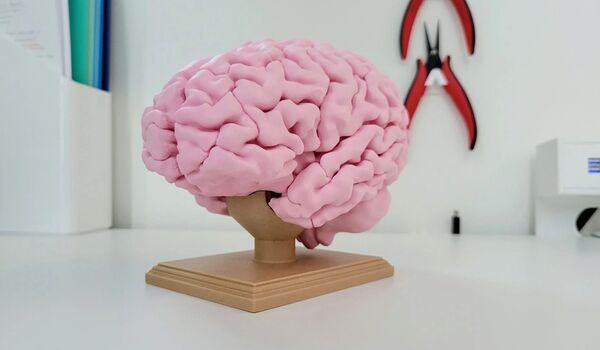

In a collaboration between MedUni Vienna and TU Wien, the world’s first 3D-printed “brain phantom” was created, which is modeled after the structure of brain fibers and can be imaged using a particular version of magnetic resonance imaging. A scientific team led by MedUni Vienna and TU Wien has now demonstrated in a study that these brain models can be used to further research into neurodegenerative disorders such as Alzheimer’s, Parkinson’s, and multiple sclerosis. The findings were published in the journal “Advanced Materials Technologies.”

Magnetic resonance imaging (MRI) is a popular diagnostic imaging method that is mostly used to study the brain. MRI can be used to investigate the structure and function of the brain without using ionizing radiation. Diffusion-weighted MRI (dMRI) is a type of MRI that may also assess the orientation of nerve fibers in the brain. However, determining the direction of nerve fibres at the crossing locations of nerve fibre bundles is extremely difficult since nerve fibres from different directions overlap.

In order to further improve the process and test analysis and evaluation methods, an international team in collaboration with the Medical University of Vienna and TU Wien developed a so-called “brain phantom,” which was produced using a high-resolution 3D printing process.

We see the greatest progress in photography with mobile phone cameras not necessarily in new, better lenses, but in the software that improves the captured images.

Michael Woletz

Tiny cube with microchannels

Researchers from the Medical University of Vienna (MRI experts) and TU Wien (3D printing experts) collaborated with colleagues from the University of Zurich and the University Medical Centre Hamburg-Eppendorf. In 2017, TU Wien created a two-photon polymerisation printer that allows for upscaled printing. In addition, work was done on brain phantoms as a use case in collaboration with the Medical University of Vienna and the University of Zurich. The resulting patent serves as the foundation for the brain phantom, which is now being developed and monitored by TU Wien’s Research and Transfer Support team.

This phantom appears to have little in common with a real brain. It is significantly smaller and shaped like a cube. Inside, it has incredibly small, water-filled microchannels the size of individual cranial nerves. These tubes are five times narrower than a human hair. To replicate the fine network of nerve cells in the brain, the research team led by first authors Michael Woletz (Center for Medical Physics and Biomedical Engineering, MedUni Vienna) and Franziska Chalupa-Gantner (3D Printing and Biofabrication research group, TU Wien) used an unusual 3D printing method: two-photon polymerisation.

This high-resolution approach is generally used to print microstructures in the nanometer and micrometer range, rather than three-dimensional structures in the cubic millimetre region. To develop phantoms suited for dMRI, TU Wien researchers have been working on scaling up the 3D printing process, allowing for the creation of larger objects with high-resolution details. Highly scaled 3D printing gives researchers with very good models that, when viewed through dMRI, allow them to assign distinct nerve structures.

Michael Woletz compares this approach to improving the diagnostic capabilities of dMRI with the way a mobile phone camera works: “We see the greatest progress in photography with mobile phone cameras not necessarily in new, better lenses, but in the software that improves the captured images. The situation is similar with dMRI: using the newly developed brain phantom, we can adjust the analysis software much more precisely and thus improve the quality of the measured data and reconstruct the neural architecture of the brain more accurately.”

Brain phantom trains analysis software

The authentic reproduction of characteristic nerve structures in the brain is therefore important for “training” the dMRI analysis software. The use of 3D printing makes it possible to create diverse and complex designs that can be modified and customised. The brain phantoms thus depict areas in the brain that generate particularly complex signals and are therefore difficult to analyse, such as intersecting nerve pathways.

To calibrate the analysis software, the brain phantom is checked with dMRI and the measured data is analyzed in the same way as a real brain would be. Because of 3D printing, the design of the phantoms is precise, and the results of the analysis can be verified. MedUni Vienna and TU Wien were able to demonstrate that this works as part of their collaborative research efforts. The generated phantoms can be utilized to improve dMRI, which can help with surgical planning and research into neurodegenerative illnesses like Alzheimer’s, Parkinson’s, and multiple sclerosis.

Despite the proof of concept, the team continues to face hurdles. The main challenge at the present is scaling up the method: “The excellent resolution of two-photon polymerisation allows for the printing of details in the micro- and nanometer range, making it ideal for visualizing cranial nerves. At the same time, it takes a long time to print a cube several cubic centimeters in size using this technology,” Chalupa-Gantner adds. “We are therefore not only aiming to develop even more complex designs, but also to further optimise the printing process itself.”